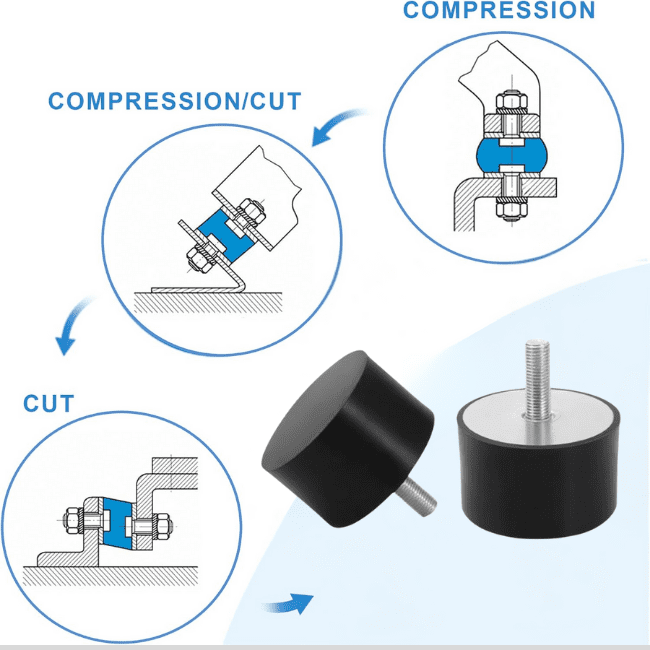

JNBE Type Cylindrical Mounts

Exceptional Care Provided by Highly Experienced Dental Professionals

JNBE Type Cylindrical Mounts

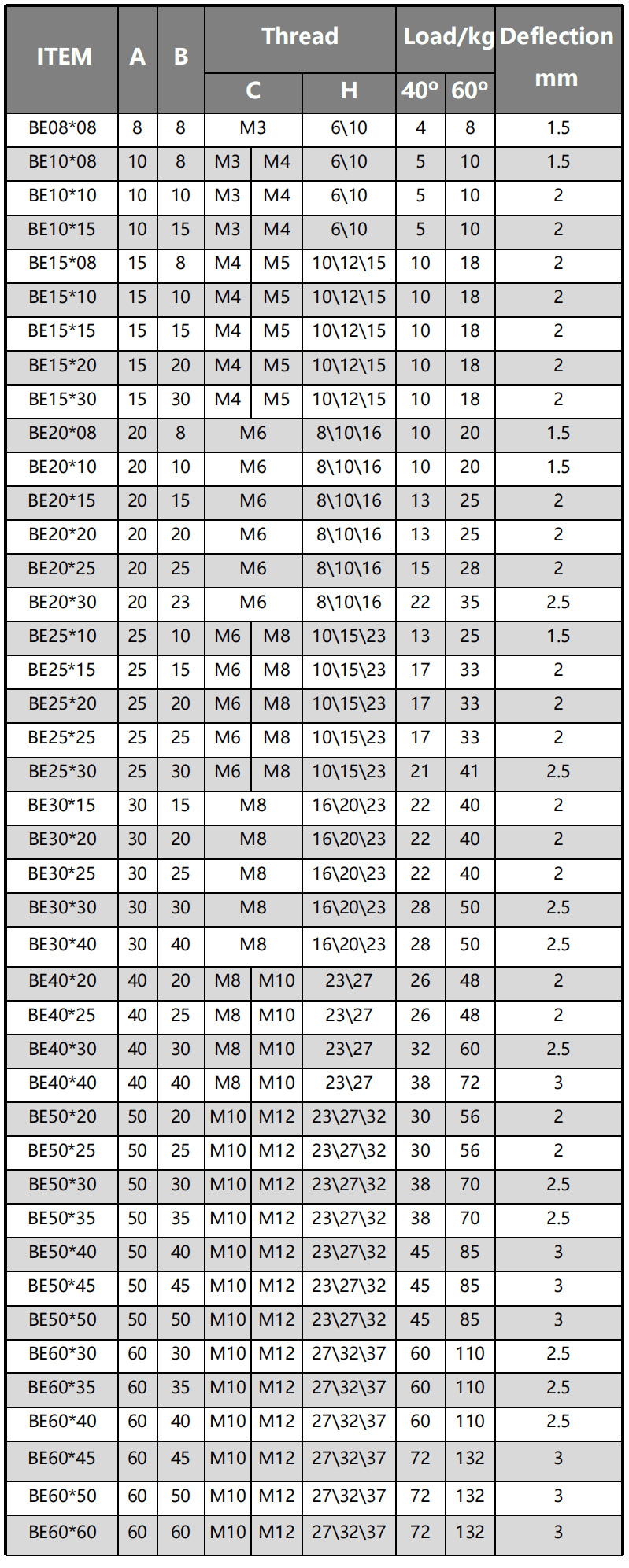

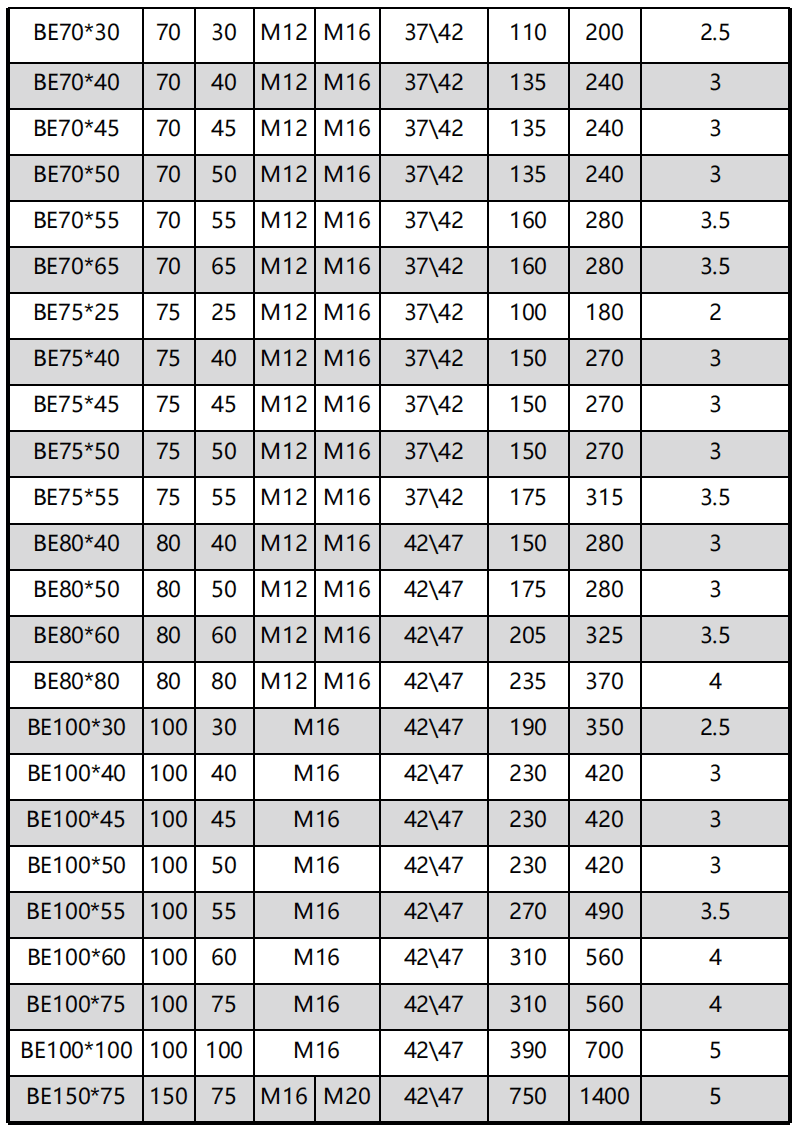

The load capacity of JNBE cylindrical mounts is a key technical parameter that determines their range of applications. It mainly depends on the size of the mount and the hardness of the rubber material. Typically, these mounts can support static loads ranging from several dozen to several hundred kilograms. Larger sizes and harder rubber compounds provide higher load-bearing capacity. However, when selecting a mount, it is important to consider not only the static weight of the equipment but also the dynamic loads generated during operation, such as vibration impacts and shock loads. Proper load matching ensures stable equipment operation and prevents premature failure or performance degradation of the mount. Our engineering team can provide detailed load calculations and model recommendations based on your equipment weight and operating conditions, helping you choose the most suitable vibration mount and extending the service life of both the equipment and the isolator.

