CN Series Cone Mounts

Discover the CN Series Cone Mounts – Built for Stability and Strength

CN Series Cone Mounts

The CN Series Cone Mounts are specifically engineered to isolate low to medium-frequency vibrations. Their natural frequency typically ranges between 8Hz to 20Hz, depending on several factors including the rubber hardness (Shore A), the static load per mount, the geometry of the cone, and the number of support points under the equipment.

To avoid resonance, it's crucial that the equipment's operating frequency (typically its motor speed or cyclic load frequency) remains at least 1.4 to 2 times higher than the mount's natural frequency. This ensures that vibration energy is not amplified through resonance.

In real-world applications, especially for HVAC units, pumps, and diesel gensets, we advise users to submit accurate data on weight, load distribution, and operational frequencies so that we can perform precise dynamic analysis. We provide tools such as frequency ratio calculations, load-deflection charts, and isolation efficiency predictions to help customers make informed decisions and ensure their equipment remains stable and protected.

CN Series Cone Mounts offer a sophisticated nonlinear stiffness response, which is difficult to achieve with flat rubber pads or traditional rectangular isolators. The conical shape ensures that as the load increases, the stiffness of the mount also increases proportionally. This variable stiffness improves vibration isolation under light loads while preventing excessive deflection under heavy loads.

Additionally, the three-dimensional flexibility of the conical profile provides isolation in both vertical and lateral directions, making them ideal for dynamic equipment experiencing multidirectional forces. Key advantages include:

Progressive load response: The cone geometry allows for soft initial damping with a stiffer rebound, excellent for shock loads.

Superior fatigue resistance: Due to distributed stress zones, CN mounts have a longer service life under cyclic loading.

Built-in displacement control: The cone design naturally limits maximum displacement, helping prevent equipment instability during startup or emergency stops.

Compact yet powerful: High isolation performance in a small footprint, suitable for equipment with limited installation space.

These features make CN cone mounts particularly valuable in demanding environments where equipment runs continuously or must endure frequent start-stop cycles.

CN cone mounts are versatile and designed for medium to heavy-duty applications where vibration isolation, structural integrity, and reliability are priorities. Their use spans across multiple industries, including:

Diesel and Gas Engines: Engine vibrations are often irregular and intense. CN mounts effectively dampen vertical shocks and horizontal torque-induced motion.

HVAC Compressors and Fans: They reduce transmission of low-frequency noise and structure-borne vibration into buildings or rooftop platforms.

Industrial and Process Pumps: Especially in chemical plants or water treatment facilities, where continuous operation requires high reliability.

Generator Sets and Electrical Cabinets: Protect sensitive electronic components from shock and ensure quieter operation.

Mobile Machinery and Vehicles: From compact excavators to off-road trucks, CN mounts help stabilize equipment under motion and uneven terrain.

These mounts are also suitable for portable equipment, modular systems, and any machinery that must maintain high performance with minimal vibration interference.

Choosing the right CN cone mount model is essential for achieving optimal vibration isolation and ensuring the safety of both the equipment and its foundation. The following data should be provided for an accurate recommendation:

Total weight of the equipment and the number of mounts used (to calculate static load per mount)

Operating frequency (rpm or Hz) of the machine to avoid resonance

Installation footprint and space constraints

Mounting interface (stud, through-hole, base plate, or flange)

Environmental conditions (exposure to oil, water, chemicals, temperature range, outdoor vs indoor use)

Using this data, our engineering team can suggest the most appropriate mount type and size. We provide supporting documents such as technical datasheets, CAD drawings, load vs. deflection curves, and even finite element analysis (FEA) models upon request. We also assist in developing custom solutions for specialized or non-standard applications.

CN cone mounts are constructed from durable elastomer materials such as natural rubber (NR) for general use or neoprene (CR) for environments with mild oil and ozone exposure. The standard temperature range is -20°C to +80°C, and custom compounds can expand that range to -40°C or +100°C if required.

For the metal components, options include galvanized steel, painted steel, or stainless steel depending on the application. This ensures strong resistance to rust, chemical corrosion, and UV degradation, making CN mounts suitable for outdoor and marine use.

Under normal indoor industrial conditions, the mounts can last 5 to 8 years or more. In aggressive environments—such as offshore platforms, refineries, or areas with chemical mist—mount lifespan can still be extended by using enhanced materials and protective coatings.

