Rubber Expansion Joint

Expertly Crafted Rubber Shear Mounts, Ensuring Stability and Durability

Our products

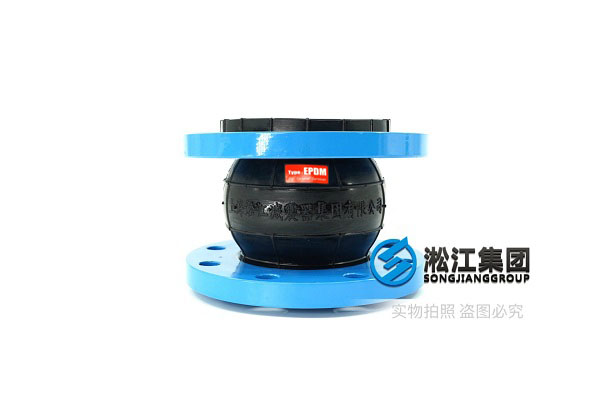

Rubber Expansion Joint

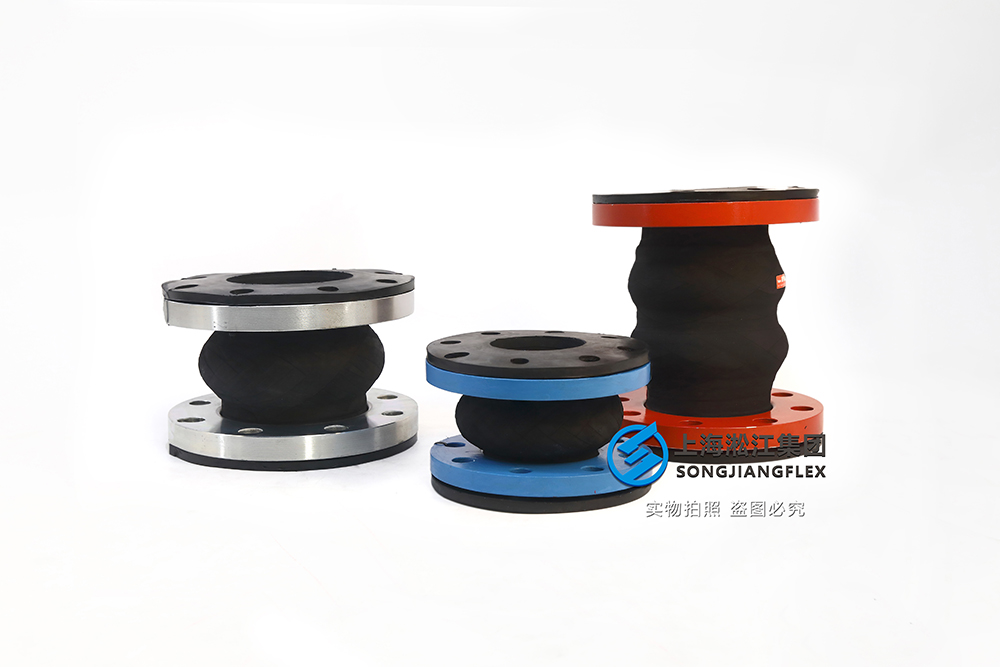

Product Showcase

Reliable Rubber Expansion Joints You Can Trust

Rubber Expansion Joint

Rubber Expansion Joint

Rubber Expansion Joint

Rubber Expansion Joint

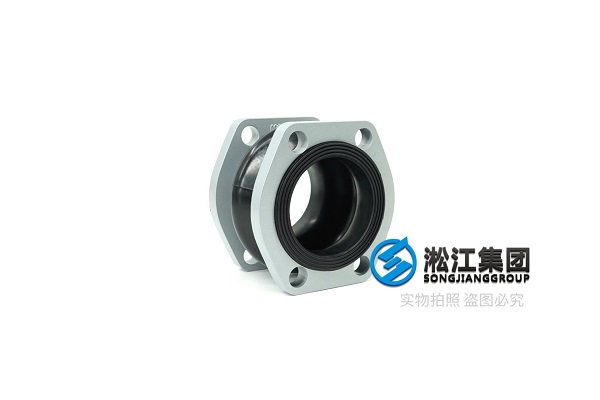

Rubber Bellows

Customizable

Why Choose Us

Trusted Rubber Expansion Joint Manufacturer with 30 Years of Expertise

Factory-direct solutions with natural rubber, customizable options, reliable quality, and trusted performance.

We own and operate our factory, ensuring strict quality control, stable lead times, and support for small-batch customization

With over three decades in vibration isolation, we offer trusted solutions backed by rich technical knowledge and real-world application.

