FRH/FRS – FRHQ/FRSQ Bell Mounts

Exceptional Care Provided by Highly Experienced Dental Professionals

FRH/FRS - FRHQ/FRSQ Bell Mounts

The greatest advantage of FRH/FRS - FRHQ/FRSQ Rubber Bell Mounts lies in their unique bell-shaped geometry. This design effectively distributes loads and avoids the common issue of stress concentration found in conventional cylindrical or plate-type mounts. In traditional designs, forces are often concentrated in localized areas, which leads to cracking, permanent deformation, or even failure after prolonged use. The bell shape, however, expands the contact surface and optimizes stress pathways, ensuring that forces are transmitted more evenly. This significantly improves durability and operational stability.

In addition, FRH/FRS - FRHQ/FRSQ mounts are manufactured using high-performance rubber compounds with excellent elasticity and damping properties. They are capable of absorbing low-frequency vibrations while simultaneously suppressing high-frequency shocks, delivering broad-spectrum vibration isolation. This is something that traditional mounts often struggle to achieve. Moreover, the bell-shaped structure offers greater stability under dynamic conditions, maintaining consistent vibration control even during frequent start-stop cycles or fluctuating loads.

In short, FRH/FRS - FRHQ/FRSQ mounts solve the problems of short lifespan and limited vibration range in conventional products, while delivering superior reliability and versatility. They are particularly well-suited for modern industrial applications that demand stringent vibration control.

In industrial equipment, vibration is not merely a noise issue—it is one of the main causes of reduced efficiency and shortened component lifespan. FRH/FRS Rubber Bell Mounts play a critical role by delivering highly effective isolation and damping, which directly enhances both efficiency and reliability.

First, when machines operate under vibration, they experience extra friction, impact, and energy loss. For instance, in compressors or pumps, vibration can cause shaft misalignment, abnormal loads on bearings, and increased energy consumption. FRH/FRS - FRHQ/FRSQ mounts suppress these unnecessary energy losses, allowing equipment to run under optimal conditions and reducing power or fuel consumption.

Second, vibration accelerates wear and tear on mechanical parts, shortening maintenance cycles and increasing downtime risks. By reducing vibration transmission, FRH/FRS - FRHQ/FRSQ significantly lowers fatigue damage on components, extending the overall service life of the system. This means lower maintenance costs, fewer shutdowns, and more consistent production uptime.

Finally, long-term stability not only improves efficiency but also enhances product quality. In precision manufacturing, vibration directly affects accuracy and consistency. By minimizing unwanted movement, FRH/FRS - FRHQ/FRSQ ensures higher precision in production processes. Thus, FRH/FRS - FRHQ/FRSQ mounts are not just vibration isolators—they are key solutions for improving equipment performance and operational reliability.

Industrial environments are rarely ideal. Many machines must operate under extreme conditions such as high humidity, corrosive chemicals, drastic temperature variations, or prolonged outdoor exposure. FRH/FRS - FRHQ/FRSQ Rubber Bell Mounts have been specially engineered to maintain excellent performance even in such harsh environments.

The key lies in the advanced rubber compound. It offers outstanding resistance to oil, ozone, and chemical exposure, ensuring that the material does not degrade, crack, or lose elasticity over time. The rubber also demonstrates exceptional weather resistance, meaning it maintains stable performance even under continuous UV radiation or outdoor operation.

In terms of temperature adaptability, FRH/FRS - FRHQ/FRSQ mounts are designed to function across a wide temperature range. Whether it’s material contraction in cold environments or thermal expansion in high-heat conditions, the rubber compound retains its elasticity and damping properties. This makes it particularly valuable in applications such as energy equipment, HVAC systems, or heavy outdoor machinery.

Moreover, the bell-shaped structure itself provides enhanced stability, allowing the mount to withstand vibration and environmental stress without rapid deterioration. Taken together, FRH/FRS - FRHQ/FRSQ delivers a durable and reliable vibration isolation solution even under extreme operational conditions, significantly expanding its scope of application.

With the rise of Industry 4.0 and smart manufacturing, vibration control is no longer just about reducing noise or protecting equipment. Instead, it has become essential for ensuring high precision and operational stability. FRH/FRS - FRHQ/FRSQ Rubber Bell Mounts are designed with this in mind, making them an excellent fit for automated production lines and precision manufacturing systems.

