Hand-wrapped Rubber Expansion Joint

Durability and Flexibility: The Advantages of Hand-Wrapped Rubber Expansion Joints

Hand-wrapped rubber expansion joint

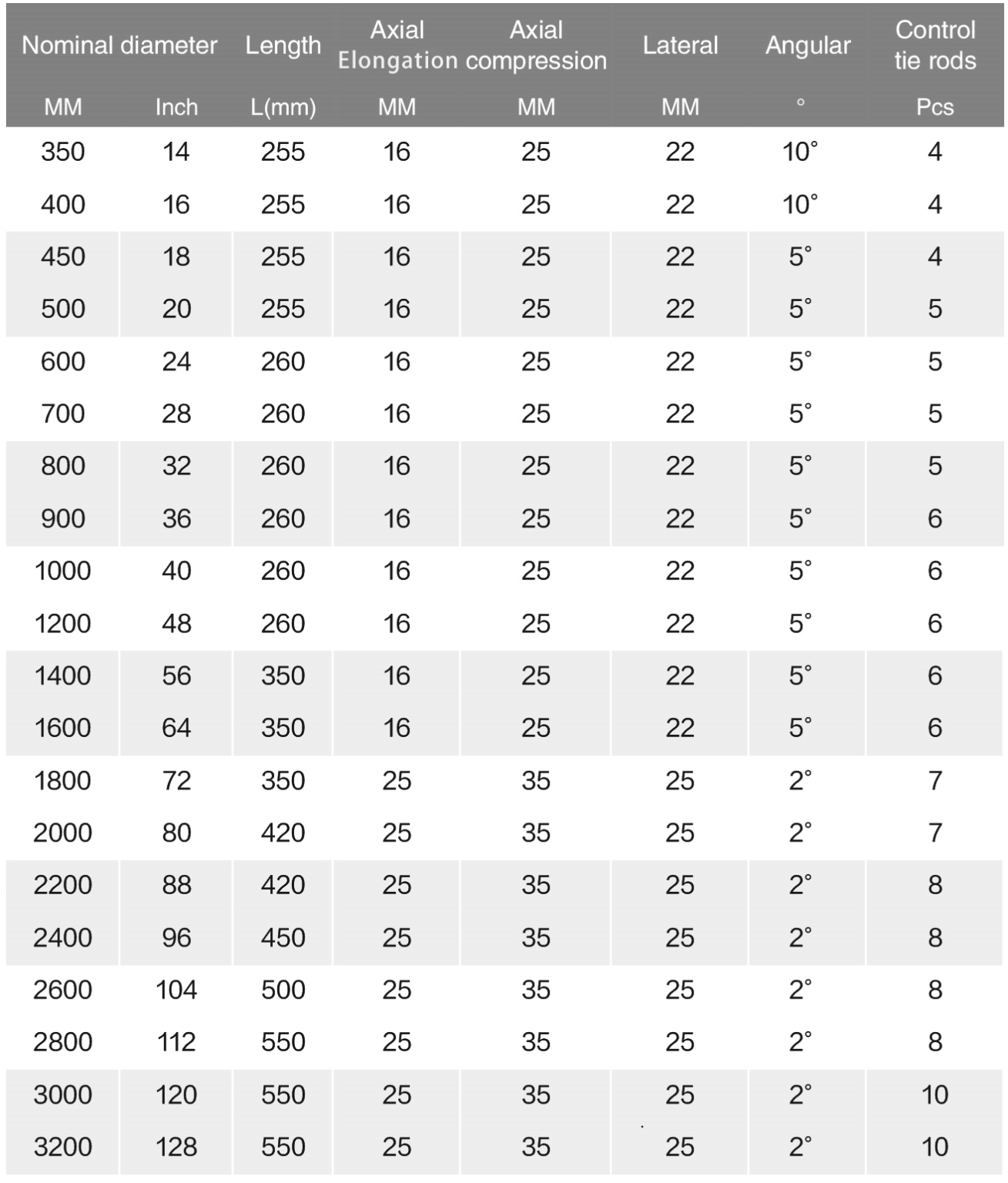

Hand-wrapped rubber expansion joints are designed to perform reliably under a wide range of operating conditions. Typically, these expansion joints can withstand a temperature range of -30°C to +120°C, making them suitable for most conventional piping systems. However, for more extreme applications, we offer specially designed joints that can handle higher temperatures and pressures. For instance, using high-temperature resistant materials like fluoropolymers or fluororubber linings, these joints can endure temperatures up to +200°C or even higher.

