BGF Type Stainless Steel Bellows Expansion Joint

Flexible Strength, Reliable Safety

BGF Type Stainless Steel Bellows Expansion Joint– Product Introduction

The BGF Type Stainless Steel Bellows Expansion Joint is precision-engineered for industrial piping systems, providing reliable absorption of thermal expansion, vibration, and misalignment. Constructed from high-quality stainless steel, it offers exceptional corrosion resistance, high-temperature tolerance, and long-term durability, making it ideal for demanding applications.

The bellows design ensures multi-directional flexibility, allowing the joint to accommodate axial, lateral, and angular movements while minimizing stress on connected piping and equipment. This not only protects the pipeline from fatigue and structural damage but also contributes to the overall efficiency and stability of the system.

BGF Type expansion joints are widely used in chemical processing, petrochemical plants, power generation, pharmaceuticals, food and beverage, and other industrial sectors where reliability and safety are critical. Each unit can be customized in terms of diameter, pressure rating, and flange configuration to meet specific project requirements.

Engineered for both high-pressure and high-temperature environments, these stainless steel bellows expansion joints are tested for performance and compliance with international standards, ensuring consistent quality and operational reliability. Their robust construction, combined with flexible design, makes them a trusted solution for vibration isolation, thermal stress absorption, and long-term pipeline protection.

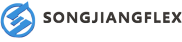

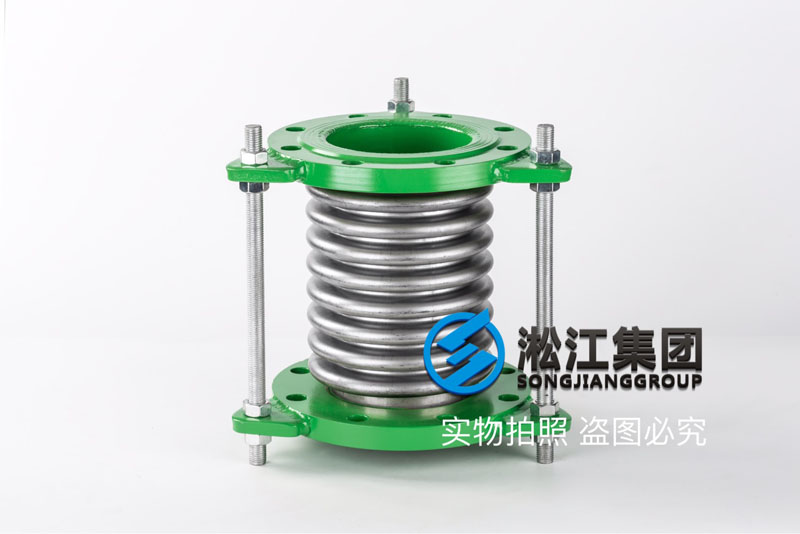

BGF Type Stainless Steel Bellows Expansion Joint – Product Photo

BGF Type Bellows Expansion Joints are widely used in industrial piping systems that require high reliability, high temperature, high pressure, or resistance to aggressive media. Key application areas include:

Chemical and Petrochemical Industries: For transporting corrosive liquids, acids, alkalis, and high-temperature or high-pressure media. They absorb thermal expansion and vibration, ensuring long-term stable operation of pipelines and equipment.

Power Generation and Thermal Systems: In steam, hot water, and fuel pipelines, the bellows absorb thermal expansion and mechanical vibration, protecting boilers, turbines, and heat exchangers from stress damage.

HVAC Systems: Used in large ventilation ducts to compensate for vibration and thermal expansion, maintaining stable airflow while reducing noise.

Pharmaceutical and Food Processing: Stainless steel construction ensures corrosion resistance, easy cleaning, and compliance with hygiene standards, suitable for high-purity fluids and food-grade pipelines.

Marine and Offshore Applications: Can withstand seawater and aggressive chemical environments over long-term operation.

In general, any pipeline system experiencing thermal expansion, vibration, or minor misalignment can benefit from the flexibility and stability provided by BGF Bellows Expansion Joints, extending equipment life and improving system efficiency.

The key feature of BGF Bellows is the flexible corrugated structure, which absorbs thermal expansion, contraction, and vibration through elastic deformation. Mechanisms include:

Axial Expansion Absorption: The bellows can extend or compress along the pipe axis under thermal expansion, converting thermal stress into elastic deformation to reduce flange and connected equipment stress.

