Double Sphere Rubber Expansion Joint

High-Performance Rubber Expansion for Industrial Excellence

Double Sphere Rubber Expansion Joint

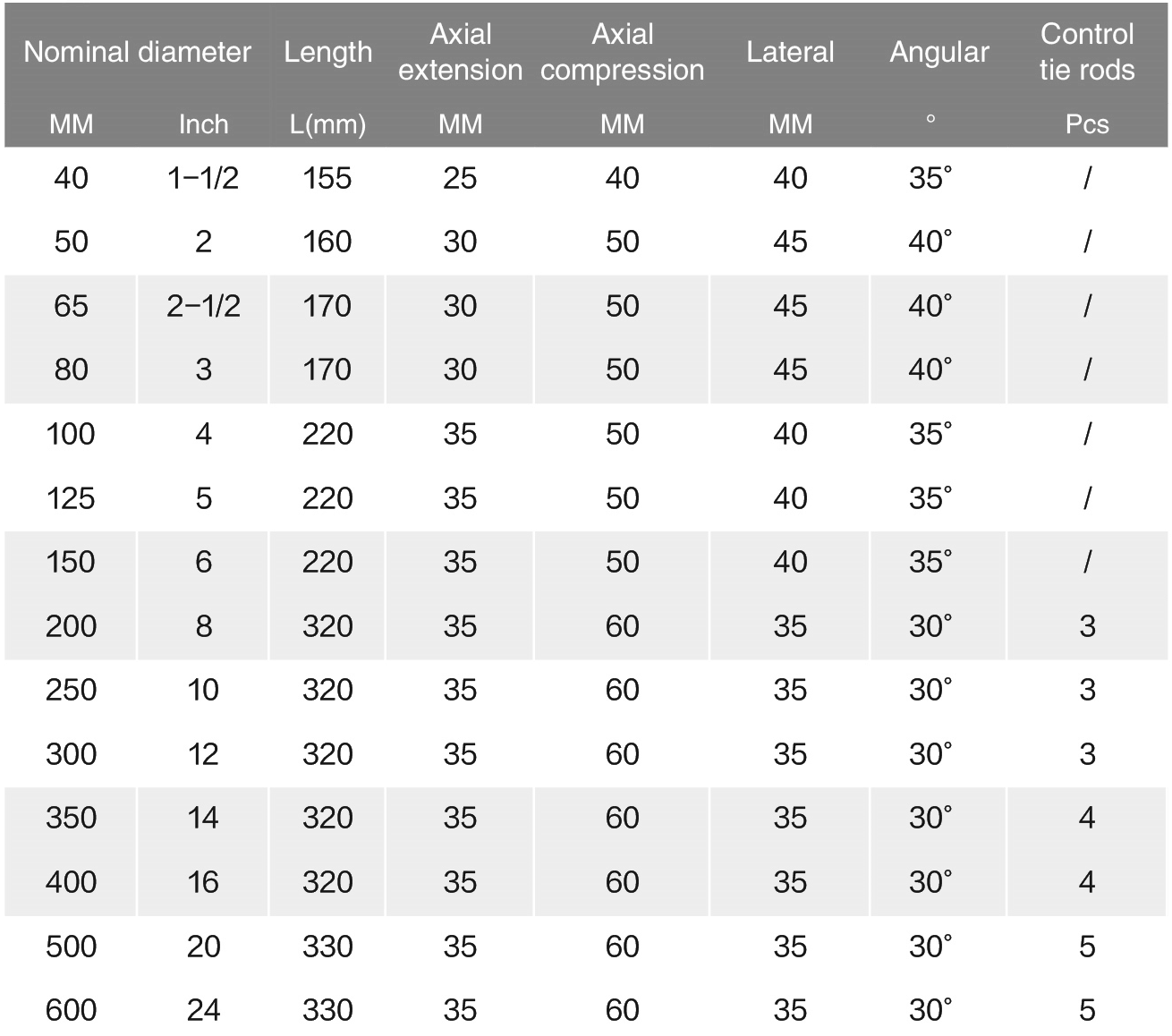

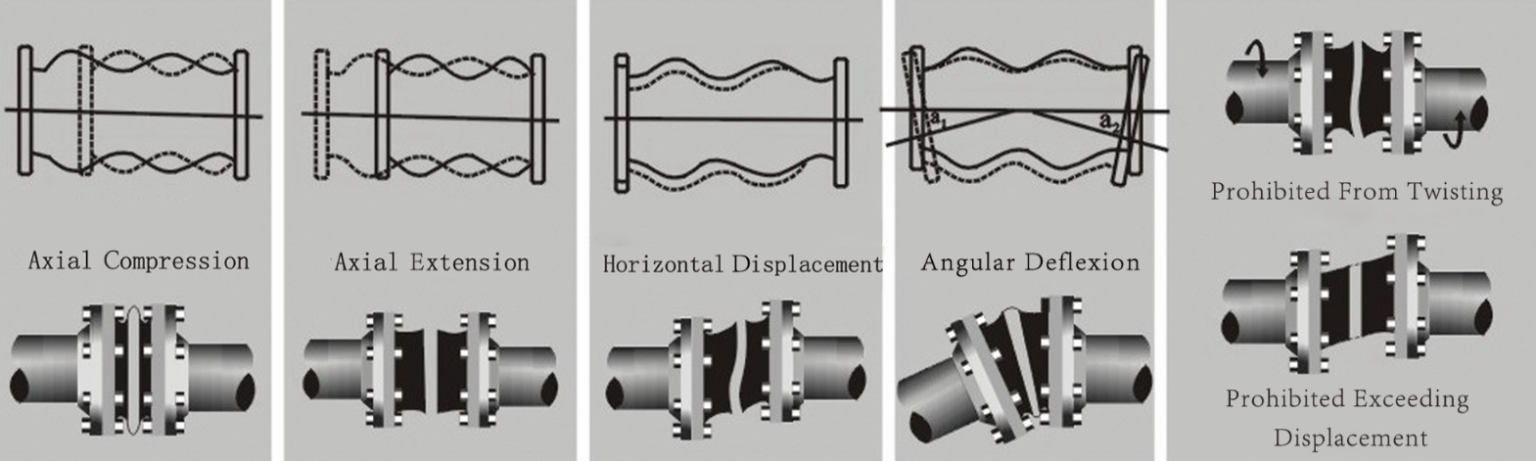

The double-sphere rubber expansion joint offers significant improvements in flexibility and movement compensation over single-sphere or conventional bellows designs. The unique dual-sphere geometry allows the joint to accommodate larger axial, lateral, and angular movements without overstressing the rubber material. By distributing stress more evenly across the bellows, the double-sphere design minimizes stress concentration points, which are common failure areas in single-sphere or standard bellows. This leads to a longer fatigue life for the entire piping system, making it particularly suitable for applications involving high dynamic loads, fluctuating pressures, or complex pipeline layouts. Moreover, the double-sphere structure reduces the risk of permanent deformation or buckling under repeated thermal expansion and contraction cycles, ensuring consistent performance over the joint’s operational life. In heavy-duty industrial installations such as power plants, petrochemical facilities, and marine pipelines, this enhanced durability is critical for maintaining system integrity and reducing maintenance costs.

The performance of a rubber expansion joint is highly dependent on the type of elastomer used for the bellows. Materials such as EPDM, NBR (nitrile), and neoprene each provide distinct mechanical and chemical properties that determine the joint’s suitability for specific industrial environments. EPDM offers excellent resistance to heat, weathering, and oxidative degradation, making it ideal for high-temperature and outdoor applications. NBR provides superior resistance to oils, fuels, and certain chemicals, making it suitable for petrochemical pipelines. Neoprene offers a balanced combination of chemical resistance, flexibility, and moderate temperature tolerance. The selection of an appropriate rubber material ensures