GVV Type Cylindrical Mounts

Exceptional Care Provided by Highly Experienced Dental Professionals

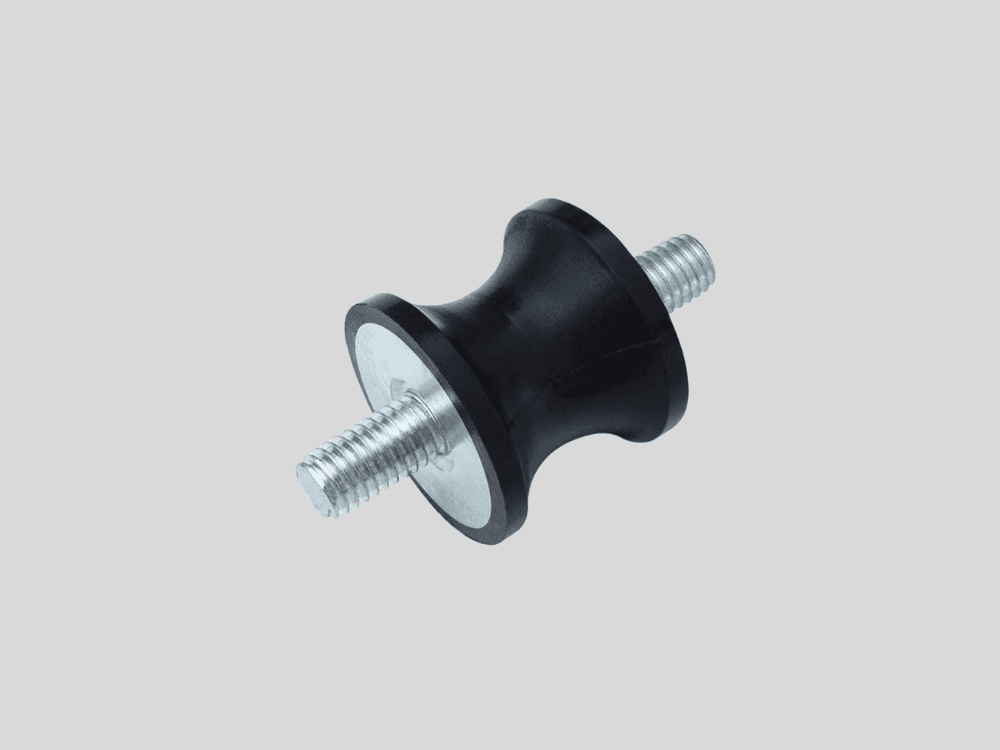

GVV Type Waisted Cylindrical Rubber Mounts

The waisted geometry reduces the cross-sectional stiffness of the rubber body in both axial and radial directions. As a result, the mount exhibits a lower natural frequency, which shifts the system’s isolation range to include more of the mid-frequency vibration spectrum—typically where most industrial equipment operates. Additionally, a lower natural frequency improves the overall transmissibility curve by allowing the ratio of transmitted force to input force to drop below 1.0 over a wider frequency band. This means that vibrations are significantly dampened before reaching the supporting structure. Such behavior is especially beneficial in HVAC systems, electric motors, and compressors, where reducing operational resonance is critical for performance, noise reduction, and equipment longevity.

Waisted cylindrical mounts outperform standard cylindrical designs in terms of fatigue resistance under repeated dynamic loads. The waisted rubber profile, with its hourglass-like curvature, promotes even distribution of internal stresses during operation. This helps prevent the formation of micro-cracks and reduces the likelihood of rubber tear or material fatigue over time. In contrast, straight cylindrical mounts tend to experience higher stress concentrations near the bonded interfaces, which can lead to premature failure. The superior fatigue behavior of waisted mounts makes them especially reliable in applications with continuous start-stop cycles or high vibration duty, such as air compressors, industrial pumps, or automated manufacturing lines.