Each unit is tested for fatigue, compression set, and tensile strength during production to ensure high performance and reliability. Maintenance is minimal, but regular inspections (every 6 to 12 months) are recommended to check for signs of hardening, cracking, or detachment.

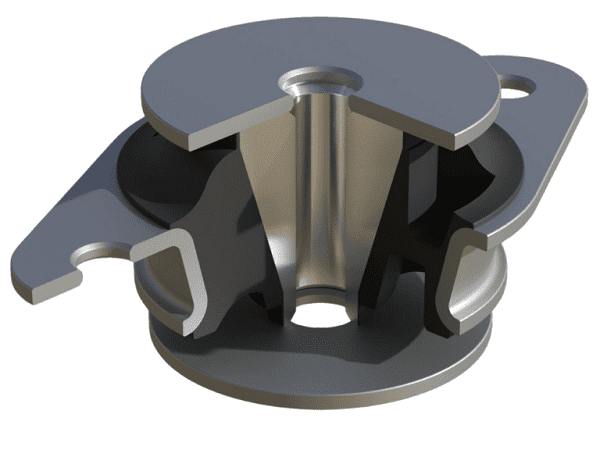

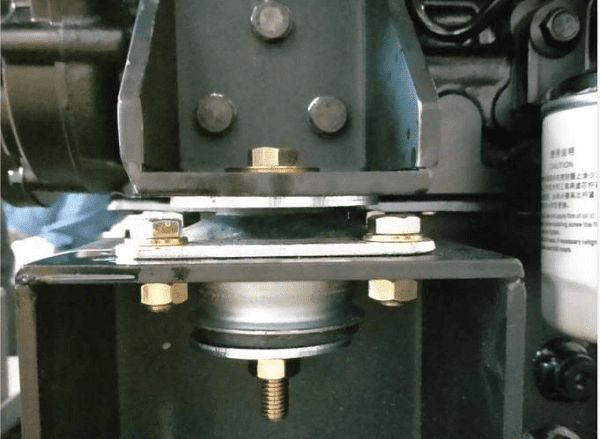

CN Cone Mounts And Application Scenarios Diagram

CN Cone Mounts are highly versatile vibration isolators designed to absorb shocks and reduce structure-borne noise in industrial and mechanical systems. Made from high-grade rubber and steel components, they provide excellent axial and radial load resistance. These mounts are particularly suitable for equipment with dynamic loads and frequent vibration cycles.

Typical application scenarios include:

Diesel generator sets

Pumps and compressors

HVAC units

Construction machinery

Marine engines and onboard equipment

The diagram visually presents how CN Cone Mounts are installed in different machinery, helping engineers and maintenance teams select and apply the correct model for maximum efficiency.

