Double-Wave Winding Rubber Expansion Joint

Flexible Design. Stable Performance.

Double-Wave Winding Rubber Expansion Joint - Product Introduction

The Double-Wave Winding Rubber Expansion Joint is a premium solution designed to ensure the safety, reliability, and longevity of your piping systems. Its innovative double-wave winding structure provides superior flexibility and high pressure resistance, allowing it to efficiently absorb vibration, compensate for thermal expansion, and reduce mechanical stress in industrial pipelines.

Ideal for water supply networks, HVAC systems, chemical processing plants, and various industrial pipelines, this expansion joint not only protects equipment from vibration and noise but also helps prevent pipeline fatigue and leakage. Its robust design accommodates axial, lateral, and angular movements, making it suitable for complex or high-stress installations.

Engineered for easy installation and low maintenance, the double-wave winding rubber expansion joint is a practical and cost-effective choice for engineers and facility managers. It ensures long-term vibration isolation, shock absorption, and misalignment compensation, improving system stability and extending the lifespan of both pipelines and connected machinery.

Choose this expansion joint for a reliable, durable, and high-performance solution that meets the demands of modern industrial piping systems.

Applications:

Industrial water pipelines

HVAC systems

Chemical and process plants

General industrial piping requiring vibration isolation and thermal compensation

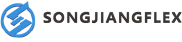

Double-Wave Winding Rubber Expansion Joint – Product Photo

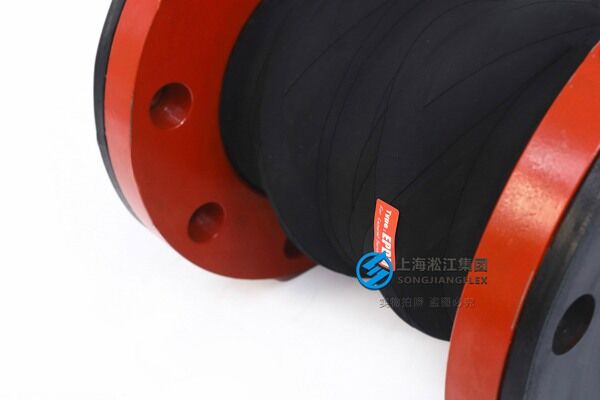

The Double-Wave Winding Rubber Expansion Joint is a specially engineered flexible connector designed for industrial and municipal piping systems. Its core component is a rubber body shaped into a double-wave corrugated structure and reinforced with multiple winding layers, which provides both flexibility and strength. The primary function of the expansion joint is to compensate for axial, lateral, and angular movements in pipelines caused by thermal expansion, contraction, or mechanical forces, thereby reducing stress and preventing damage to connected equipment.