Regarding pressure, hand-wrapped rubber expansion joints are generally rated for working pressures between 10 to 25 bar. For applications in extremely high-pressure environments, such as oil and gas extraction or chemical plants, we can customize expansion joints to handle pressures exceeding 40 bar, ensuring reliable performance even under demanding conditions.

Whether in high-pressure steam systems, chemical processing environments, or extreme temperature conditions, hand-wrapped rubber expansion joints provide a trusted solution to maintain operational stability in your piping systems.

The service life of hand-wrapped rubber expansion joints depends on several factors, including the operating environment, material selection, and maintenance practices. With proper installation and regular maintenance, these joints typically provide reliable service for 10 to 15 years. They significantly extend the lifespan of the pipeline system, reducing the need for costly repairs and minimizing downtime.

Under normal operating conditions, if the expansion joints are installed according to best practices and regularly checked for wear and tear, they can endure for over a decade. If high-performance materials such as fluoropolymers or EPDM are used, the longevity can be extended further, especially in challenging environments.

It is essential to note that the lifespan of the expansion joint can be affected by factors like high temperatures, extreme pressures, and aggressive chemical exposure. In such cases, more frequent inspections and timely replacements may be required to ensure the continuous reliability of the system.

Installing hand-wrapped rubber expansion joints is relatively straightforward, but it is critical to follow specific guidelines to ensure optimal performance. The first step is to ensure that the expansion joint flanges are properly aligned with the pipeline. This prevents misalignment and additional strain on the joint during installation. The joint should not be overstretched or compressed, as maintaining its natural shape and flexibility is crucial for effective movement absorption.

Each expansion joint comes with a detailed installation manual, providing step-by-step instructions on correct installation, flange attachment, and ensuring tight sealing. These instructions are designed to facilitate proper installation and minimize the risk of operational issues.

For complex systems or applications requiring extreme operating conditions, it is advisable to consult professional installers who can ensure the expansion joints are integrated into the pipeline system correctly, ensuring long-term performance and system reliability.

Yes, hand-wrapped rubber expansion joints are highly resistant to a variety of chemicals, oils, acids, and solvents, depending on the material used. The rubber materials selected for these joints are known for their excellent chemical resistance, making them ideal for environments that come into contact with aggressive chemicals or harsh substances.

For highly corrosive applications, such as those found in chemical processing, we offer specialized rubber compounds such as fluoropolymer linings or EPDM. These materials provide enhanced resistance to a wide range of chemicals, including strong acids, alkalis, and solvents, ensuring the longevity of the expansion joint in harsh environments.

It is important to note that the chemical resistance of the expansion joint can vary based on the type of chemical, its concentration, and the exposure duration. In particularly aggressive environments, it is recommended to select a more chemically resistant material to maximize the performance and lifespan of the joint. Regular inspections are also essential to identify any early signs of degradation caused by chemical exposure.

Indeed, one of the standout features of hand-wrapped rubber expansion joints is their ability to absorb and isolate vibrations, making them ideal for high-vibration environments. These joints are especially effective in applications like compressors, pumps, and engines, where vibrations can cause significant wear and stress on piping systems.

The flexible design of hand-wrapped rubber expansion joints allows them to effectively reduce mechanical vibrations, ensuring smooth and stable operation of equipment. This vibration isolation capability helps prevent damage to sensitive components and minimizes the risk of fatigue-related failure in the system.