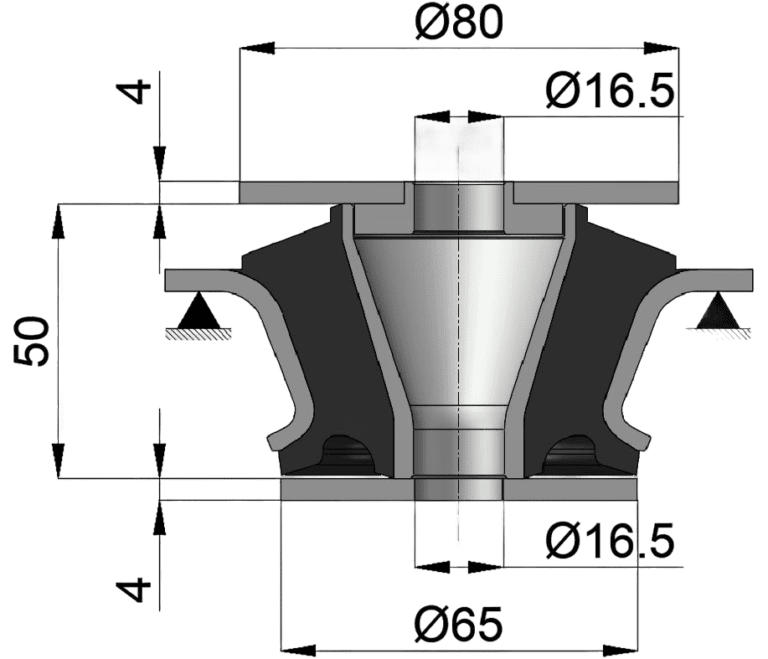

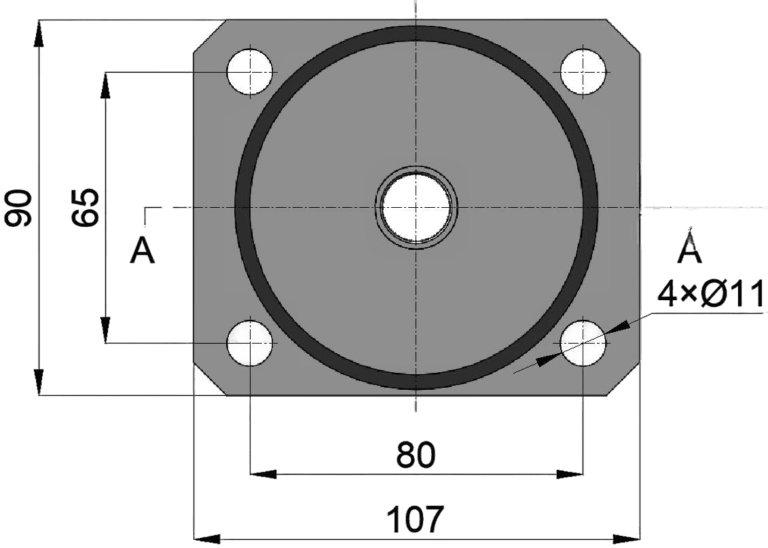

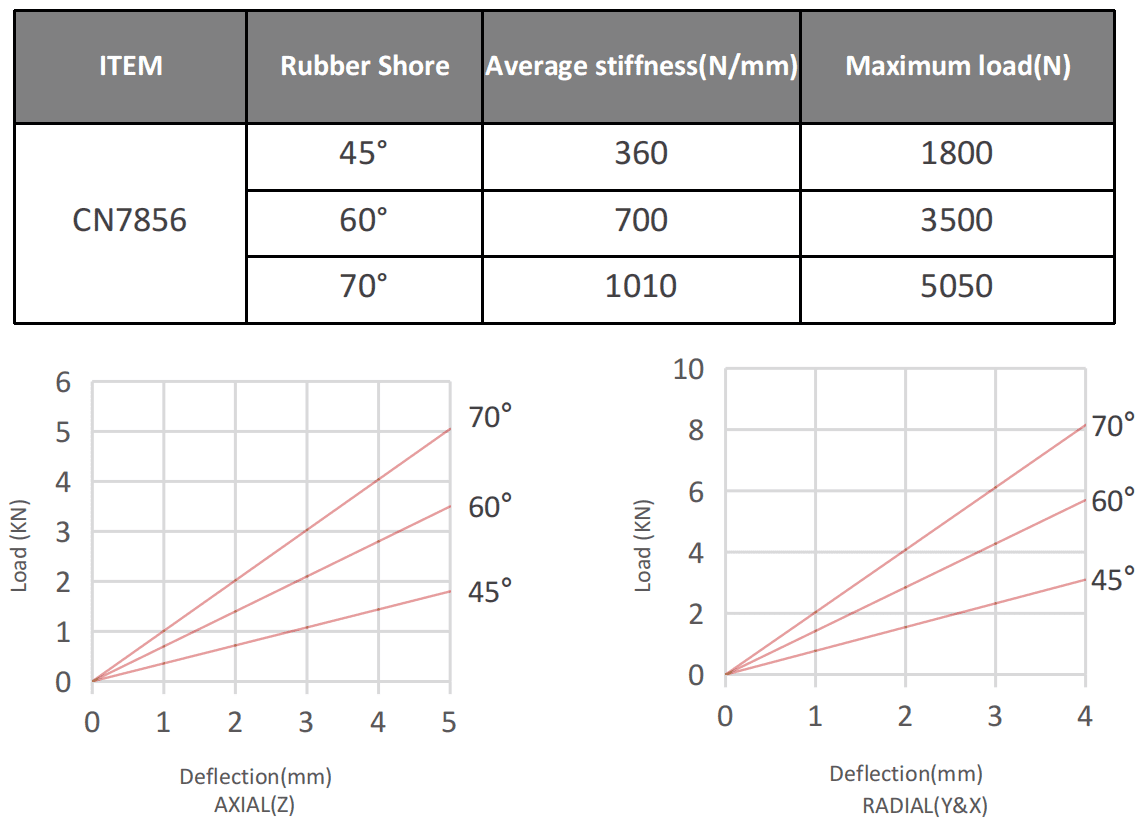

