SAE Rubber Compensator

High-Performance Rubber Expansion for Industrial Excellence

SAE Rubber Compensator

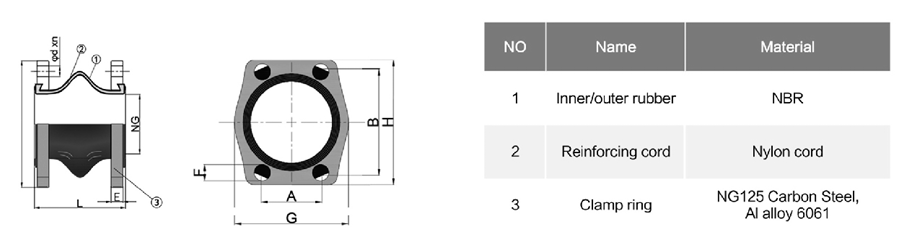

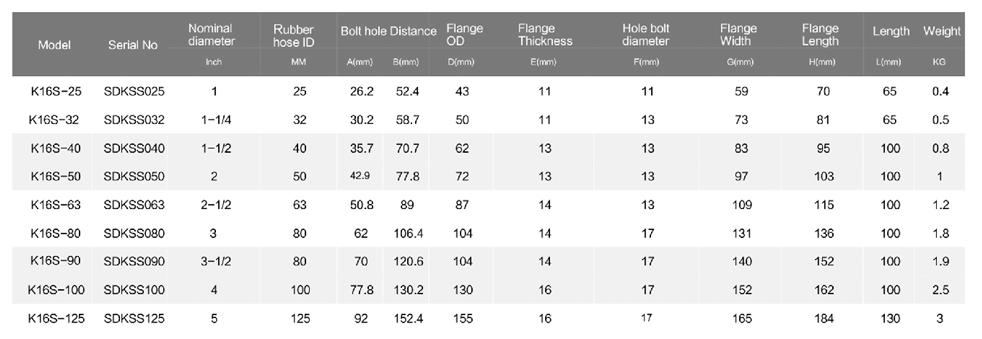

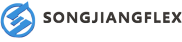

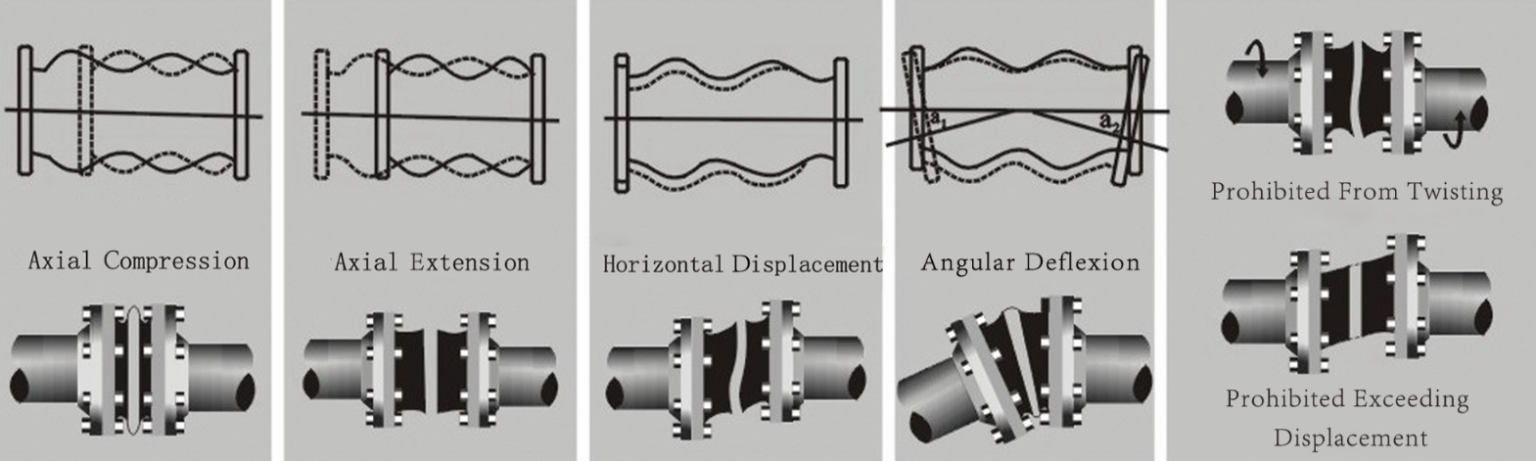

The primary function of an SAE Rubber Compensator is to act as a flexible connector that absorbs movement, reduces vibration, and compensates for mechanical misalignment across different types of systems. Its structure typically consists of high-elasticity rubber combined with reinforced fiber layers, enabling it to absorb axial, lateral, and angular displacement within a piping or mechanical system. This flexibility helps prevent stress concentration and reduces mechanical fatigue, which ultimately protects equipment from cracks, leaks, or premature failure.

In pipeline applications, the compensator helps manage thermal expansion, pump vibration, pressure fluctuations, and mechanical misalignment. Water systems, HVAC lines, cooling circuits, oil pipelines, and chemical transport lines all benefit from the compensator’s ability to minimize vibration transfer and protect pumps, valves, and flow meters.

In the automotive field, SAE rubber compensators are commonly used in engine cooling circuits, exhaust lines, hydraulic systems, and vibration control components. Vehicles often operate under dynamic loads, accelerating, braking, and experiencing constant vibration. The compensator provides damping, stabilizes the system, and improves ride comfort while also protecting hoses, radiators, and heat exchangers.

Within marine and shipbuilding industries, rubber compensators are exposed to harsh working conditions such as hull vibration, wave impact, engine noise, and pressure surges. Their excellent vibration-damping capability helps prevent damage to onboard equipment, reduces noise levels inside cabins, and increases the reliability of cooling water lines, fire-fighting pipelines, and seawater-intake systems.

Because SAE-based designs follow strict standards for durability, pressure tolerance, material quality, and uniformity, these compensators are trusted solutions across multiple industries. They provide excellent mechanical flexibility, high vibration isolation efficiency, corrosion resistance, and long-term reliability. For this reason, SAE Rubber Compensators have become essential components across pipeline engineering, automotive manufacturing, marine installations, and industrial machinery.