that the expansion joint maintains its flexibility, pressure tolerance, and chemical resistance over time. Mismatched materials can lead to accelerated aging, cracking, or failure under thermal or chemical stress, potentially compromising the entire pipeline system. Therefore, careful material selection based on operating temperature, chemical exposure, and mechanical load is critical for reliable long-term performance.

The pressure rating and expected service life of a double-sphere rubber expansion joint are calculated using a combination of mechanical design parameters and operational conditions. The joint’s maximum pressure capacity depends on the pipe diameter, bellows thickness, number of convolutions, and flange rigidity. Service life is typically estimated using fatigue analysis, which considers the number of movement cycles, magnitude of axial/lateral/ angular displacement, and operating pressure fluctuations. Engineers may also use finite element analysis (FEA) to simulate stress distribution under various load scenarios, identifying potential weak points and optimizing the design to minimize failure risk. With proper installation and operation within specified limits, the expected service life of a well-designed double-sphere expansion joint can range from 5 to 10 years, depending on environmental conditions and load intensity.

Double-sphere rubber expansion joints are particularly effective in environments with high-frequency vibration or pulsating fluid flow. The multi-layered flexible structure of the joint allows it to absorb and dampen both axial and lateral vibrations, significantly reducing dynamic stress on connected piping and equipment. In systems with pumps, compressors, or valves generating pulsating forces, the expansion joint acts as a shock absorber, smoothing out pressure fluctuations and mitigating water hammer effects. This not only protects sensitive equipment but also reduces fatigue in the pipeline material, minimizing maintenance requirements and preventing unexpected downtime in critical industrial operations.