Lateral Offset Compensation: Lateral misalignment caused by foundation settlement or installation errors is absorbed through sideways deflection.

Angular Movement Buffering: Bending or twisting is mitigated by corrugation deformation, consuming energy and reducing stress at connection points.

Vibration Damping: Vibrations from pumps, fans, mechanical equipment, or fluid pulsation are absorbed by the elasticity of the stainless steel bellows, significantly reducing transmission to supporting structures and lowering noise.

This multi-directional absorption protects pipelines and supporting structures, minimizes mechanical wear, and improves operational safety and stability.

BGF Bellows primarily use high-quality stainless steel, such as SS304 or SS316, to ensure excellent corrosion resistance, chemical compatibility, and high-temperature tolerance. Key points include:

Corrosion Resistance: SS304 is suitable for general industrial environments, while SS316 is recommended for highly corrosive or marine environments due to superior pitting and chloride resistance.

High-Temperature Performance: Stainless steel bellows can operate safely at temperatures up to 550°C or higher (depending on wall thickness and grade), making them suitable for steam, hot water, and thermal oil pipelines.

Flanges and Accessories: Flanges, reinforcement rings, and pressure plates can be made of stainless steel or carbon steel, based on project requirements.

Custom Material Options: For special chemical, pharmaceutical, or food applications, inner lining with PTFE or other corrosion-resistant materials can extend service life.

Proper material selection is critical to ensure reliable, long-term operation in high-temperature, high-pressure, or chemically aggressive environments.

Yes. BGF Bellows are designed for high-pressure and high-temperature applications. Their pressure and temperature ratings depend on wall thickness, material grade, flange design, and the number of corrugations. Key advantages:

High Pressure Capability: Thicker walls, increased corrugation count, and optimized flanges allow safe operation under steam, hot water, and chemical pressurized pipelines without permanent deformation or leakage.

High Temperature Tolerance: Stainless steel construction and precision welding ensure elasticity and sealing performance under elevated temperatures.

Continuous Operation Reliability: Even under ongoing thermal expansion and mechanical vibration, bellows maintain structural integrity and stable system operation.

Safety Factor Design: Each bellows is engineered with pressure and temperature safety calculations to meet various industrial standards and operating conditions.

BGF Bellows are a vital component for safe operation and reduced maintenance costs in high-temperature, high-pressure pipeline systems.

Service life depends on operating conditions, including pressure, temperature, chemical media, vibration, and installation quality. Under proper installation, calibration, and maintenance:

BGF Bellows typically last many years, often exceeding 10 years under standard conditions.

Regular inspection can detect corrosion, fatigue, or misalignment early, extending operational life.

High-quality stainless steel and precision design ensure reliable performance even under continuous high-temperature and high-pressure operation.

Long-term use reduces pipeline failure risks, minimizes downtime, and significantly lowers maintenance costs, making bellows a long-term investment in pipeline system reliability.