Thread-end bonding is a critical element in ensuring the mount's structural integrity under high-frequency, high-amplitude vibration. In waisted cylindrical mounts, the male studs are typically vulcanized directly into the rubber using precision-controlled steel-to-elastomer bonding during molding. This creates a unified, chemically bonded interface that resists pull-out forces and rotational stresses. In environments exposed to temperature changes, oil contamination, or high humidity—such as marine platforms, automotive engine compartments, or heavy industrial machines—poor bonding can lead to stud detachment or loosening over time. High-quality bonding not only improves safety and reliability but also reduces maintenance frequency and replacement costs, making it an essential design parameter for long-term use in vibration-critical systems.

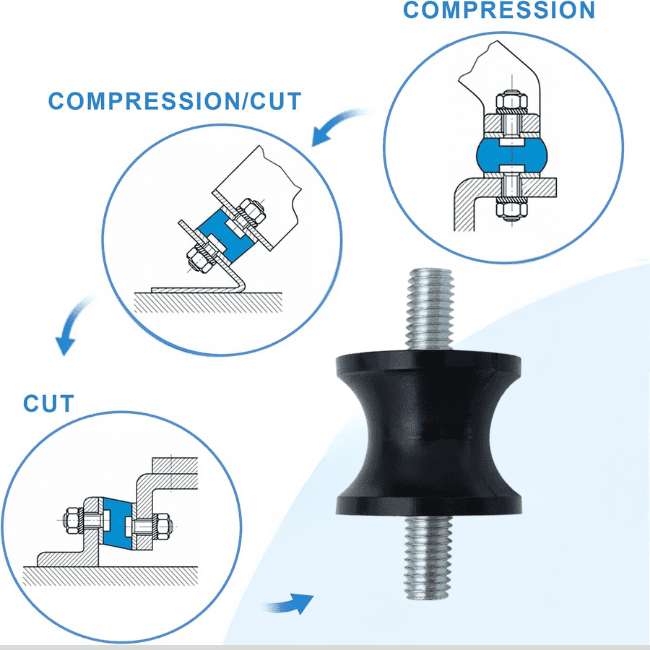

Installation Diagram Of GVV Type Waisted Cylindrical Rubber Mounts :