Our isolators use pure natural rubber for excellent elasticity, durability, and superior shock absorption compared to synthetic materials.

Our ISO-compliant production lines and testing systems ensure consistent quality and reliable performance across all batches.

+86 13032112360

Common Questions

Most Popular Questions

Rubber expansion joints are flexible components used to connect pipes, consisting of a rubber body, internal reinforcement with steel wire or bands, strengthening layers, and an outer protective layer. The working principle of a rubber expansion joint is based on the elasticity and compressibility of rubber materials. It can absorb the displacement caused by temperature fluctuations, pressure changes, or seismic activity in the pipeline, preventing stress from building up in the system and reducing the potential for damage.

These joints function not only as seals but also provide vibration isolation, noise reduction, and stress compensation. They can adapt to changes in pipe alignment, helping to reduce the impact of thermal expansion, vibration, and settling in various industrial systems.

The combination of these features makes rubber expansion joints crucial for maintaining the long-term stability and performance of pipelines, especially in industries such as petrochemical, power generation, water treatment, and HVAC.

Rubber expansion joints offer a wide range of advantages that make them a preferred choice in many industrial applications. One of their primary benefits is their exceptional elasticity and compressibility, which allow them to effectively compensate for temperature changes, mechanical vibrations, and other pipeline movements. This helps to reduce stress on the system and prevent damage.

Another significant advantage is their ability to isolate vibrations and reduce noise. In industries with heavy machinery or production lines, vibration can damage equipment and reduce comfort, but rubber expansion joints absorb these vibrations, protecting other parts of the system.

Rubber expansion joints also provide excellent corrosion resistance, making them ideal for use in chemical, food processing, and other industries where corrosive fluids are present. Compared to metal joints, they are easier to install, lighter, and more cost-effective.

Additionally, these joints are available in materials that can withstand both high temperatures and pressures, allowing them to function efficiently in harsh industrial environments.

Rubber expansion joints are widely used across various industries, particularly where temperature fluctuations, pressure changes, mechanical vibrations, and movement compensation are significant concerns. Some of the key application areas include:

Petrochemical Industry: In oil, gas, and chemical plants, rubber expansion joints are used to handle high-temperature, high-pressure, and corrosive environments, ensuring safe and efficient pipeline operation.

Power Generation: Power plants, especially thermal and nuclear plants, require rubber expansion joints to manage the thermal expansion, pressure fluctuations, and vibrations in piping systems, ensuring smooth and safe operations.

Water Treatment and Distribution: In water treatment and supply systems, rubber expansion joints compensate for changes in water pressure and temperature, maintaining the integrity of the piping system.

HVAC Systems: In heating, ventilation, and air conditioning systems, rubber expansion joints help reduce noise and vibration, enhancing comfort and system performance.

Mining and Metallurgy: These joints are often used in mining and metallurgy industries to withstand high temperatures, corrosive environments, and heavy-duty applications, ensuring the pipeline system remains stable and operational.

Marine and Shipbuilding: In marine engineering and offshore platforms, rubber expansion joints handle the vibrations and displacements caused by seawater conditions, ensuring a durable and stable connection.

Choosing the right rubber expansion joint involves considering several factors to ensure optimal performance. Key considerations include:

Pipeline Medium: Select the appropriate rubber material based on the type of fluid or gas transported in the pipeline. For example, Neoprene or NBR (Nitrile Rubber) is ideal for chemical resistance, while EPDM or silicone rubber can handle high-temperature steam.

Operating Temperature and Pressure: The rubber expansion joint should be selected based on the operating temperature and pressure of the pipeline. For high-pressure systems, stronger materials and designs are required, while for high-temperature applications, materials like fluorocarbon or silicone should be considered.

Displacement Compensation Requirements: Consider the amount of movement expected in the system, as the rubber expansion joint must be able to absorb this movement without failure. The joint's flexibility and expansion range must match the system's displacement needs.

Installation Environment: The physical installation environment, including space constraints, temperature, humidity, and accessibility, should also be factored in when selecting the right model and size.

Rubber expansion joints’ ability to withstand high temperature and pressure is primarily dependent on the materials used and their structural design. High-temperature-resistant rubber materials such as silicone or fluorocarbon rubber are selected for their ability to maintain flexibility and sealing capabilities in high-heat environments.

The structural design further enhances pressure resistance. By reinforcing the rubber layers with high-strength steel wires, fabrics, or metal bands, the joint can distribute pressure more evenly, preventing local overloading and potential failure. Additionally, internal pressure balance designs help to manage pressure differentials, ensuring long-term stability and durability.

