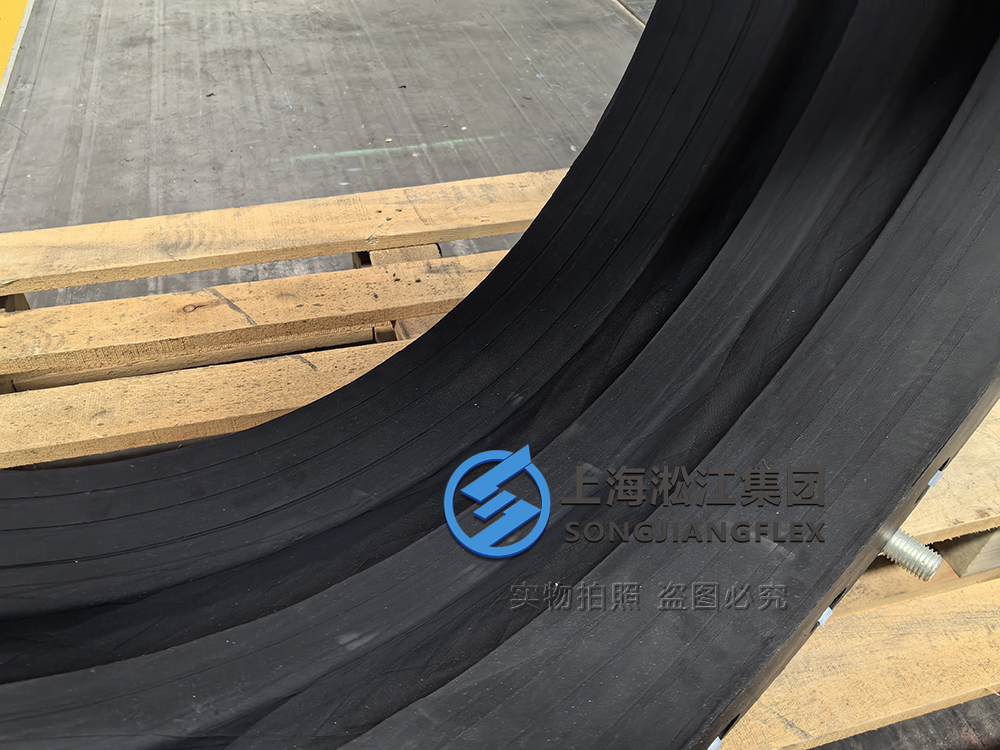

Why Does a DN700 Double-Sphere Wrapped Rubber Expansion Joint Require Special Customization?

Large-diameter pipelines often suffer from excessive vibration, displacement, and stress. Standard rubber expansion joints fail prematurely. Specially customized DN700 solutions address these critical operational risks.

A DN700 double-sphere wrapped rubber expansion joint requires special customization to handle large axial, lateral, and angular movements under high pressure. Custom design ensures correct material selection, reinforcement layers, flange standards, and safety margins, delivering long-term sealing performance and vibration isolation in demanding pipeline systems.

To understand its value, it’s essential to examine the technical challenges behind DN700 pipeline applications.

Why Do DN700 Large-Diameter Pipelines Place Higher Demands on Rubber Expansion Joints?

DN700 pipelines operate with significantly higher internal forces, thermal movement, and vibration loads compared to small-diameter systems, making standard rubber expansion joints insufficient.

As pipe diameter increases, axial thrust, lateral displacement, and vibration energy rise exponentially. DN700 systems amplify these forces, requiring expansion joints with stronger reinforcement, controlled flexibility, and precise structural balance to prevent leakage or fatigue failure.

In applications such as municipal water supply, power plants, district heating networks, and large pump stations, DN700 pipelines are exposed to continuous pressure fluctuations and equipment-induced vibration. Without proper compensation, stress transfers directly to pumps, valves, and pipe supports. Specially designed DN700 rubber expansion joints act as flexible buffers, absorbing movement while protecting the entire system from mechanical damage.

What Is a Double-Sphere Wrapped Structure and Why Is It Superior?

The double-sphere wrapped structure is specifically engineered to enhance flexibility and load distribution in large-diameter rubber expansion joints.

Compared with single-sphere designs, double-sphere wrapped expansion joints offer greater movement capacity, improved vibration isolation, and reduced stress concentration, especially critical for DN700 and above.

The dual-arch geometry allows axial and lateral movements to be shared across two flexible zones, lowering fatigue stress on each convolution. Wrapped reinforcement layers, typically multi-ply fabric cords, improve pressure resistance and prevent excessive deformation. This structure ensures stable performance even under repeated thermal cycles and long-term vibration exposure.

Which Parameters Can Be Specially Customized for a DN700 Double-Sphere Rubber Expansion Joint?

Special customization goes far beyond size scaling and focuses on precise matching with actual operating conditions.

Key customizable parameters include flange standards, face-to-face length, pressure rating, rubber compound, reinforcement layers, and allowable displacement, ensuring optimal compatibility with the pipeline system.

Customization options may include DIN, ANSI, or GB flanges, vacuum-resistant designs, and rubber materials such as NR, EPDM, or NBR based on media and temperature. Reinforcement ply count and wrapping angles are adjusted according to pressure requirements. These tailored details significantly improve sealing reliability and operational safety in DN700 installations.

How Does Special Customization Improve Safety and Service Life?

The primary goal of customization is not complexity, but long-term reliability and system safety.

By matching real working conditions, customized DN700 expansion joints reduce overstress, prevent pull-out failure, and extend service life under continuous operation.

Incorrectly selected expansion joints often fail due to overextension, internal pressure thrust, or vacuum collapse. Customized designs incorporate anti-pull rings, reinforced carcasses, and safety factors tailored to actual loads. This significantly lowers maintenance frequency, minimizes unplanned shutdowns, and protects critical equipment connected to large-diameter pipelines.

Which Industries and Projects Benefit Most from DN700 Special Custom Rubber Expansion Joints?

Not all projects require customization, but high-risk and high-value systems benefit the most.

DN700 customized rubber expansion joints are ideal for power generation, municipal infrastructure, chemical plants, and overseas engineering projects with complex operating conditions.

Industries handling high flow rates, corrosive media, or continuous operation demand higher reliability. Municipal water networks, thermal power stations, desalination plants, and export-oriented EPC projects often specify customized full-faced rubber expansion joints to ensure compliance, durability, and long-term system stability across varying environmental and operational conditions.

Summary

Specially customized DN700 double-sphere wrapped rubber expansion joints ensure safety, durability, and precise performance where standard solutions cannot meet demanding pipeline requirements.