Installation Diagram of GVV Type Waisted Cylindrical Rubber Mounts

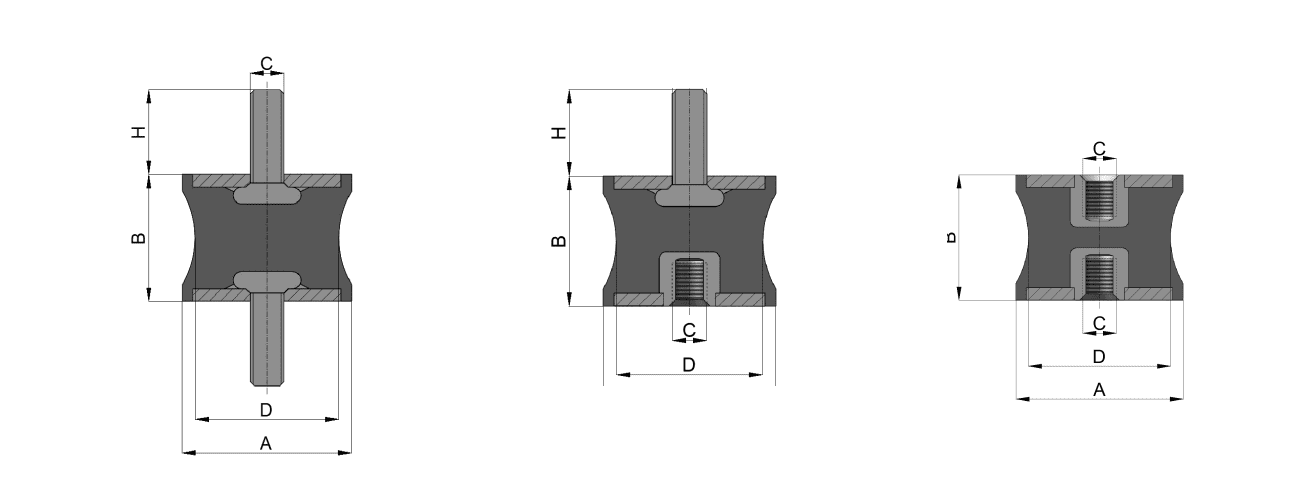

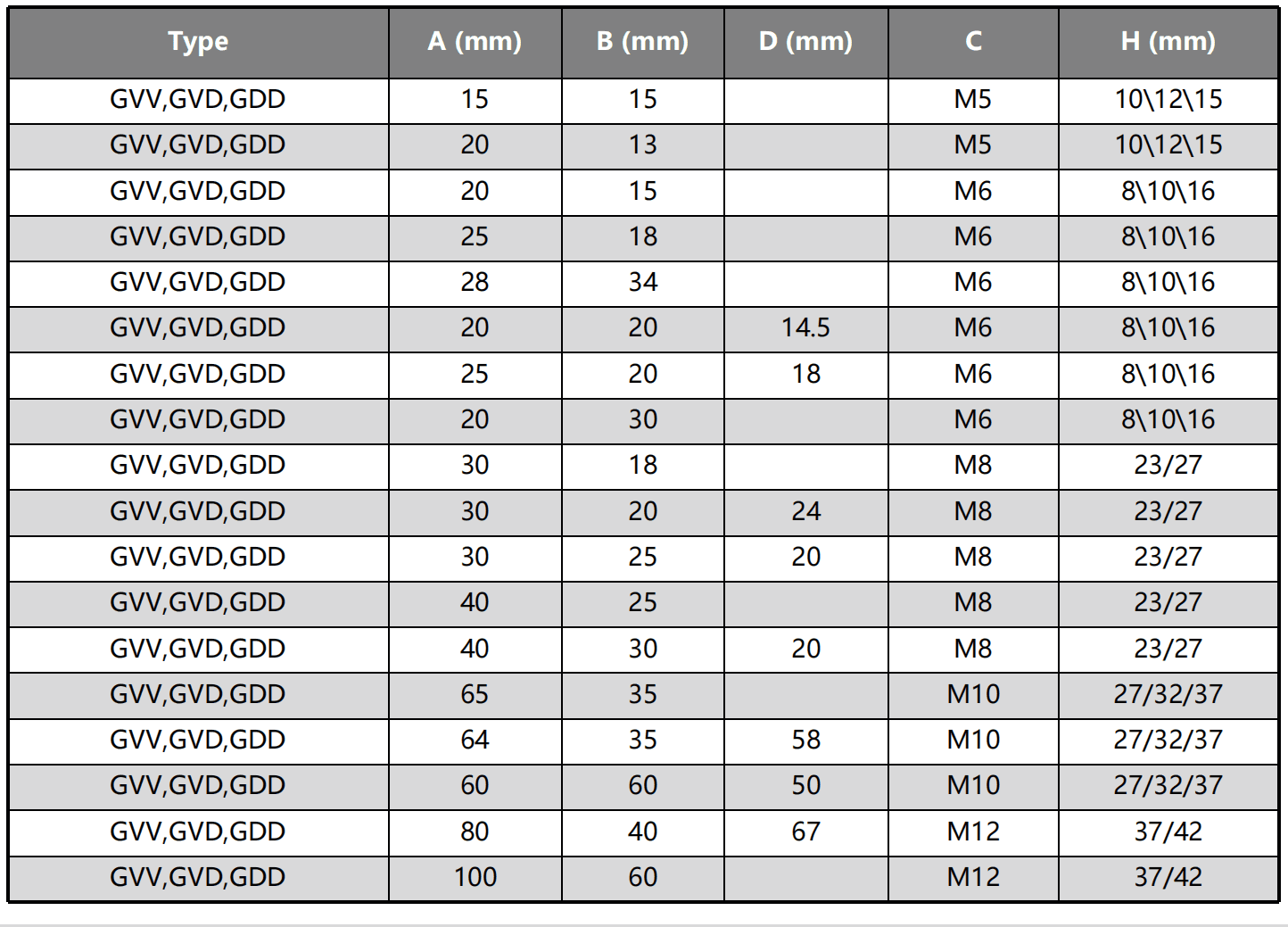

Parameter Table of GVV Type Waisted Cylindrical Rubber Mounts

If you like this Cylindrical Vibration Mount but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]