RM BELL MOUNTS

Strong Support, Quiet Operation – Discover the RM Series Bell Mounts Advantage

RM SERIES BELL MOUNTS

RM Series Bell Mounts are primarily used for vibration isolation and noise reduction in industrial equipment. They are ideal for heavy machinery such as engines, generators, pumps, compressors, and HVAC systems. By absorbing vibration and shock, these mounts prevent energy from being transmitted to the supporting structures, which protects both the equipment and the surrounding environment. They are particularly useful in situations where precision and reliability are critical, such as power generation plants, industrial workshops, and automated production lines. The mounts can handle both static and dynamic loads, making them versatile for a wide range of industrial applications. Properly installed RM Bell Mounts can significantly extend the service life of machinery by reducing mechanical stress and minimizing wear on connected components.

RM Series Bell Mounts combine high-quality elastomeric rubber with a durable metal insert, creating a mount that is both flexible and strong. The rubber is specially formulated to resist oil, grease, industrial chemicals, and moderate heat, ensuring reliable performance in harsh environments. The metal insert provides structural support and ensures that the mount can handle high static and dynamic loads without deforming permanently. The rubber also exhibits high hysteresis, which allows it to effectively dampen vibration across a wide frequency range. This combination of materials gives RM Series Bell Mounts a long service life, even under heavy-duty operating conditions, and makes them suitable for applications where both vibration isolation and load support are equally important.

RM Series Bell Mounts function by using the elastic deformation of the rubber component to absorb and dissipate vibrational energy. The bell-shaped design allows the rubber to compress and expand in multiple directions, which reduces the transmission of vibrations and shocks to the surrounding structures. The metal insert provides the necessary mechanical strength to support heavy loads and maintain the mount’s shape under pressure. This design ensures that vibrations generated by engines, generators, or other machinery are not transferred to floors, walls, or connected equipment, which reduces noise, structural stress, and potential mechanical damage. By combining flexibility and strength, RM Series Bell Mounts achieve a balanced performance, isolating both low-frequency vibrations caused by heavy loads and higher-frequency vibrations from mechanical oscillations.

Yes, RM Series Bell Mounts are specifically designed to support heavy industrial machinery. The combination of a metal insert and high-quality rubber ensures that the mount can withstand large static and dynamic loads without permanent deformation. This makes them suitable for large diesel engines, generators, pumps, compressors, and other heavy equipment. The bell-shaped rubber design allows the mount to absorb shocks from start-up, operational vibrations, and sudden load changes, preventing stress from transferring to the supporting frame or foundation. When correctly selected based on load and vibration frequency, RM Bell Mounts extend equipment life, reduce maintenance costs, and improve operational stability, even in continuous heavy-duty applications.

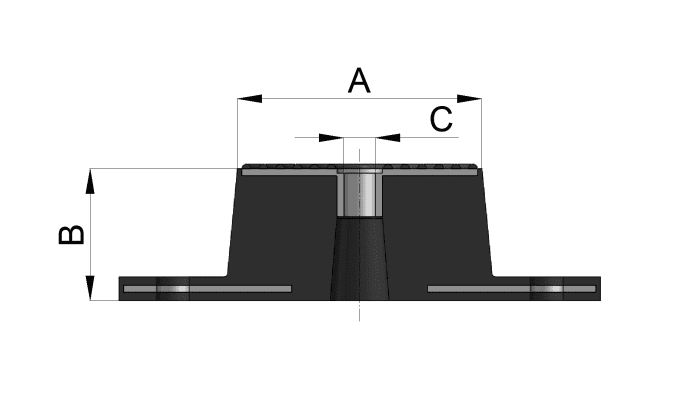

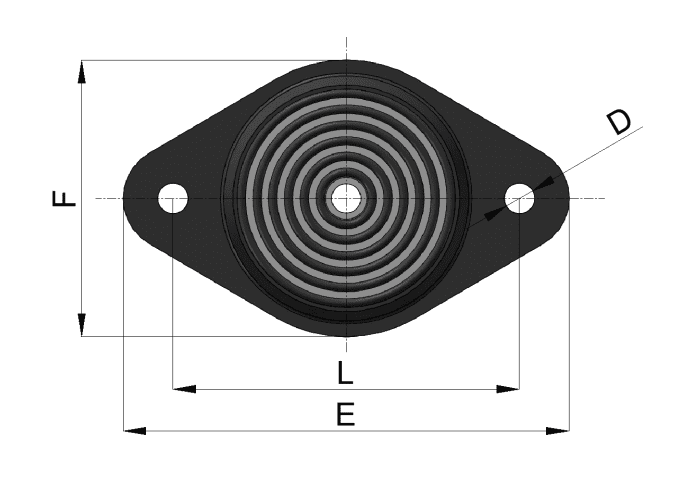

Installation Diagram of RM SERIES BELL MOUNTS

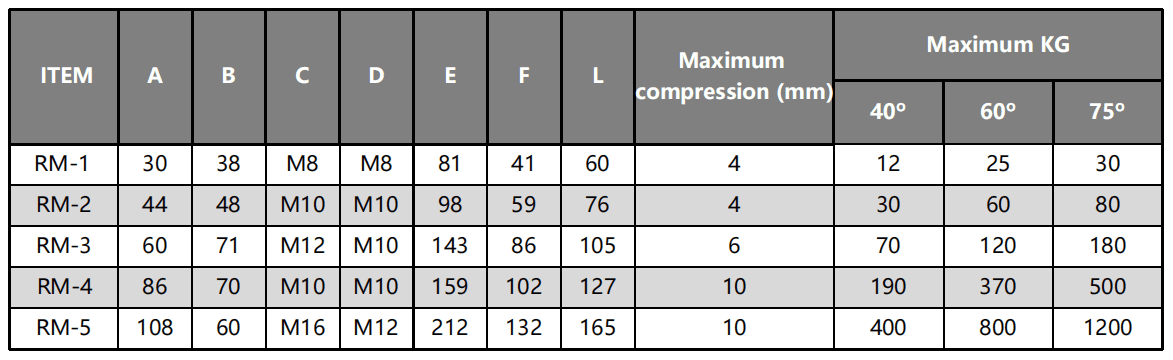

Parameter Table of RM SERIES BELL MOUNTS

If you like this RM SERIES BELL MOUNTS but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]