Single Sphere Rubber Expansion Joint

Single-Bellow Rubber Expansion Joint – Perfect Fit for Every Pipeline

Single Sphere Rubber Expansion Joint

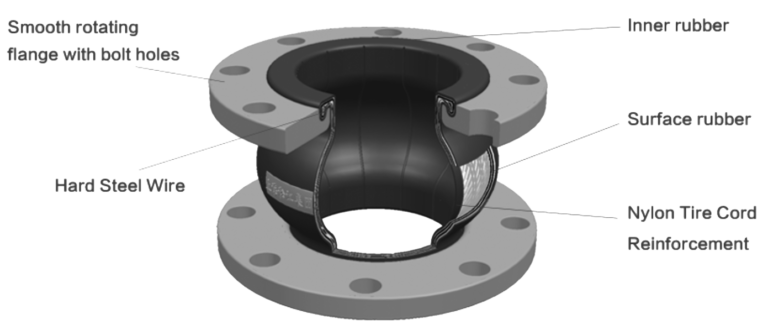

A Single Sphere Rubber Expansion Joint is a specialized flexible connector designed to accommodate movements, reduce stress, and absorb vibrations in piping systems. Its defining feature is the single spherical rubber element, which allows the joint to flex in multiple directions, including axial, lateral, and angular movements. Unlike multi-sphere or convoluted expansion joints, the single sphere design is compact and provides a simpler geometry while maintaining high elasticity and pressure resistance.

The core working principle of this joint relies on the elastic deformation of the rubber body. When the pipeline experiences expansion due to temperature changes, pressure fluctuations, or mechanical vibration, the rubber element compresses or stretches, redistributing stress along the pipeline. This reduces the risk of pipe fatigue, flange leaks, and structural damage to connected equipment. The spherical shape provides uniform stress distribution, minimizing localized deformation and preventing premature material failure.

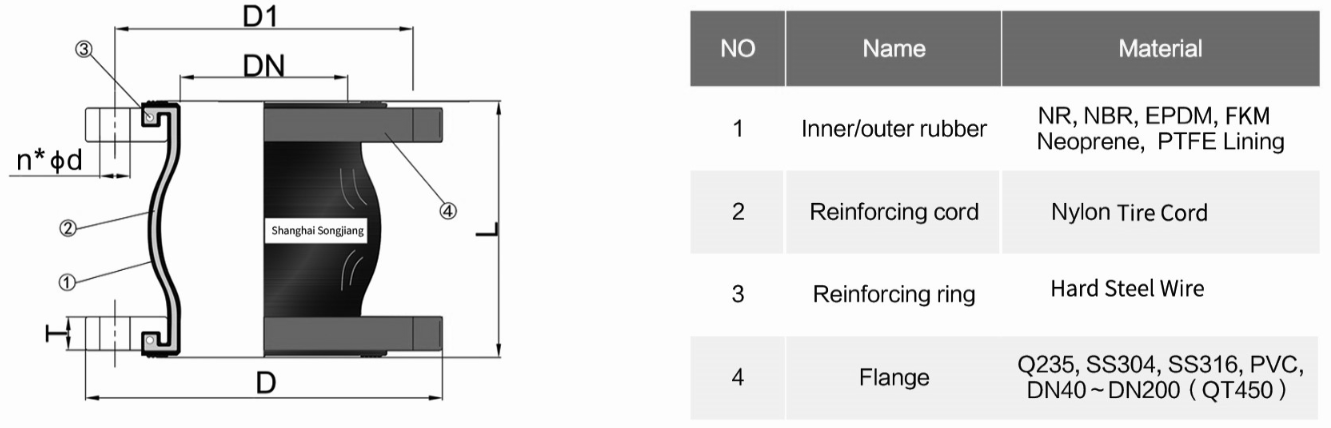

Typically, the rubber is reinforced with fabric layers or cord reinforcements, enhancing the mechanical strength while retaining flexibility. The flanges, usually made from steel, stainless steel, or aluminum, secure the joint to the piping system. They are often drilled to match standard pipe dimensions (ANSI, DIN, or JIS), allowing for straightforward integration without modifying existing pipelines. The flexibility of the joint also compensates for minor misalignments, a common issue in industrial installations where perfect alignment is rarely achievable.

Single Sphere Rubber Expansion Joints are widely used in chemical plants, water treatment systems, HVAC pipelines, marine applications, and power generation systems. In chemical processing, for instance, these joints handle slight axial expansion in high-temperature pipelines carrying corrosive fluids. In HVAC systems, the joints isolate vibrations from pumps and fans, improving comfort and protecting ductwork from fatigue.