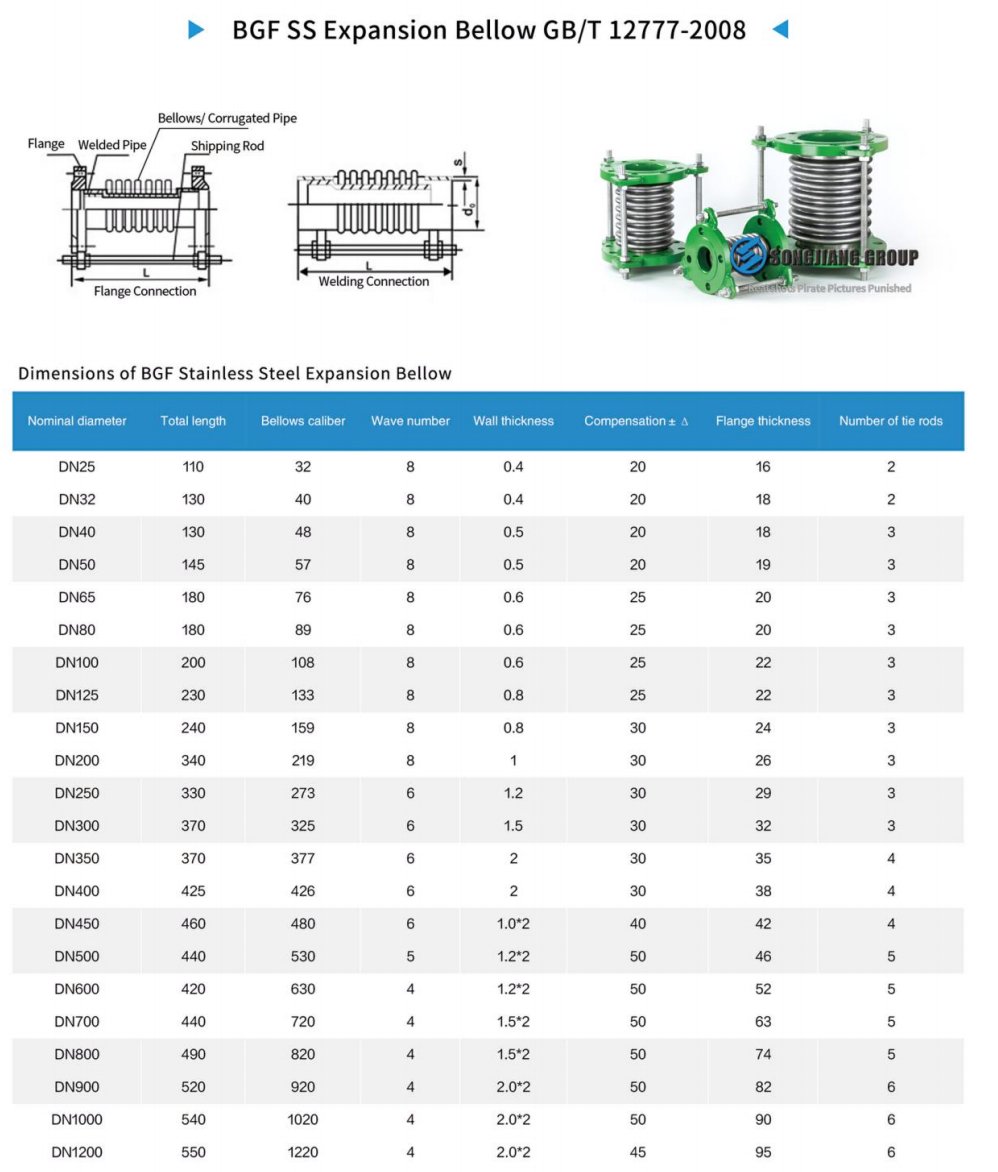

Datasheet for BGF Type Bellows Expansion Joints

Daily Production Showcase from Factory

Advantages of Using BGF Type Bellows Expansion Joints

Absorbs Thermal Expansion and Contraction – BGF Type Bellows Expansion Joints are engineered to effectively compensate for axial, lateral, and angular movements caused by thermal expansion or contraction in piping systems. This ensures that flanges, joints, and connected equipment are protected from excessive stress, deformation, and potential damage, improving overall pipeline reliability.

Vibration and Noise Reduction – The flexible stainless steel design helps dampen vibrations generated by pumps, fans, or other mechanical equipment. This not only reduces noise levels in industrial facilities but also minimizes mechanical fatigue, prolonging the service life of both the piping system and connected machinery.

Corrosion and Chemical Resistance – Constructed from premium stainless steel materials such as SS304 or SS316, BGF Bellows Expansion Joints offer outstanding resistance to corrosion, chemical attack, and harsh environmental conditions. SS316 is particularly suitable for highly corrosive or marine applications, ensuring long-term durability and safe operation.

High Pressure and Temperature Capability – These expansion joints are specifically designed to withstand high-pressure and high-temperature conditions commonly found in steam, hot water, and chemical pipelines. The robust construction prevents permanent deformation and ensures continuous, reliable operation even under extreme industrial conditions.

Leak Prevention and System Reliability – With precision-engineered bellows, reinforced flanges, and secure fastening systems, BGF Bellows Expansion Joints provide excellent sealing performance. This minimizes the risk of leaks, protects critical equipment, and helps maintain uninterrupted operation, which is essential for industrial efficiency and safety.

Customizable Design – Every pipeline system is unique, and BGF Bellows Expansion Joints can be fully customized according to pipe diameter, pressure rating, temperature range, and type of movement. This flexibility ensures that each joint provides optimal performance, adapts perfectly to operational requirements, and maximizes the service life of the entire piping network.