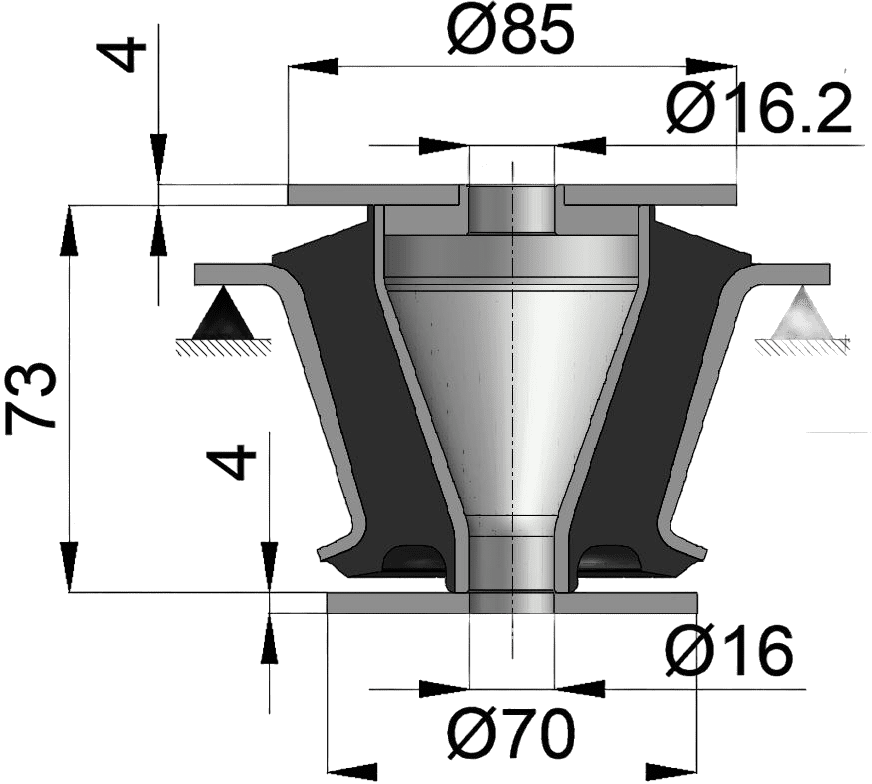

CN7856 Cone Mounts Analysis Diagram

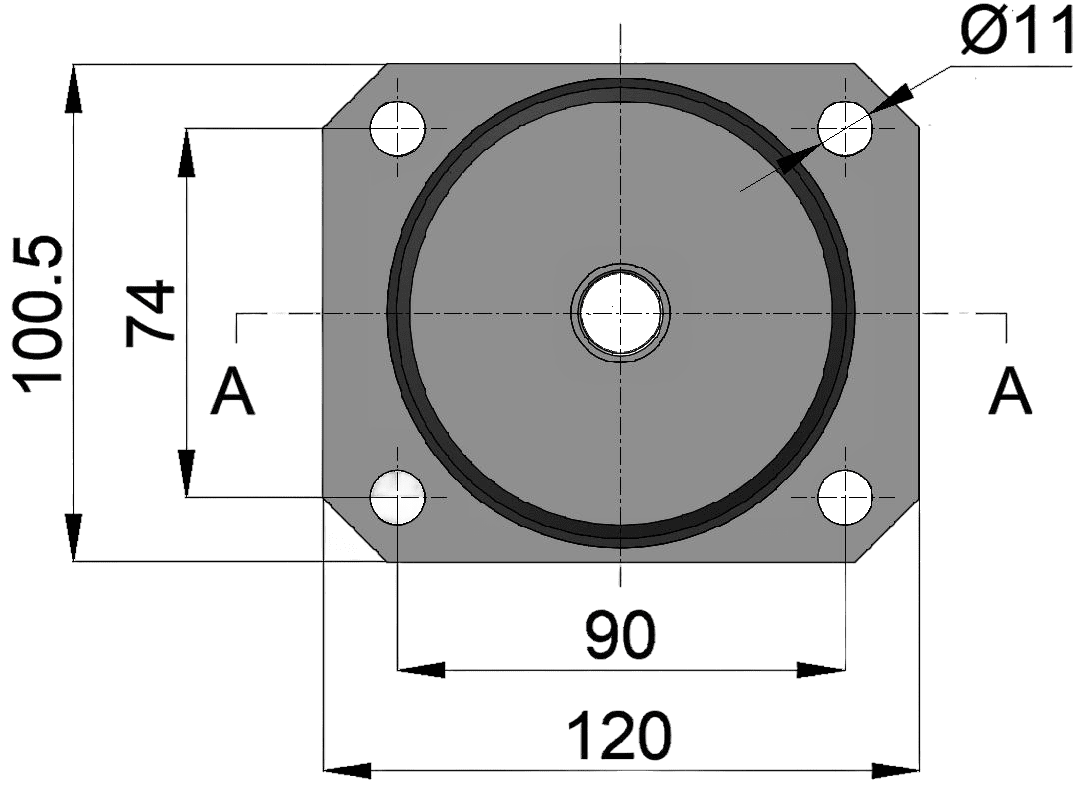