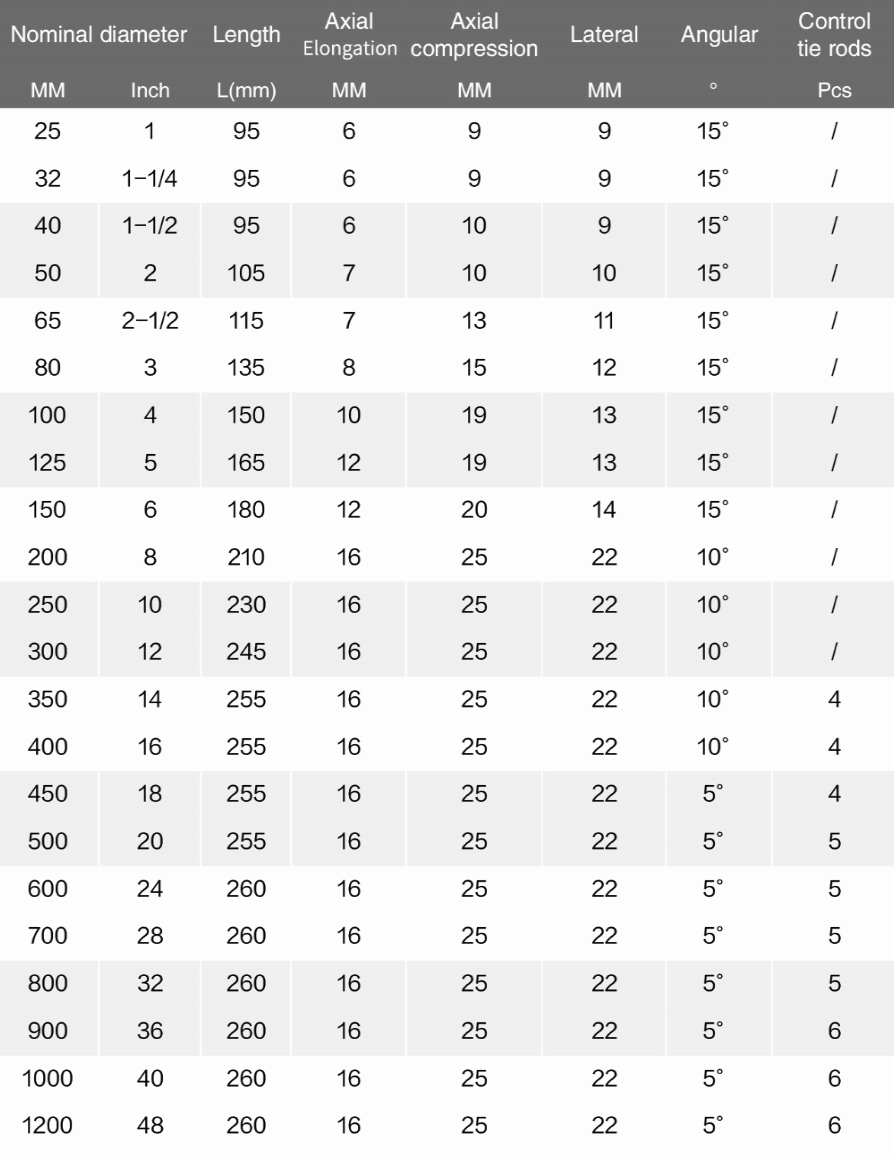

A properly designed single sphere joint ensures reliable sealing under pressure, high vibration attenuation, and longevity. Selection involves evaluating parameters such as nominal diameter, operating pressure, expected movement, and chemical compatibility. Engineering calculations often include finite element analysis (FEA) to simulate stress distribution under various loading conditions, ensuring the joint can withstand both normal operation and occasional extreme events, such as water hammer or thermal shock.

In summary, the Single Sphere Rubber Expansion Joint is a critical component for industrial pipelines requiring flexibility, vibration damping, and thermal movement compensation. Its simple yet robust design balances cost, performance, and ease of installation, making it a preferred choice for moderate movement applications across multiple industries.

The choice of rubber material in a Single Sphere Rubber Expansion Joint is crucial, as it directly impacts performance, chemical resistance, temperature tolerance, and service life. Common materials include EPDM, NBR (Nitrile Rubber), Neoprene, Silicone, and Fluoroelastomers (Viton/FKM). Each material has distinct advantages depending on the application.

EPDM is widely used due to its excellent resistance to hot water, steam, ozone, and weathering. It can typically withstand continuous temperatures up to 120°C, making it ideal for HVAC systems, hot water lines, and chemical pipelines that are not exposed to aggressive hydrocarbons. EPDM also exhibits high flexibility, which enhances vibration absorption and compensates for axial and lateral movement.