Selecting the correct expansion joint for a piping system requires comprehensive evaluation of multiple factors, including pipe diameter, operating pressure, temperature, fluid type, expected axial/lateral/ angular movements, installation length, and flange standards. Engineers typically perform calculations based on fluid dynamics and thermal expansion to determine the required displacement capacity. Additional considerations, such as vibration frequency, weight of supported equipment, and environmental conditions, may also influence the selection. The goal is to ensure that the expansion joint provides sufficient flexibility and stress relief while maintaining mechanical integrity and system reliability.

Customization Options for Flanges and Single Bellow

| Option | Flange Material | Flange Standards | Sphere (Bellow) Material |

|---|---|---|---|

| 1 | Cast Iron | ANSI (American National) | NR (Natural Rubber) |

| 2 | Carbon Steel | DIN (German Standards) | NBR (Nitrile Butadiene Rubber) |

| 3 | Stainless Steel | JIS (Japanese Standards) | EPDM |

| 4 | Brass | BS (British Standard) | CR (Chloroprene) |

| 5 | Aluminum Alloy | Chemical Industry Standards | FKM (Fluoroelastomer) |

| 6 | PVC | Marine Standards | Silicone |

| 7 | Other Materials | Custom Non-Standard | PTFE Lining |

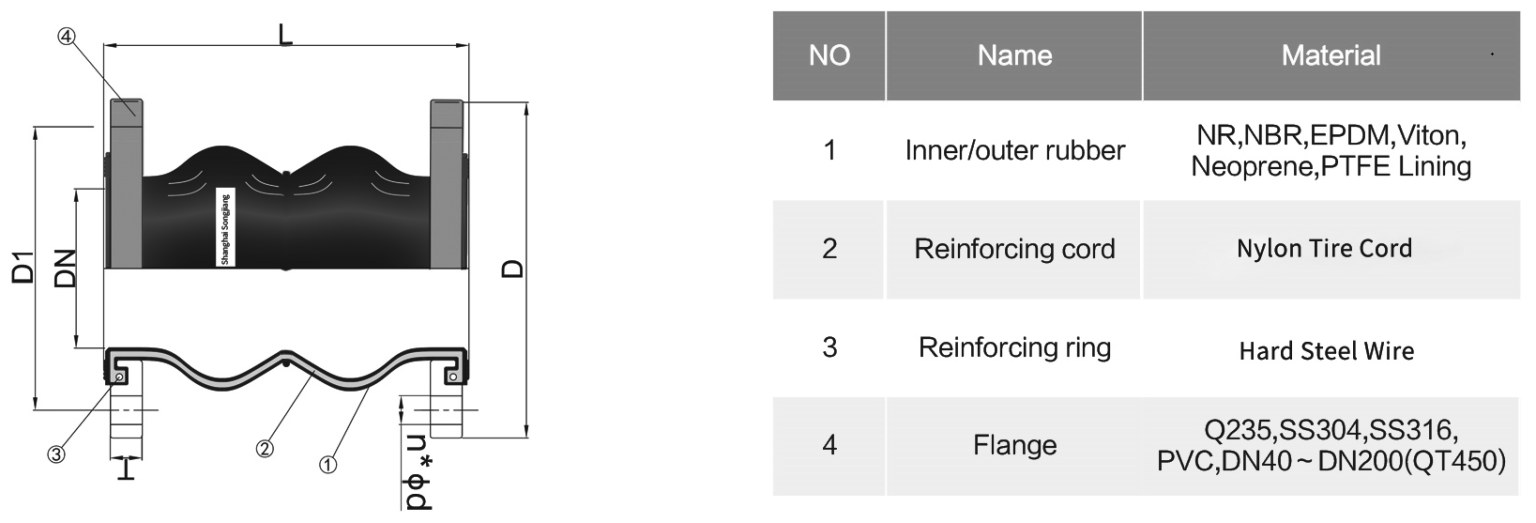

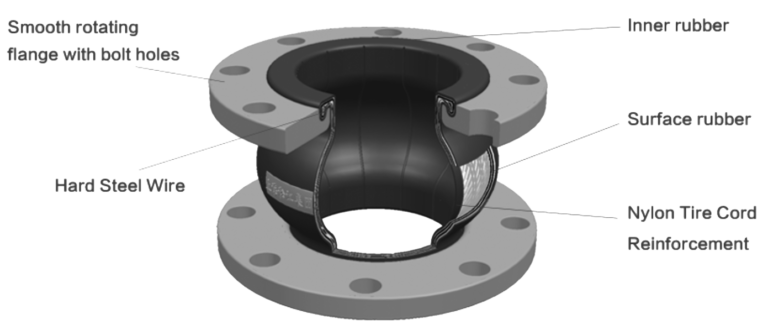

Structure of Rubber Expansion Joint

Displacement Mode Diagram of Rubber Expansion Joints

Installation Diagram of Double Sphere Rubber Expansion Joint