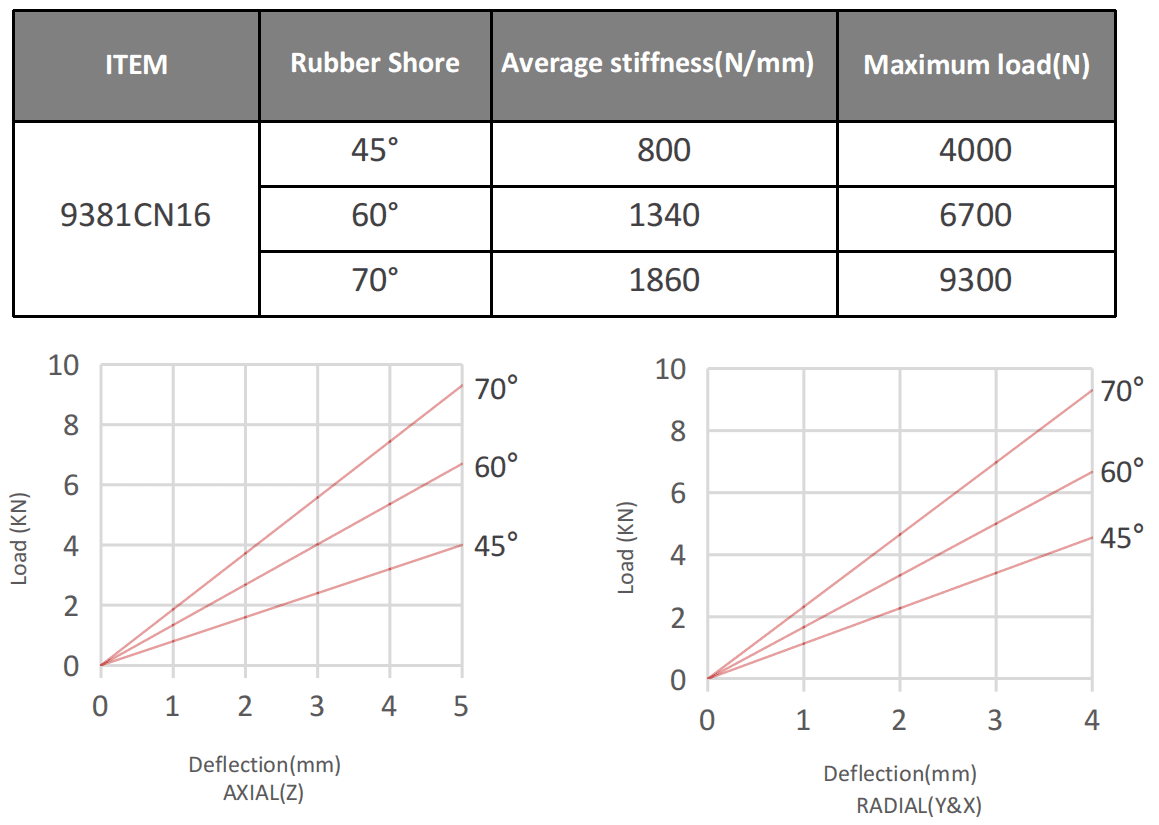

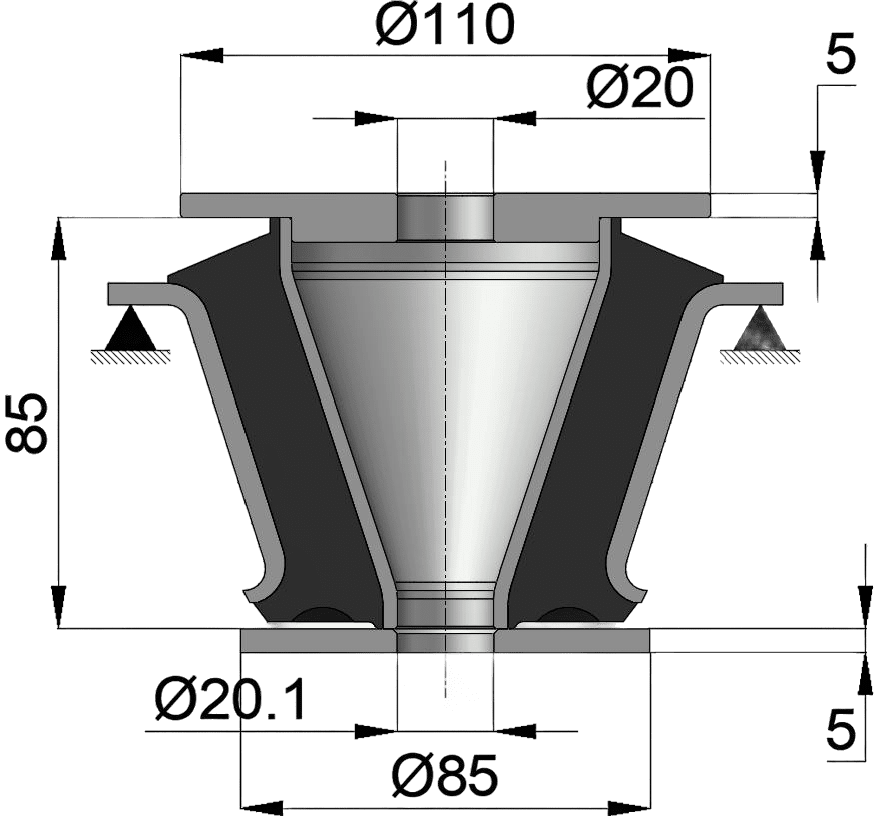

9381CN16 Cone Mounts Analysis Diagram