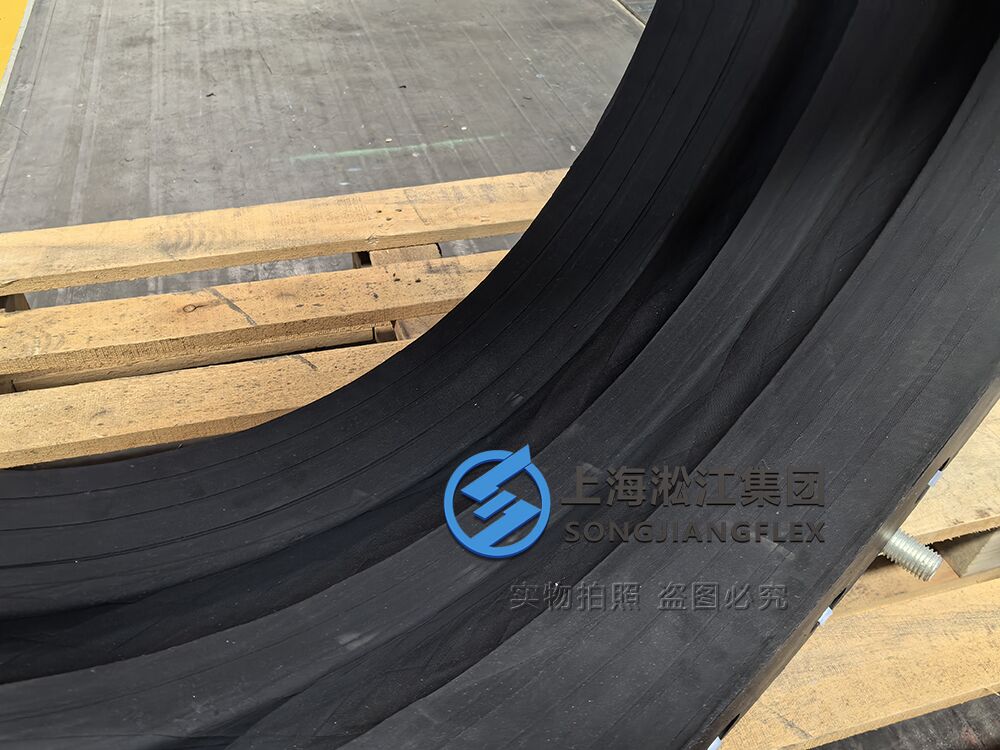

The double-wave design ensures that the joint can flex in multiple directions simultaneously, distributing stress evenly along the rubber body and the reinforced winding layers. The rubber material itself absorbs vibrations generated by pumps, compressors, fans, and other rotating machinery, while the winding reinforcement ensures the joint maintains high pressure resistance and structural integrity under dynamic loads. By combining elasticity with mechanical reinforcement, the joint effectively isolates vibration, reduces transmitted noise, and minimizes fatigue in metal piping, extending the service life of both the pipeline and connected equipment.

In addition, the expansion joint provides a hermetic seal, preventing leaks under varying pressures and temperatures. Its flexible structure also allows for slight misalignment in pipelines without imposing excessive stress on flanges or connections. The versatility of materials—such as EPDM for water systems, NBR for oil and fuel, or Hypalon for chemical resistance—enables its application across diverse industries, including HVAC, water treatment, chemical processing, and power generation. This combination of vibration isolation, movement compensation, pressure handling, and chemical compatibility makes the double-wave winding rubber expansion joint a critical component for maintaining the safety, reliability, and longevity of industrial piping systems.

The performance and durability of a Double-Wave Winding Rubber Expansion Joint are highly dependent on the materials used in its construction. The joint typically consists of three major components: the inner rubber tube, the external winding reinforcement, and the flange connections.

The inner tube is the primary barrier between the pipeline medium and the structural reinforcement. Common materials include EPDM (ethylene propylene diene monomer rubber), NBR (nitrile butadiene rubber), and Hypalon (CSM, chlorosulfonated polyethylene). EPDM is widely used for water, steam, and non-oil-based fluids due to its excellent resistance to heat, aging, and ozone. NBR is preferred for oil, fuel, and petroleum-based applications due to its chemical resistance, while Hypalon is used in highly corrosive or chemical-intensive systems for its superior chemical stability. Choosing the right inner rubber ensures the expansion joint maintains its flexibility and chemical compatibility throughout its service life.

The winding reinforcement is typically composed of high-strength textile cords or fiber layers, which are helically wound around the rubber body. This reinforcement enhances the joint’s pressure resistance and prevents excessive deformation under load, while still allowing the rubber to flex. The winding layers distribute stress evenly and prevent local overstretching, which is critical for applications involving high pressure or frequent thermal cycling.

The flanges are usually made from carbon steel or stainless steel, compliant with international standards such as ANSI, DIN, or JIS. Flanges provide a secure mechanical connection to pipelines and must be compatible with the system’s design pressure and temperature. Correct flange material selection is essential to prevent galvanic corrosion or mechanical failure, especially in chemically aggressive or high-temperature environments.

The combination of elastic rubber, reinforced winding, and high-quality flanges ensures that the double-wave winding rubber expansion joint delivers exceptional performance in absorbing vibration, compensating for movement, handling pressure, and resisting chemical attack. By carefully selecting the materials, engineers can tailor the expansion joint for each industrial application, achieving optimal safety, reliability, and longevity in pipeline systems.

The Double-Wave Winding Rubber Expansion Joint is specifically engineered to accommodate multiple types of pipeline movement and mechanical vibration, making it indispensable in industrial systems. The primary movements it compensates for include:

Axial movement: This is movement along the length of the pipeline caused by thermal expansion or contraction, pressure changes, or equipment-induced forces. The double-wave structure allows the rubber body to compress or extend, absorbing energy without stressing the flanges or pipeline.

Lateral movement: Horizontal or side-to-side displacement of the pipeline can occur due to settling, seismic activity, or mechanical misalignment. The elasticity of the rubber combined with the reinforced winding allows for lateral flexing without compromising the integrity of the connection.

Angular deflection: Pipelines may not always align perfectly; slight angular deviations are inevitable due to installation tolerances or operational shifts. The expansion joint can pivot at the connection point, accommodating angular misalignment and preventing stress concentration.

Vibration absorption: Industrial equipment such as pumps, compressors, fans, and turbines generate significant mechanical vibrations. The double-wave corrugated design, along with elastic rubber and winding reinforcement, dissipates vibration energy, reducing the transmission to connected piping and equipment. This prevents fatigue, reduces noise, and enhances overall system stability.