Nitrile Rubber (NBR) is highly resistant to oils, fuels, and certain chemicals. It is commonly used in automotive pipelines, fuel lines, and hydraulic systems where oil exposure is frequent. NBR has a moderate temperature range, generally up to 100–120°C, and provides good mechanical strength under dynamic conditions.

Neoprene offers a balance between chemical resistance and mechanical durability. It resists ozone, weathering, and mild acids, making it suitable for outdoor pipelines and marine applications. Neoprene joints are often selected when vibration damping is critical and the medium is moderately aggressive.

Silicone is preferred for extremely high-temperature applications, reaching up to 250°C. It maintains flexibility at elevated temperatures but has limited mechanical strength compared to EPDM or NBR. Silicone is widely used in exhaust systems, high-temperature steam lines, and food or pharmaceutical pipelines where chemical inertness is required.

Fluoroelastomers (Viton/FKM) provide excellent chemical resistance, including to aggressive fuels, solvents, and acids, while also tolerating temperatures up to 200–250°C. These materials are typically used in chemical processing, petroleum, and high-performance industrial applications.

Material selection should consider several factors:

Operating temperature and pressure: Ensure the rubber can withstand both continuous and peak conditions.

Chemical compatibility: Verify the medium will not degrade the rubber over time.

Mechanical stress: Consider axial, lateral, and angular movements, as well as vibration frequencies.

Environmental conditions: For outdoor applications, UV and ozone resistance are critical.

Longevity requirements: High-performance materials may offer longer service life but at a higher cost.

In practice, engineers often consult chemical compatibility charts, perform accelerated aging tests, and analyze pipeline movement requirements to ensure the selected material meets all operational demands. Proper selection not only enhances performance but also reduces maintenance costs and downtime.

Single Sphere Rubber Expansion Joints play a critical role in mitigating vibration and noise in industrial piping systems. Vibrations originate from multiple sources, including pumps, compressors, fans, fluid turbulence, and mechanical equipment. If transmitted through rigid pipelines, these vibrations can cause structural fatigue, leaks, and even equipment failure.

The rubber body of the joint acts as a high-damping element, absorbing vibrational energy and converting it into minimal heat. The spherical geometry further improves performance by allowing multidirectional flexibility, ensuring that axial, lateral, and angular movements are effectively accommodated. Unlike rigid metal connectors, these joints do not transmit vibrations directly to adjacent equipment or supports, significantly reducing operational noise and protecting sensitive machinery.

Industrial case studies show that installing single sphere expansion joints in pump discharge lines or HVAC duct connections can reduce vibration amplitudes by 40–60%, while noise levels can drop by 5–10 dB, depending on system design. This is particularly critical in environments such as laboratories, hospitals, marine vessels, and precision manufacturing facilities, where vibration and noise control are essential for performance and comfort.

The damping efficiency depends on the rubber hardness (Shore A), thickness, and the presence of reinforcement layers. Softer compounds provide higher vibration absorption but may have lower pressure resistance. Conversely, harder compounds offer greater structural integrity but slightly reduced damping. Engineers typically balance these parameters based on system requirements.

Additionally, these joints can help prevent water hammer and pressure surge damage, as the elastic rubber element temporarily absorbs sudden pressure spikes. This dual function—vibration isolation and pressure surge mitigation—makes them highly versatile for industrial pipelines.

Proper installation and maintenance are critical to achieving the full performance and lifespan of Single Sphere Rubber Expansion Joints. Poor installation is one of the leading causes of early joint failure.

Installation guidelines:

Alignment: Flanges must be aligned precisely; angular misalignment should not exceed design limits. Misalignment causes uneven stress distribution and reduces service life.

Axial compression/extension: Avoid pre-compressing or over-extending the joint. Most single sphere joints have defined axial movement limits—exceeding them can cause tearing or flange separation.

Flange torque: Bolts should be tightened evenly in a crisscross pattern according to recommended torque values. Uneven tightening leads to localized stress and potential leaks.

Supports and anchors: Pipes must be adequately supported, and anchors should control directional movement, ensuring the joint absorbs only the intended displacement.

Cleaning and preparation: Avoid sharp tools or abrasive cleaners; minor debris can damage the rubber surface or cause leaks.

Maintenance practices:

Visual inspection: Look for cracks, blisters, or signs of chemical attack. Early detection allows for preventive replacement before failure.

Movement check: Ensure that the pipeline movement remains within the joint’s rated capacity.

Torque check: Re-tighten bolts if necessary, especially after initial pressure testing.

Environmental protection: UV-exposed joints should be shielded or coated to prevent premature aging.

Routine inspection schedules are typically every 6–12 months, depending on operating conditions. Correct installation and proactive maintenance can extend service life to 10–15 years under normal industrial conditions.

