Technical Information

Precise Isolation, Stable and Reliable

Rubber Vibration Isolator Mounts

What They Are

Rubber vibration mounts are highly effective solutions for controlling vibration and protecting equipment. Their primary function is to reduce the transmission of excitation forces between vibrating machinery and the supporting structure, thereby extending equipment lifespan and improving operational stability. Acting like a “spring,” these mounts store energy generated by external vibrations and release it once the force subsides. This energy release helps counteract incoming vibrations, significantly reducing transmitted forces.

A successful vibration mount design relies on selecting a natural frequency that does not coincide with the excitation frequency of the equipment. By optimizing this frequency ratio, the risk of resonance is minimized, ensuring maximum vibration isolation performance. Made from high-elasticity engineered rubber, these mounts can recover up to 97% of stored energy, offering both efficient vibration reduction and long-lasting durability.

Rubber vibration mounts are widely used in industrial machinery, generators, HVAC systems, and other vibration-sensitive equipment. Whether isolating heavy machinery or controlling micro-vibrations in precision instruments, they provide reliable protection and are an essential component of modern vibration control solutions.

How They Work – Vibration Isolation Principles

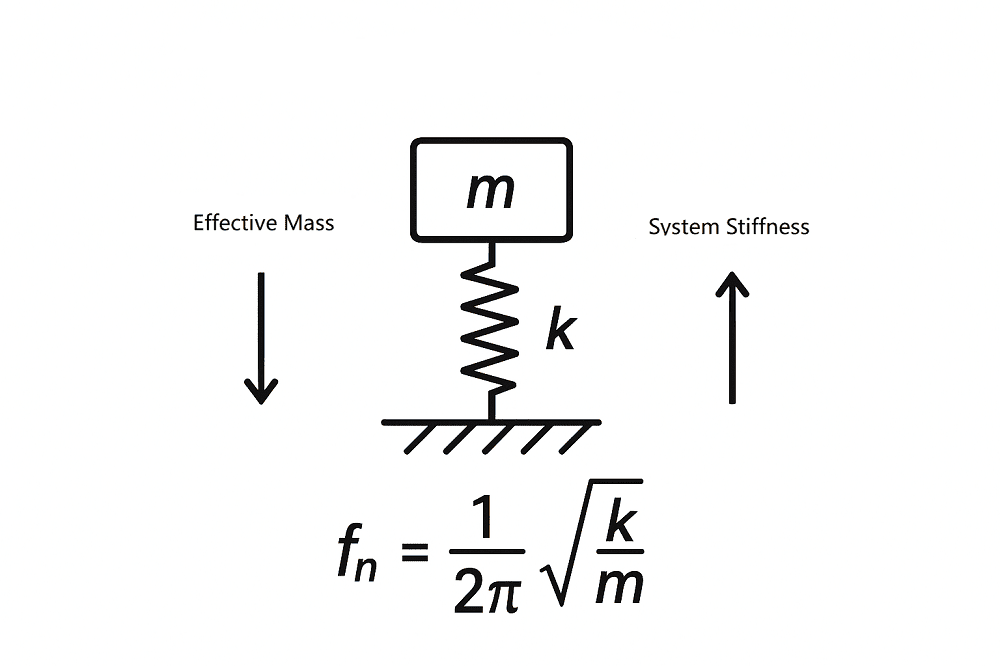

Natural Frequency(fn)

What is natural frequency?

Natural frequency, also commonly referred to as a system’s resonant frequency, is the inherent rate at which a system vibrates when subjected to a small disturbance without continuous external forces. It is primarily influenced by the stiffness of the supporting springs, the mass of the suspended equipment, and the rotational inertia of the system. Each component in a mechanical system affects the overall dynamic response, and careful evaluation is required to avoid unnecessary vibrations. Understanding natural frequency is crucial in the design of vibration isolation systems. It determines how the suspended mass responds to external excitations and directly impacts the stability and performance of machinery. Ignoring this factor can lead to resonance, excessive vibrations, and even equipment damage. By optimizing system parameters, engineers can ensure reliable operation and extend the lifespan of the equipment.

Factors Affecting Natural Frequency

The natural frequency of a system is the frequency at which it oscillates naturally when disturbed from its equilibrium position, without any external forcing. It is a fundamental characteristic of any mechanical or structural system and depends on the system’s mass and stiffness.