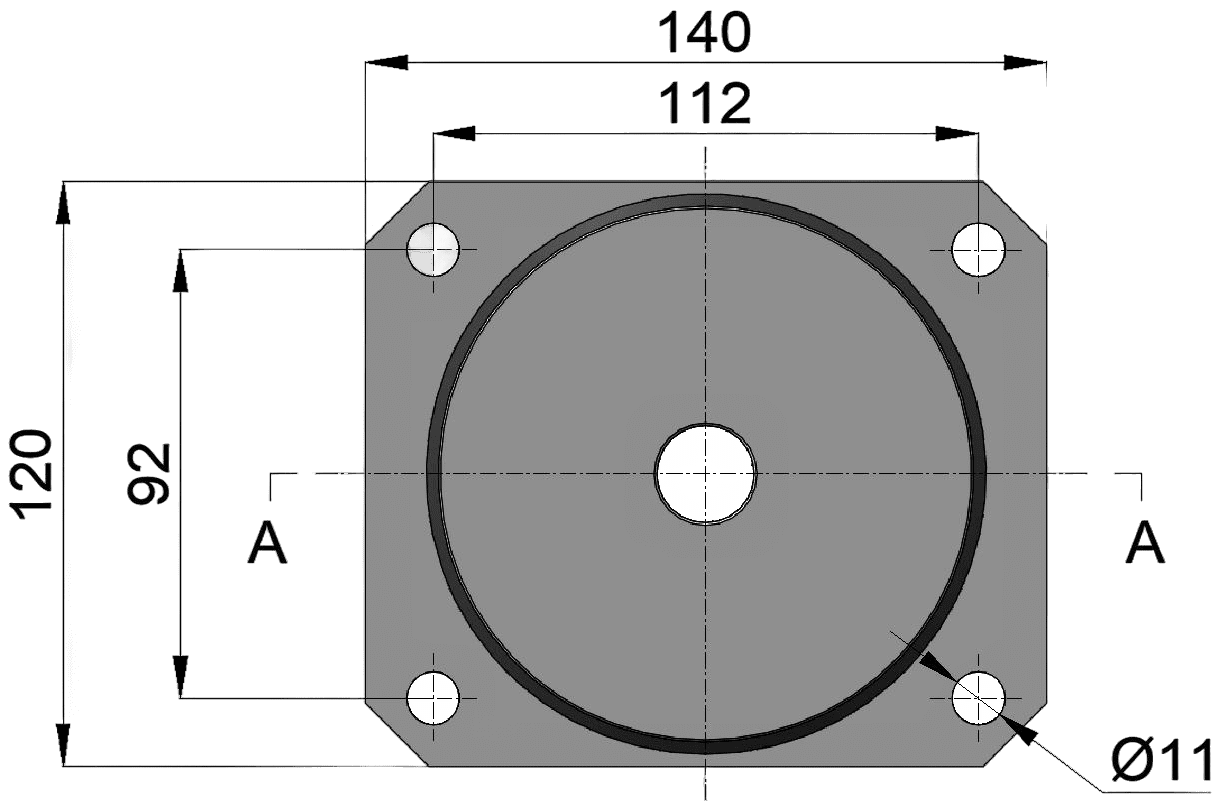

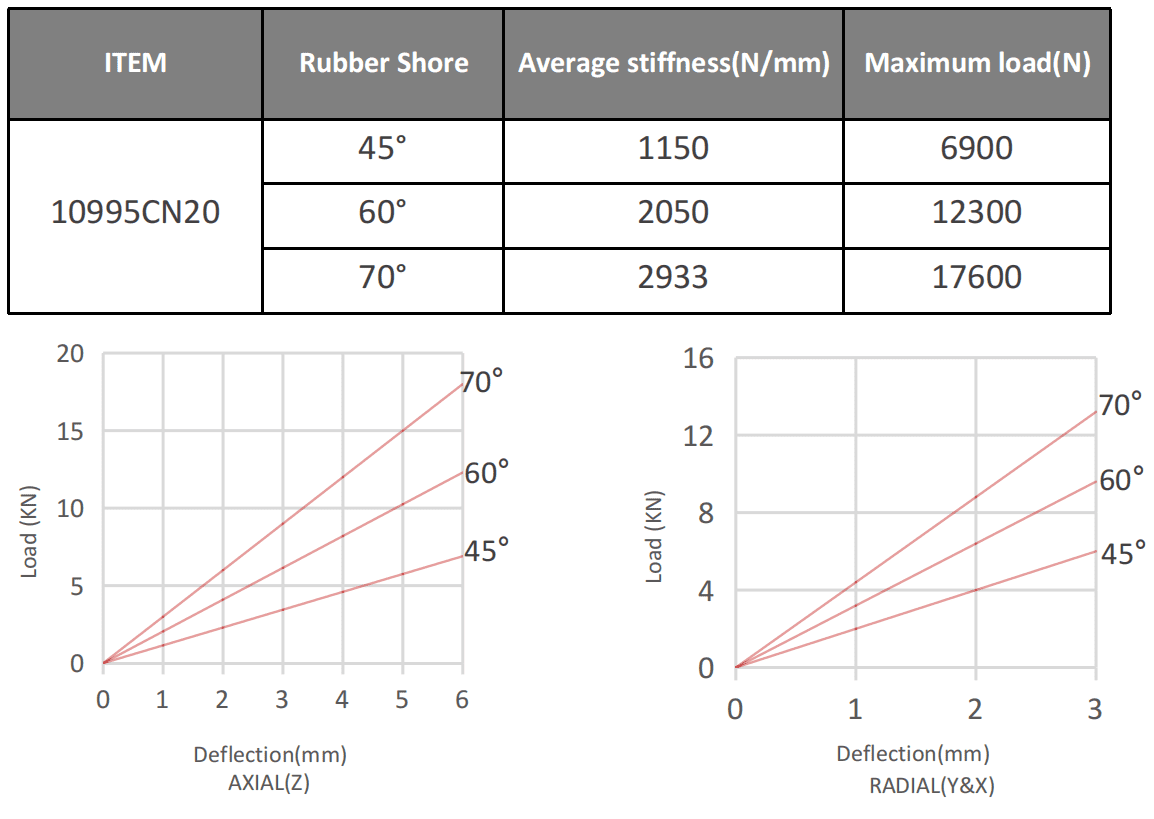

10995CN20 Cone Mounts Analysis Diagram

If you like this CN Series Cone Mounts but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]