Quality

Songjiangflex: Commitment to Product Quality

Product Quality Control

Our factory takes pride in supplying high-quality rubber engineering components to the industrial OEM market. With over 30 years of expertise in manufacturing rubber vibration isolators and engineering components, we fully understand the critical importance of stringent quality control in the rubber industry and the exacting standards expected by OEM clients.

To ensure every product meets the highest standards, we have established comprehensive in-house testing facilities that rigorously evaluate both mechanical performance and material quality. This commitment to excellence and precision has earned us a reputation for reliability and professionalism in the industry.

Over the years, our products have been exported to countries including Turkey, Germany, and other regions, serving well-known global companies with customized solutions. We take pride in consistently delivering premium rubber components, with quality embedded in every product we produce.

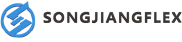

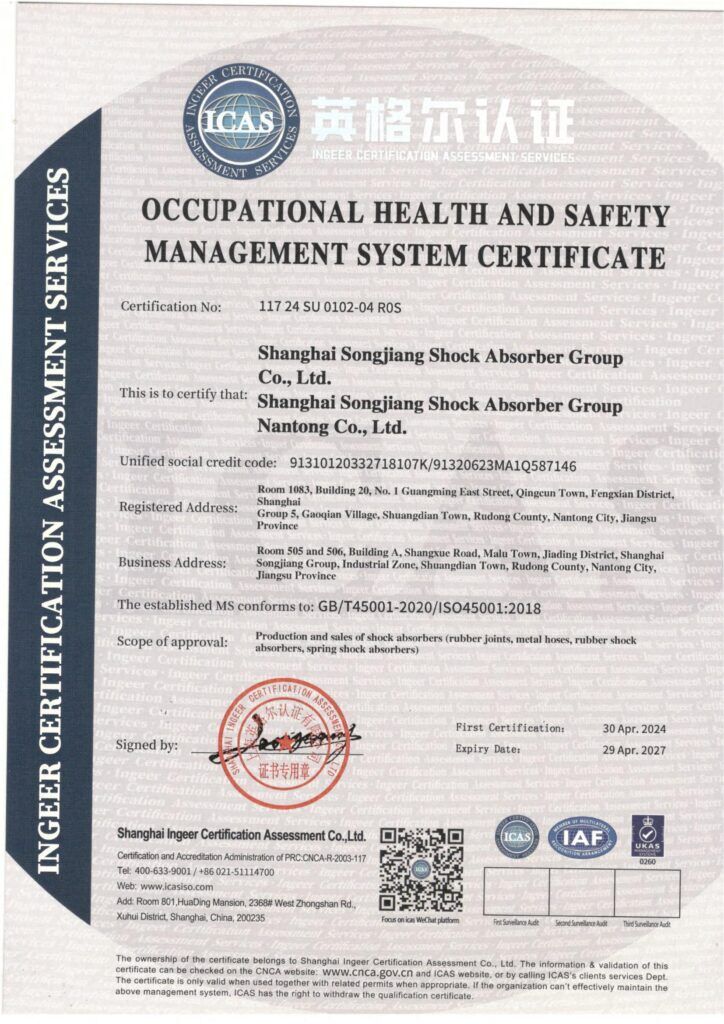

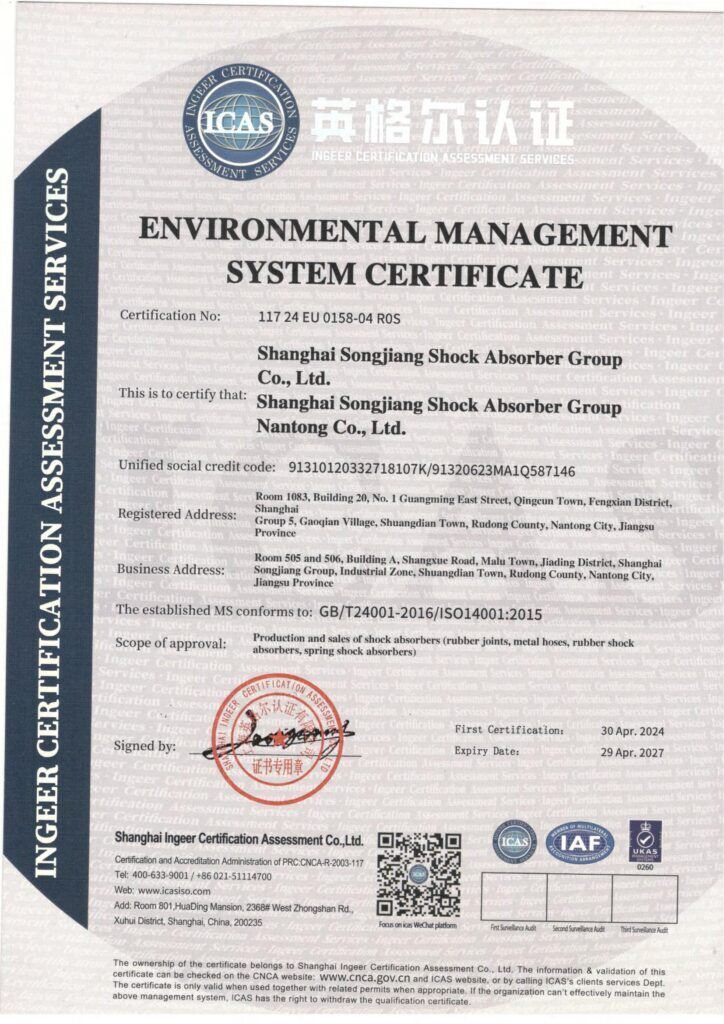