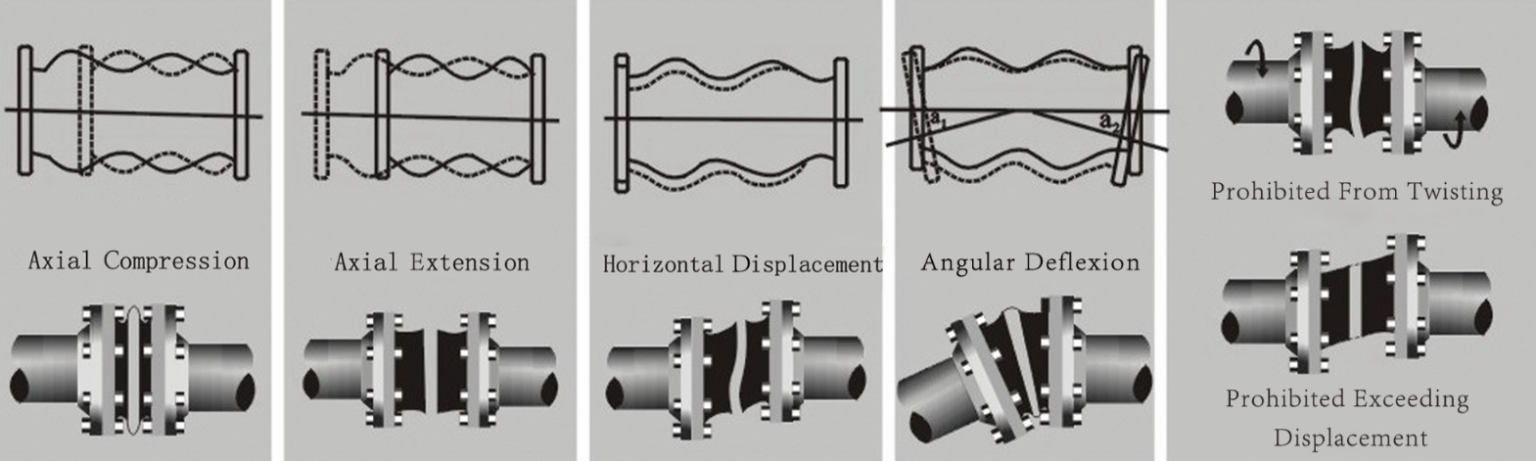

Moreover, the flexibility of these joints allows them to accommodate axial, lateral, and angular movements, making them an ideal solution for systems that experience both vibration and thermal expansion. This ensures that the system operates more efficiently, reducing the chances of unexpected downtime or costly repairs.

Customization Options for Flanges and Single Bellow

| Option | Flange Material | Flange Standards | Sphere (Bellow) Material |

|---|---|---|---|

| 1 | Cast Iron | ANSI (American National) | NR (Natural Rubber) |

| 2 | Carbon Steel | DIN (German Standards) | NBR (Nitrile Butadiene Rubber) |

| 3 | Stainless Steel | JIS (Japanese Standards) | EPDM |

| 4 | Brass | BS (British Standard) | CR (Chloroprene) |

| 5 | Aluminum Alloy | Chemical Industry Standards | FKM (Fluoroelastomer) |

| 6 | PVC | Marine Standards | Silicone |

| 7 | Other Materials | Custom Non-Standard | PTFE Lining |

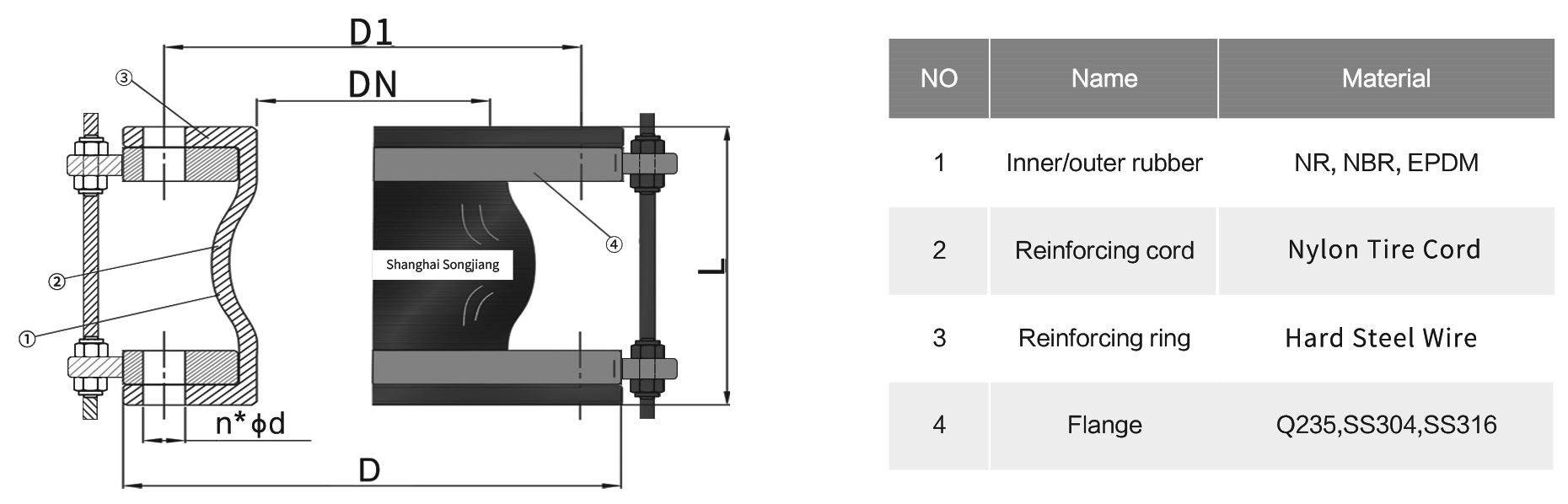

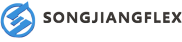

Structure of Rubber Expansion Joint

Displacement Mode Diagram of Rubber Expansion Joints

Installation Diagram of Hand-wrapped rubber expansion joint