Shock and pulsation damping: Sudden pressure surges or pulsations in pipelines can damage joints, valves, and pumps. The expansion joint acts as a shock absorber, smoothing pressure fluctuations and protecting the system from transient forces.

By combining these capabilities, the double-wave winding rubber expansion joint ensures the safe, stable, and efficient operation of complex pipeline systems, particularly in demanding applications such as chemical plants, HVAC systems, water treatment, and industrial manufacturing. Its ability to handle multi-directional movement, vibration, and shock simultaneously makes it superior to rigid piping solutions and single-bellows designs.

Proper installation and maintenance are critical for the performance and longevity of a Double-Wave Winding Rubber Expansion Joint. Installation begins with correct alignment of flanges; misaligned flanges can introduce torsional stress, causing premature failure. Bolts should be tightened evenly in a star pattern to the recommended torque to avoid uneven compression of the rubber.

Supports and guides should be used along the pipeline to prevent excessive axial or lateral movement that exceeds the joint’s design limits. The rubber body should not be twisted or over-extended, as this can damage the internal fibers and compromise pressure resistance. Sharp edges or abrasive surfaces must be avoided during installation to prevent cuts or wear on the rubber surface.

Routine inspection is recommended to monitor for signs of wear, chemical degradation, or external damage. Any oil leaks, cracking, or unusual deformation should be addressed immediately. Cleaning the outer surface and checking flange bolts for tightness at regular intervals helps maintain structural integrity. In systems with aggressive media, the correct rubber material must be confirmed periodically to ensure chemical compatibility.

Maintenance practices should include documenting operating pressure, temperature, and movement cycles. This allows engineers to predict service life and schedule replacements before failure occurs. With proper installation and regular maintenance, the expansion joint can maintain vibration isolation, movement compensation, and pressure handling capabilities for many years, typically 5–15 years depending on operating conditions.

The Double-Wave Winding Rubber Expansion Joint offers several advantages that make it a preferred choice for industrial pipelines:

Excellent vibration and shock absorption: The double-wave structure combined with elastic rubber and winding reinforcement isolates mechanical vibrations from pumps, compressors, and rotating machinery, preventing fatigue and damage to connected equipment.

Multi-directional movement compensation: Axial, lateral, and angular movements are absorbed efficiently, protecting pipelines from thermal expansion, contraction, and misalignment.

High pressure and chemical resistance: The reinforced winding layers provide structural integrity under high-pressure conditions, while material selection (EPDM, NBR, Hypalon) ensures chemical and temperature compatibility.

Ease of installation and maintenance: Lightweight and flexible, the expansion joint can be installed without complex tools or procedures and requires minimal ongoing maintenance.

Versatile industrial applications: Commonly used in HVAC systems, water treatment plants, chemical and petrochemical industries, power generation, and general industrial manufacturing, the joint is suitable for systems requiring vibration isolation, noise reduction, and movement compensation.

Overall, its combination of flexibility, durability, and vibration isolation makes the double-wave winding rubber expansion joint an essential component in modern piping systems, ensuring safety, reliability, and extended service life across a wide range of industrial applications.

Customization Options for Flanges and Single Bellow

| Option | Flange Material | Flange Standards | Sphere (Bellow) Material |

|---|---|---|---|

| 1 | Cast Iron | ANSI (American National) | NR (Natural Rubber) |

| 2 | Carbon Steel | DIN (German Standards) | NBR (Nitrile Butadiene Rubber) |

| 3 | Stainless Steel | JIS (Japanese Standards) | EPDM |

| 4 | Brass | BS (British Standard) | CR (Chloroprene) |

| 5 | Aluminum Alloy | Chemical Industry Standards | FKM (Fluoroelastomer) |

| 6 | PVC | Marine Standards | Silicone |

| 7 | Other Materials | Custom Non-Standard | PTFE Lining |

Daily Production Showcase from Factory

Advantages of Double-Wave Winding Rubber Expansion Joint

The Double-Wave Winding Rubber Expansion Joint offers multiple advantages for industrial piping systems:

Excellent Vibration and Shock Absorption – The double-wave structure effectively isolates vibration and reduces noise, protecting pipelines and connected equipment.

Flexible Compensation for Movement – It accommodates axial, lateral, and angular movements, ensuring reliable operation under thermal expansion or pipeline misalignment.

High Pressure and Durability – Reinforced winding design provides strong resistance to internal pressure and long-term wear, extending service life.

Easy Installation and Maintenance – Lightweight and flexible, it can be installed without complex procedures and requires minimal maintenance.

Wide Industrial Applications – Suitable for water supply, HVAC, chemical, and other industrial pipelines where vibration control and movement compensation are critical.