The natural frequency of a vibration isolator is a crucial factor affecting its vibration reduction performance. The typical natural frequency range of JNBE cylindrical mounts is between 5Hz and 30Hz, influenced by rubber hardness and applied load during installation. A lower natural frequency generally means better isolation of low-frequency vibrations, which are common in rotating machinery such as pumps and compressors. Selecting a natural frequency that does not coincide with the equipment’s operating frequency is essential to avoid resonance, which can amplify vibrations instead of reducing them. Understanding your equipment’s vibration characteristics and choosing the appropriate natural frequency range is vital for designing an effective isolation system. We offer professional technical support to help you evaluate and match the best parameters to ensure system stability and reliability.

Rubber hardness is a key factor that affects the elasticity, load capacity, and vibration isolation performance of JNBE cylindrical mounts. It is usually expressed in Shore A hardness. Harder rubber (70-90 Shore A) offers higher load-bearing capacity and dimensional stability, suitable for heavier equipment where structural rigidity is important, but it provides relatively less vibration damping. Conversely, softer rubber (40-60 Shore A) has better elasticity and can absorb and cushion vibrations more effectively, especially low-frequency vibrations, but it has lower load capacity. When selecting rubber hardness, you should consider the weight of your equipment, vibration frequency, and desired level of vibration isolation. Environmental factors such as temperature, exposure to oils, or chemicals may also influence material choice. Our technical team can assist you in analyzing your specific working conditions and recommend the optimal hardness level to balance load capacity and vibration damping performance.

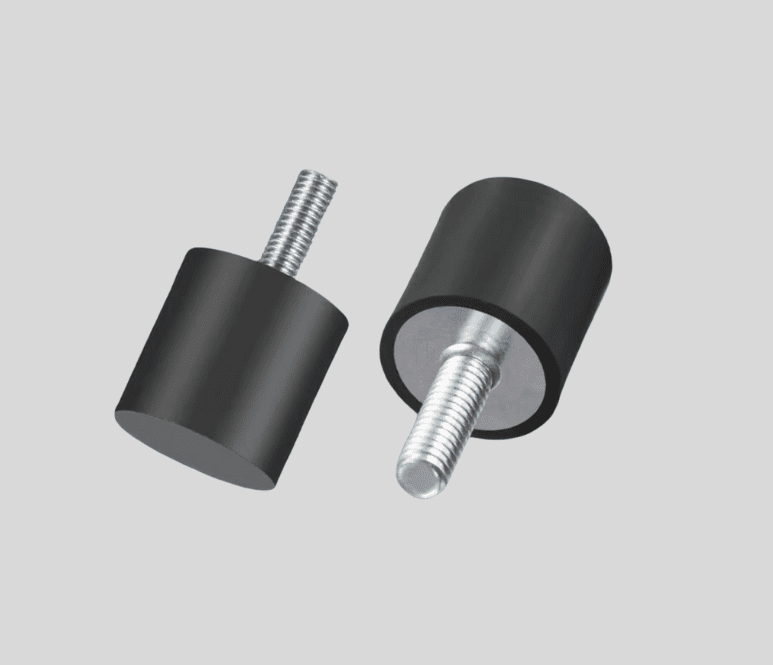

Installation diagram of JNBE Type Cylindrical Mounts:

Installation Diagram of JNBE Cylindrical Vibration Mount

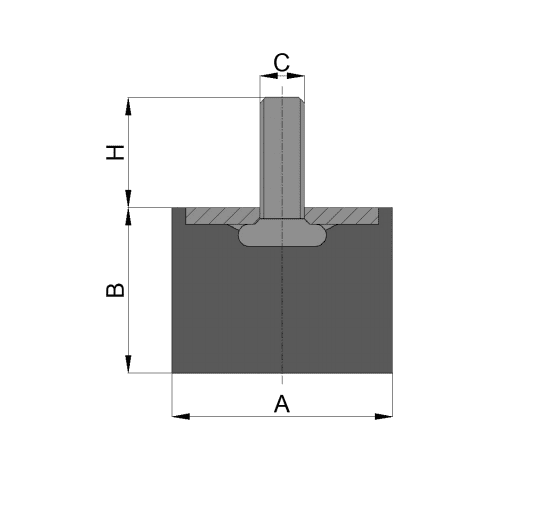

Parameter Table of JNBE Vibration mount

If you like this Cylindrical Vibration Mount but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]