For a single-degree-of-freedom (SDOF) system, the natural frequency can be calculated using the formula mentioned above.

A higher stiffness or a lower mass results in a higher natural frequency, while a lower stiffness or a higher mass results in a lower natural frequency. Accurately identifying the natural frequency is crucial in vibration control, as resonance occurs when the external excitation frequency matches the natural frequency, leading to excessive vibration.Therefore, it is crucial to perform a comprehensive analysis of the system to avoid resonance.

Forcing Frequency

Forcing Frequency refers to the frequency of an external excitation or force acting on a system. It represents how often the system is driven by an external force per unit time. External excitations can come from rotating machinery (such as motors or pumps), vibration equipment, or environmental disturbances (such as earthquakes or traffic vibrations). The system responds with vibrations according to the frequency of the applied force.

For example, the rotational frequency of a motor rotor represents the forcing frequency acting on the system. Similarly, wind or ground vibrations acting on a building also generate vibrations at the corresponding forcing frequency.

Resonance

Resonance occurs when the forcing frequency acting on a system is equal to or very close to the system’s natural frequency, causing the vibration amplitude of the system to increase significantly.

Characteristics and Explanation:

Amplitude Amplification: Even a small external excitation can cause large vibrations in the system.

Energy Accumulation: External energy accumulates within the system, further increasing the vibration.

Potential Hazards: If uncontrolled, resonance can lead to mechanical damage, structural failure, or even safety accidents.

Examples:

A suspension bridge experiences strong oscillations when pedestrians walk in sync.

When the rotational frequency of a motor or pump is close to the natural frequency of its supporting structure, noticeable vibrations occur.

Avoiding Resonance Without Modifying the System

Even without altering the system’s mass or stiffness, resonance can be avoided or mitigated through the following methods:

Control the External Forcing Frequency

Adjust the operating speed or frequency of external equipment so that the forcing frequency does not match the system’s natural frequency.

Example: Varying motor speed or pump operation frequency.

Increase Damping

Install dampers, vibration absorbers, or isolators to absorb vibrational energy, reducing vibration amplitude even when the forcing frequency is close to the natural frequency.

Modify the Excitation Method

Use asynchronous operation, intermittent operation, or distributed excitation to prevent the external force from concentrating at a single frequency.

Isolate or Absorb External Vibrations

Introduce vibration isolation devices or flexible connections between the system and the source of vibration to reduce the transmission of external excitations.

In summary, resonance can be effectively managed without changing the system itself by controlling the external excitation and applying damping or isolation techniques.

Rubber

The Role and Features of Rubber

Rubber is the core material of vibration isolator mounts. With excellent elasticity, flexibility, and damping performance, it effectively absorbs and dissipates vibration energy.

Elasticity and Flexibility: Rubber deforms under external force and quickly recovers after the force is removed. This property enables it to cushion shocks and reduce the transmission of vibration energy.

Damping Properties: The internal molecular structure of rubber has frictional characteristics, which consume part of the energy during deformation and recovery, reducing vibration amplitude.

Environmental Resistance: Different types of rubber can be selected depending on the application, such as NBR (nitrile rubber), Neoprene, or NR (natural rubber). Each provides resistance to oil, aging, wear, and adapts to various working conditions.

Noise Reduction: Rubber not only isolates vibration but also reduces noise transmission, creating a quieter working environment.

Vibration Isolator Mount

The Structure and Design of the Mount

Rubber isolators are not just rubber blocks; they are combined with metal or composite mounting structures to ensure reliable installation and optimal vibration control.

Metal Housing/Base: Usually made of steel or aluminum alloy, the housing provides structural strength and ensures the rubber is securely fixed between the equipment and foundation.

Installation Method: The mount is often designed with bolt holes, threads, or embedded fittings, making it easy to fasten equipment to the base.

Mechanical Design: The combination of the rubber element and mount is carefully engineered to balance load capacity and vibration isolation. This ensures both vertical and horizontal stability.

Anti-Pull-Out Feature: For heavy-duty vibration conditions, some mounts include metal limiters or anti-pull-out devices to prevent rubber failure under excessive tension.

Conclusion

Rubber provides flexibility, damping, and vibration absorption.

The mount structure ensures stability, strength, and reliable installation.

Together, rubber vibration isolator mounts effectively absorb vibrations and shocks generated during equipment operation, reduce energy transmission, extend equipment lifespan, and improve working environment comfort.