Rubber expansion joints also undergo rigorous testing to ensure they meet the required temperature and pressure ratings, guaranteeing their reliability in demanding industrial conditions.

Maintaining rubber expansion joints involves regular inspection, cleaning, and corrosion protection. Key maintenance practices include:

Visual Inspection: Check for any visible cracks, wear, or aging signs such as surface cracking or elasticity loss. Look for any deformation caused by excessive pressure or temperature.

Cleaning: Ensure that the joints are kept clean, especially the sealing surfaces, to prevent contaminants from affecting the seal. Accumulated dust or debris can degrade the sealing performance.

Corrosion Protection: In harsh environments, such as chemical or seawater exposure, apply protective coatings or select corrosion-resistant rubber materials to extend the lifespan of the expansion joint.

Regular Functional Checks: Test the joint’s flexibility and sealing performance during routine system inspections to ensure there are no leaks and that it can still absorb the expected displacement.

By following these maintenance procedures, the rubber expansion joints can operate effectively and last longer, ensuring the continued reliability of the system.

The sealing performance of rubber expansion joints is largely due to the material's inherent elasticity and compressibility, which allow the joints to create tight seals even under varying pressure conditions. Different rubber materials (e.g., NBR, EPDM, fluorocarbon) are selected based on the pipeline’s operating conditions, ensuring optimal sealing in various media.

The joint's design also plays a crucial role. Features such as internal reinforcement layers, properly designed flanges, and metal wire reinforcement help maintain the joint's structural integrity and prevent leakage under pressure. Additionally, optimized sealing geometry ensures a uniform compression around the sealing surface, improving the effectiveness of the seal.

Regular testing for seal integrity, including pressure and vacuum tests, ensures that the joints maintain their sealing properties under the expected operating conditions.

Rubber expansion joints can fail under certain conditions, typically due to:

Excessive Temperature: If exposed to temperatures beyond the rubber's rated capacity, the material can degrade, losing its flexibility and becoming brittle, leading to seal failure.

High Pressure: Operating pressure exceeding the joint’s design specifications can cause deformation, rupture, or leakage.

Chemical Exposure: Some aggressive chemicals can degrade rubber compounds, especially if the wrong type of rubber is used for a specific chemical medium.

Mechanical Damage: Physical impacts, such as those from rough handling or excessive vibration, can damage the joint, compromising its integrity and sealing ability.

To prevent failure, it is important to choose the correct material and size for the application, regularly inspect the joints, and ensure that they are used within their operational limits.

Rubber expansion joints are environmentally friendly in terms of their production and usage. Many manufacturers are now using recyclable rubber materials, which helps reduce resource waste. Additionally, because these joints are often used in industrial systems, they help mitigate energy loss by reducing vibration and noise, thus contributing to overall energy efficiency.

Moreover, rubber expansion joints prevent the leakage of hazardous substances, ensuring that they protect the environment from potential contamination. In industries that require the handling of toxic or corrosive fluids, rubber expansion joints help to maintain the integrity of the system and prevent environmental harm.

The quality of rubber expansion joints is ensured through stringent quality control measures throughout the manufacturing process. From selecting raw materials to the final testing, every stage is monitored for compliance with international standards.

Manufacturers use advanced equipment to ensure precise dimensions, strong adhesion, and high-quality rubber formulations. Each rubber expansion joint undergoes various tests, including pressure resistance, flexibility, high-temperature stability, and corrosion resistance tests, to ensure its performance in real-world conditions.

Strict quality assurance protocols and certifications (such as ISO 9001) also guarantee that the product will meet the necessary operational standards and specifications.

While rubber expansion joints are designed for long-term use, periodic replacement may be necessary, depending on their exposure to harsh conditions. Over time, factors like extreme temperature, pressure fluctuations, and chemical exposure can degrade the rubber material, reducing its elasticity and sealing performance.

Routine inspection is key to identifying signs of wear and tear, such as cracking, hardening, or loss of flexibility. If these issues arise, replacement should be considered to maintain the integrity of the entire system.

Rubber expansion joint technology continues to evolve with advancements in material science and design. Key future trends include:

Material Innovation: Development of new, more durable rubber compounds capable of withstanding higher temperatures, pressures, and aggressive chemicals.

Smart Technology: Integration of sensors and IoT technology to enable real-time monitoring of joint conditions, allowing for predictive maintenance and reducing system downtime.

Environmental Sustainability: Focus on using sustainable, recyclable materials in the production of rubber expansion joints, further reducing the environmental impact of industrial operations.

These innovations will expand the use of rubber expansion joints in more demanding applications and ensure they remain a critical component in modern industrial systems.