An SAE Rubber Compensator is commonly made from several types of rubber compounds, each selected according to its specific performance characteristics and resistance to temperature, medium, and environmental conditions. The most widely used materials include EPDM, NBR, CR, FKM, and NR, each reinforced with high-strength nylon cord, synthetic fiber fabric, or steel wire layers.

EPDM is known for its superior resistance to heat, steam, UV rays, and aging. It performs exceptionally well in hot water, air, HVAC systems, and chemical environments. However, EPDM is not suitable for oil-based fluids or fuels.

NBR (Nitrile Rubber) is the preferred material for oil, fuel, lubricants, and hydraulic fluids. It offers excellent oil resistance but is more sensitive to ozone and sunlight, meaning additional protective coatings may be required in outdoor environments.

CR (Neoprene Rubber) provides balanced performance: moderate oil resistance, good weather resistance, and natural flame retardancy. This makes it especially suitable for automotive engine compartments and marine engine rooms.

FKM (Fluorocarbon Rubber) is used for high-temperature and highly corrosive environments. It withstands aggressive chemicals, fuel vapors, and very high temperatures, making it ideal for heavy-duty industrial and petrochemical use.

NR (Natural Rubber) offers exceptional elasticity and vibration-damping ability. Its high resilience makes it ideal for machinery that requires strong shock absorption, but it has limitations in chemical resistance and high-temperature environments.

Flanges are typically manufactured from carbon steel, stainless steel, or galvanized steel to ensure strength and corrosion resistance. The internal reinforcing layers determine the compensator’s pressure rating, fatigue resistance, and durability.

By selecting the correct rubber for the specific medium—water, air, oils, chemicals, or seawater—the service life and reliability of the compensator can be significantly improved. Proper material selection is directly linked to long-term stability, safety performance, and cost efficiency.

SAE Rubber Compensators typically support pressure ratings of PN10, PN16, or higher, depending on the number of reinforcing plies, rubber thickness, and flange type. Their standard temperature range spans from -20°C to +120°C, suitable for most water and HVAC applications. When high-temperature rubber types such as silicone or fluorocarbon (FKM) are used, the upper temperature limit may increase to 150°C or even 180°C.