In automation, equipment such as robots, CNC machines, and inspection devices are extremely sensitive to vibration. Even minor vibrations can cause reduced machining accuracy or measurement errors. FRH/FRS - FRHQ/FRSQ mounts, with their wide-frequency vibration isolation characteristics, ensure that these systems maintain exceptional stability, thereby safeguarding consistency and quality in production.

Another critical aspect of automation is long-term continuous operation under high load and fast cycles. Thanks to their optimized stress distribution and durable materials, FRH/FRS - FRHQ/FRSQ mounts provide consistent vibration damping over extended use, reducing fatigue-related failures.

Equally important is their ease of installation and low maintenance requirements, which align perfectly with the “low-maintenance, high-reliability” philosophy of smart factories. They can also be integrated into hybrid vibration control systems, working alongside air springs or steel spring isolators for advanced solutions.

In essence, FRH/FRS - FRHQ/FRSQ mounts are not just vibration isolators but enablers of precision, efficiency, and reliability in modern smart manufacturing and automated industries.

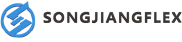

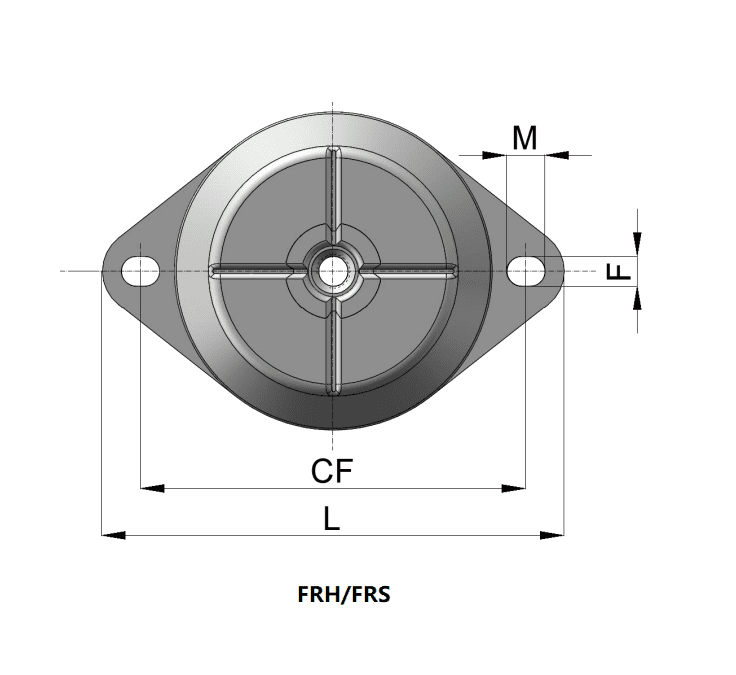

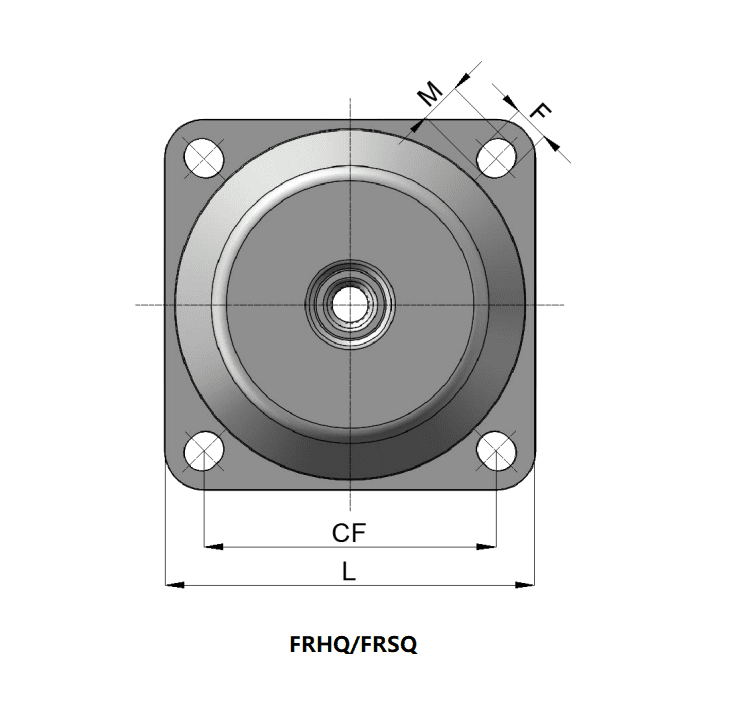

Installation Diagram of FRH/FRS - FRHQ/FRSQ Bell Mounts

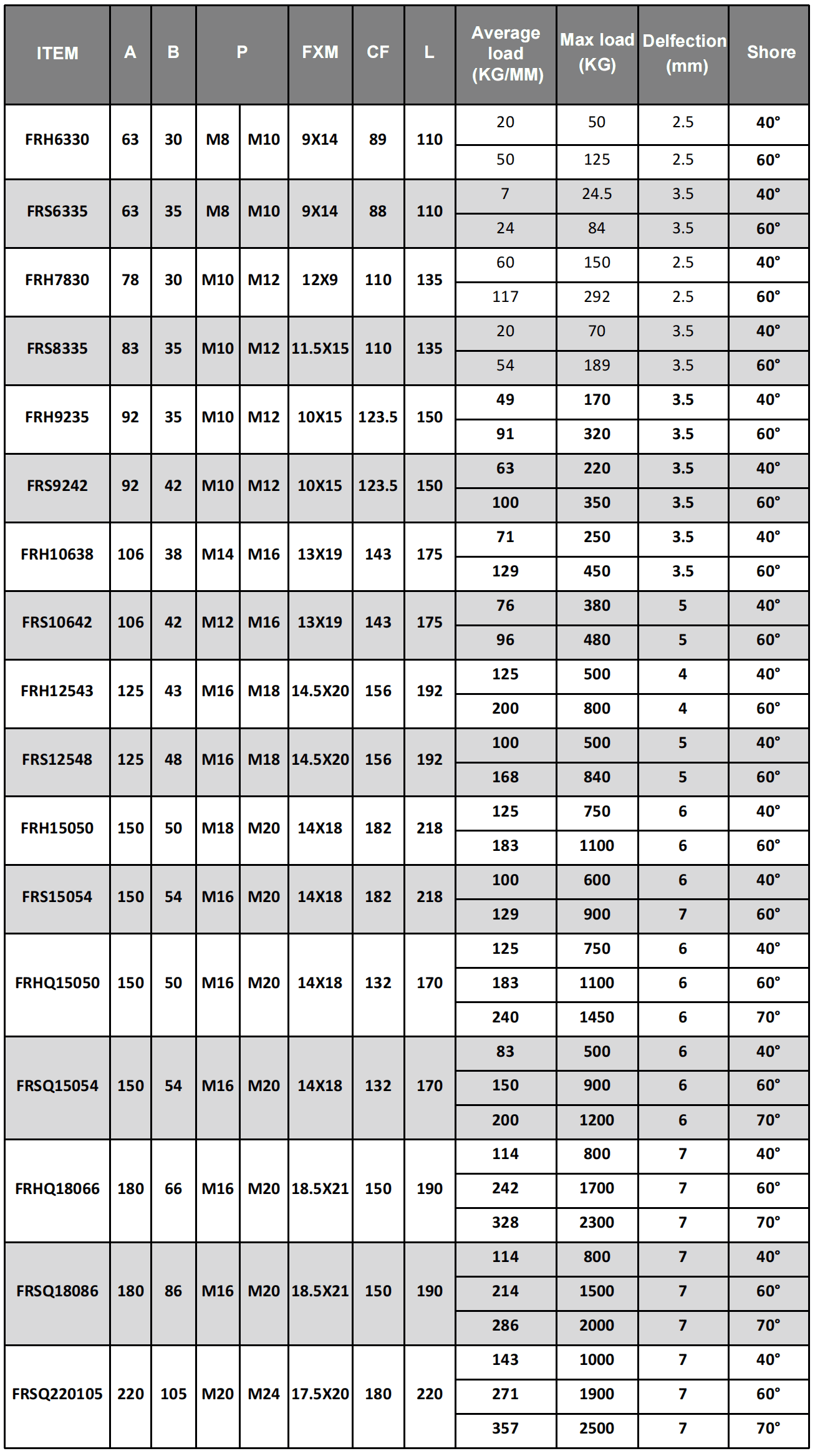

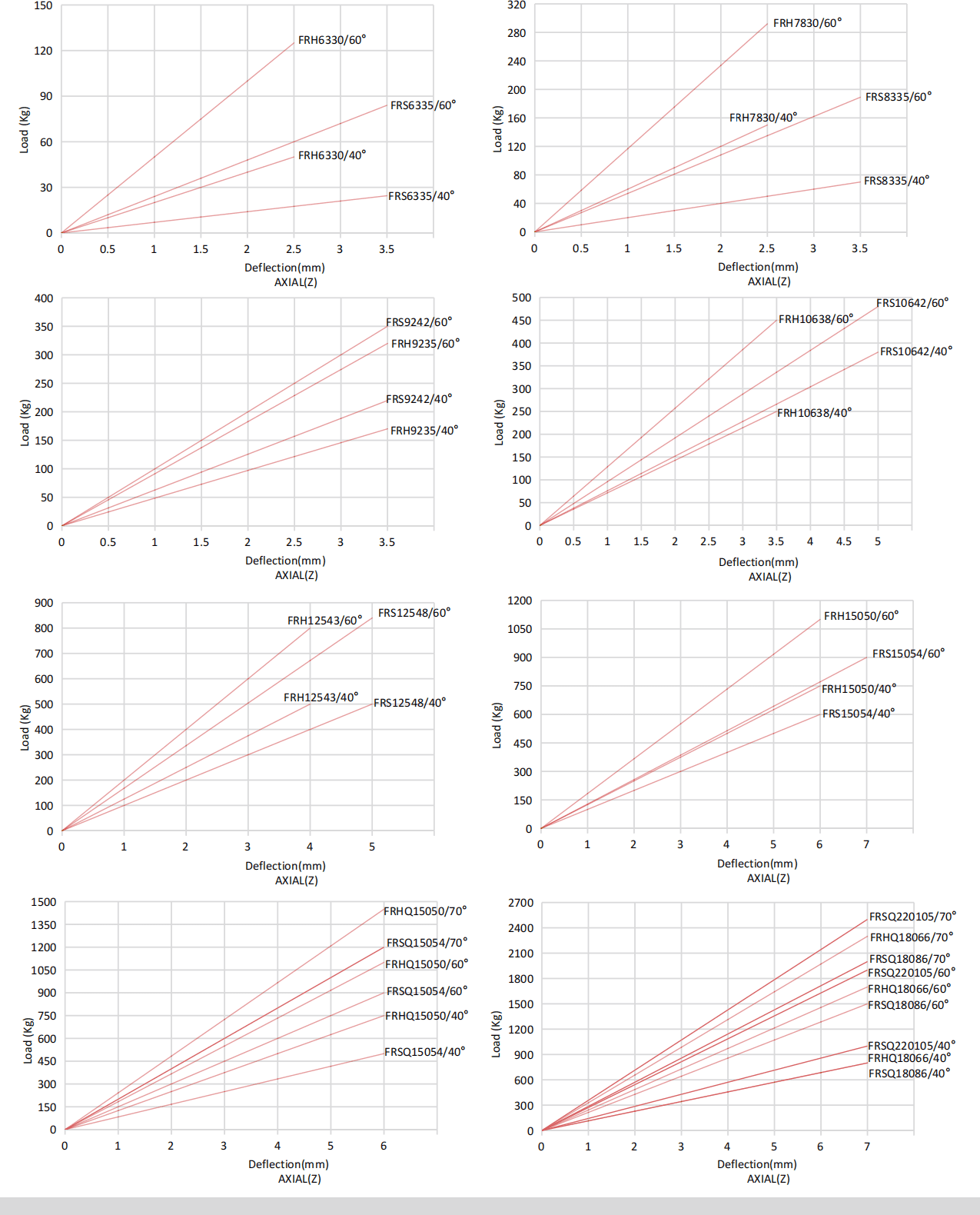

Parameter Table of FRH/FRS - FRHQ/FRSQ Bell Mounts

If you like this FRH/FRS – FRHQ/FRSQ Bell Mounts but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]