Our company has obtained a comprehensive range of international and domestic certifications, underscoring our unwavering commitment to product quality and safety. We are ISO9001:2015 certified, ensuring our quality management system consistently meets global standards. Our OHSAS18001 occupational health and safety certification and ISO14001 environmental management certification demonstrate our dedication to safe, responsible, and sustainable manufacturing practices.

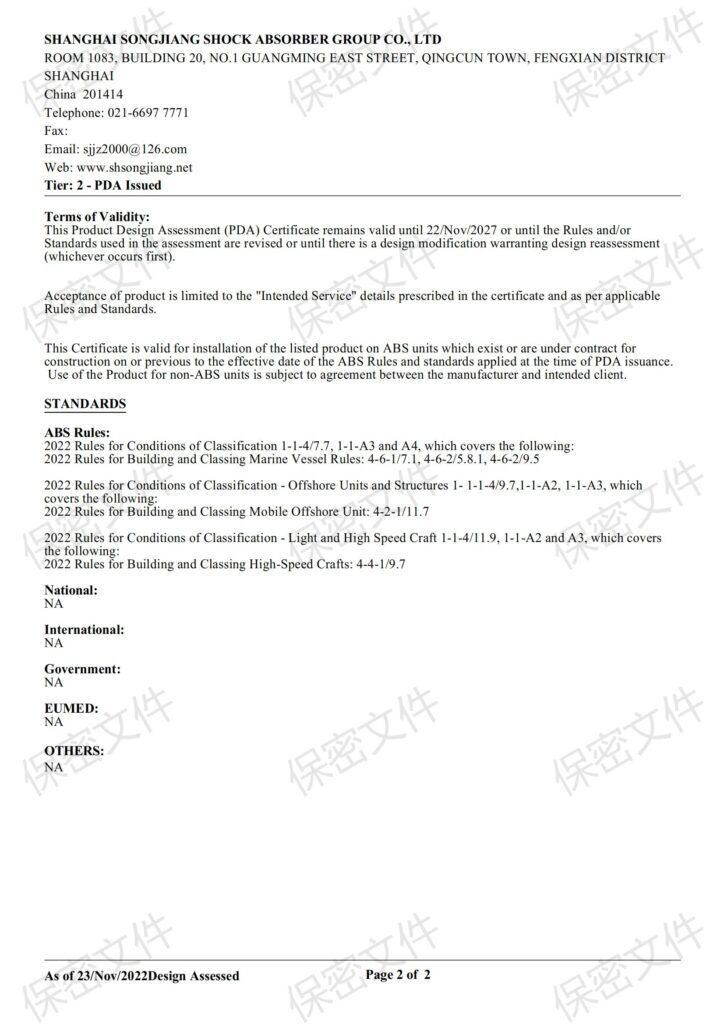

In addition, we are in the process of obtaining CCS certification from the China Classification Society and have secured ABS certification from the United States, reflecting our capability to meet stringent maritime industry standards. Our products also comply with drinking water hygiene approvals and have been verified through flame-retardant rubber testing reports, guaranteeing both safety and performance.

These certifications are not merely formalities—they reflect our rigorous internal quality controls, advanced testing facilities, and adherence to the highest standards in every stage of production. As a result, our customers can trust that every rubber component, vibration isolator, or engineering part we deliver meets the highest levels of quality, safety, and reliability.