However, the safe operating range of the compensator depends heavily on the fluid medium. For example, EPDM performs well with hot water but poorly with oil. NBR is ideal for oil but unsuitable for high-ozone environments. Chemical resistance must always be evaluated based on the actual medium being transported.

In pipeline systems with strong pressure pulsation, sudden loading, or pump startup shock waves, the compensator must be selected with a stronger reinforcement structure. In automotive and marine systems, vibration frequency can be very high, so fatigue resistance becomes a key factor.

There are several limitations to consider:

The compensator should never be over-stretched, over-compressed, or twisted beyond its design limits.

The installation should avoid pre-stress; the product must be installed at its natural length.

Continuous high temperature accelerates rubber aging, reducing elasticity and increasing the risk of cracking.

Certain chemical media may cause rubber swelling or degradation, affecting structural strength.

Proper selection based on pressure, temperature, and medium compatibility ensures maximum performance and long-term reliability.

To ensure the SAE Rubber Compensator operates at its best, the installation process must be done carefully and according to engineering standards. First, the pipeline must be in a natural, stress-free state before installation. The compensator should never be used to correct misalignment or fill pipe gaps, as this will place excessive load on the rubber body and reduce its service life.

Flange faces should be clean, flat, and properly aligned. Bolts must be tightened gradually in a star-shaped cross pattern to distribute pressure evenly around the flange. Over-tightening can compress the rubber excessively and lead to deformation.

In environments with high heat—such as near engines, boilers, or exhaust systems—thermal shielding should be installed to protect the rubber from direct heat exposure. For corrosive media, internally lined models or chemically resistant rubber types should be used, and an external protective coating may be required.

When used at the pump discharge side, it is recommended to keep a short, straight pipe section between the pump and compensator, reducing the impact of pulsating pressure. In equipment with strong vibration (marine engines, diesel generators, compressors), compensators should be paired with tie rods, limit devices, or control rods to prevent excessive displacement.

After installation, a system pressure test and leak check are essential. Periodic inspections should be conducted to detect signs of aging, hardening, cracking, swelling, or flange loosening. Proper installation and maintenance will greatly extend the operational life of the compensator and improve system stability.

The typical service life of an SAE Rubber Compensator ranges from 3 to 8 years, but the actual lifespan depends on operating conditions, rubber material selection, environmental exposure, and maintenance practices.

High temperatures accelerate rubber aging, causing hardening, surface cracks, and reduced elasticity. Continuous pressure surges or water hammer can shorten its life due to repeated stress cycles. Aggressive chemicals may lead to swelling or softening. For example, EPDM deteriorates quickly in oil-based environments, while NBR is not ideal for ozone-rich or outdoor environments without additional protection.

Excessive vibration from engines, pumps, or rotating machinery affects fatigue resistance. Systems exposed to continuous oscillation require compensators with reinforced layers and thicker walls. Poor installation practices—such as twisting, pre-stretching, misalignment, or over-compression—are also major contributors to premature failure.

Environmental factors such as UV exposure, salt spray (marine environment), and ozone concentration can accelerate degradation if the rubber type is not suitable. Routine inspection for cracks, bulging, surface hardening, or deformation is essential. In critical systems, inspections every 6 months are recommended.

Choosing the correct rubber material, ensuring proper installation, reducing unnecessary vibration load, and performing regular maintenance can significantly extend the compensator’s life and ensure long-term stability and safety for pipeline, automotive, and marine applications.

Customization Options for Flanges and Single Bellow

| Option | Flange Material | Flange Standards | Sphere (Bellow) Material |

|---|---|---|---|

| 1 | Cast Iron | ANSI (American National) | NR (Natural Rubber) |

| 2 | Carbon Steel | DIN (German Standards) | NBR (Nitrile Butadiene Rubber) |

| 3 | Stainless Steel | JIS (Japanese Standards) | EPDM |

| 4 | Brass | BS (British Standard) | CR (Chloroprene) |

| 5 | Aluminum Alloy | Chemical Industry Standards | FKM (Fluoroelastomer) |

| 6 | PVC | Marine Standards | Silicone |

| 7 | Other Materials | Custom Non-Standard | PTFE Lining |

Structure of Rubber Expansion Joint

Displacement Mode Diagram of Rubber Expansion Joints

Installation Diagram of SAE Rubber Compensator