Yes, customization is a key advantage of single sphere rubber expansion joints. Standard models may suffice for moderate movement applications, but specific industrial requirements often necessitate tailored solutions. Customization parameters include diameter, pressure rating, rubber material, reinforcement layers, flange type, and movement capabilities.

For instance, in chemical processing plants, pipelines may carry corrosive acids at high temperatures. Standard EPDM joints might fail under these conditions, so engineers may opt for Viton rubber with stainless steel flanges and additional cord reinforcement to maintain integrity. Similarly, marine applications require joints resistant to saltwater corrosion and mechanical vibration, often involving Neoprene compounds with coated or galvanized flanges.

Movement requirements can also dictate custom design. Some applications demand larger lateral or angular deflection than standard joints can provide. In such cases, the rubber thickness, sphere diameter, and reinforcement layers are adjusted to accommodate these movements without compromising pressure capacity.

Custom joints are also important for space-constrained installations. Engineers may design compact single sphere joints to fit between existing equipment while maintaining required flexibility and pressure ratings. For industries like food, pharmaceutical, and semiconductor manufacturing, materials must be FDA-approved or cleanroom compatible, further emphasizing the need for customization.

In summary, the adaptability of single sphere rubber expansion joints makes them suitable for diverse industries: water treatment, HVAC, chemical processing, marine, power generation, and more. Customization ensures that the joint performs optimally under specific operational conditions, balancing movement absorption, vibration damping, chemical resistance, and mechanical integrity.

Customization Options for Flanges and Single Bellow

| Option | Flange Material | Flange Standards | Sphere (Bellow) Material |

|---|---|---|---|

| 1 | Cast Iron | ANSI (American National) | NR (Natural Rubber) |

| 2 | Carbon Steel | DIN (German Standards) | NBR (Nitrile Butadiene Rubber) |

| 3 | Stainless Steel | JIS (Japanese Standards) | EPDM |

| 4 | Brass | BS (British Standard) | CR (Chloroprene) |

| 5 | Aluminum Alloy | Chemical Industry Standards | FKM (Fluoroelastomer) |

| 6 | PVC | Marine Standards | Silicone |

| 7 | Other Materials | Custom Non-Standard | PTFE Lining |

Structure of Rubber Expansion Joint

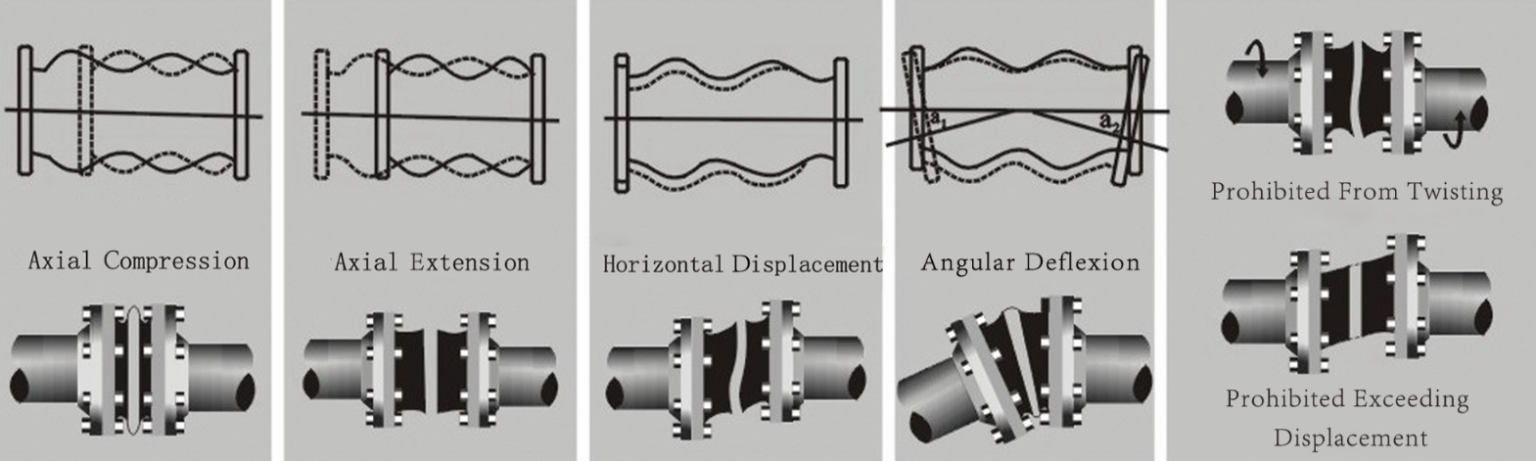

Displacement Mode Diagram of Rubber Expansion Joints

Installation Diagram of Single Sphere Rubber Expansion Joint