Certification Overview

Quality Assured: Product Testing & Inspection

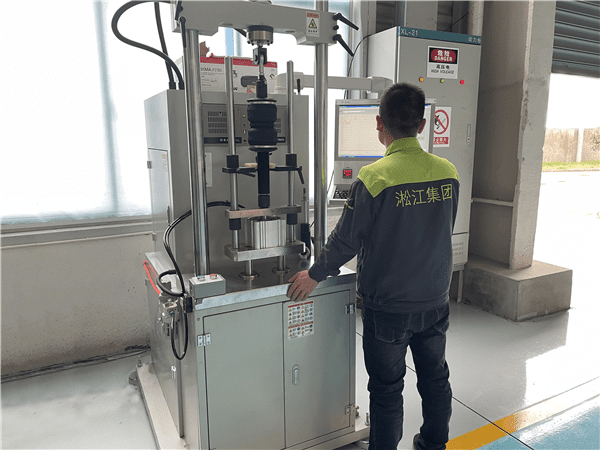

In our laboratory, quality engineers utilize multiple universal testing machines to conduct systematic evaluations of rubber components. Key parameters measured include compression stiffness, tensile strength, shear performance (Kg/mm), bonding strength, compressive deformation, and damping characteristics.

Our advanced testing facilities allow both static and dynamic cyclic tests, accurately simulating the load and environmental conditions that products encounter in real-world applications. Accelerated lifetime testing can also be performed to validate long-term reliability and durability.

In addition, we have the capability to design and manufacture custom fixtures and samples for specialized evaluations such as shear, compression, and tensile force testing. This ensures that all products remain within strict working tolerances throughout production and quality control processes.

Universal Testing Machine (UTM)

Shock Absorber Dynamometer

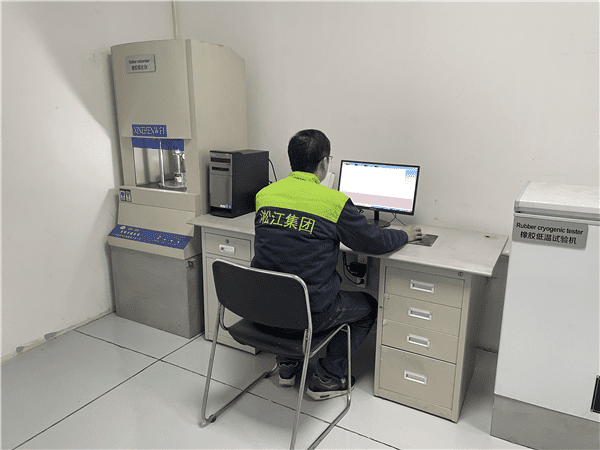

Rubber Rheometer

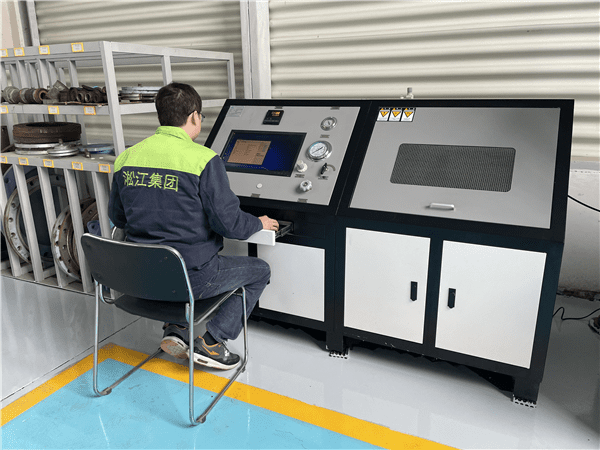

Burst Testing Machine

Laboratory Internal Mixer for Rubber Batch Compounding

Rubber compounding is a complex process, requiring the precise blend of polymers, fillers, curing agents, and additives to achieve optimal performance. Most compounds look similar, making it hard to distinguish quality and formulation by appearance alone.

Our fully automatic rubber batch dosing machine accurately measures material ratios and performs chemical analysis to generate precise formulations. Using our small-scale internal mixer, we produce test batches for quality verification before full-scale production. This ensures consistent performance while minimizing material waste, delivering reliable, high-quality rubber products every time.

Fully Automatic Small-Scale Rubber Dosing Machine

Laboratory-Scale Rubber Internal Mixer

Quality First, Trusted Worldwide

At the heart of long-term business success lies product quality. Advanced technology and strong marketing are meaningless if products cannot meet customer expectations for performance and reliability. High-quality products minimize after-sales issues, reduce waste, and deliver real value, fostering lasting partnerships. By making quality our core strength and maintaining rigorous production control, our company has become the trusted choice for leading companies around the globe.