WCR-L Type Anti-Settlement Winding Rubber Expansion Joint

Flexible Strength, Reliable Safety

WCR-L Type Anti-Settlement Winding Rubber Expansion Joint – Product Introduction

The WCR-L Type Anti-Settlement Winding Rubber Expansion Joint is specially designed to compensate for pipeline displacement caused by foundation settlement, vibration, and thermal expansion. Featuring a reinforced winding structure, this expansion joint provides enhanced axial strength and long-term stability, effectively preventing excessive deformation and pipeline stress.

Manufactured from high-quality rubber materials combined with high-strength winding reinforcement, the WCR-L type offers excellent pressure resistance, flexibility, and fatigue durability. The anti-settlement design ensures reliable performance in uneven ground conditions, reducing the risk of pipeline misalignment, leakage, and structural damage.

This expansion joint is widely used in water supply and drainage systems, HVAC pipelines, industrial process pipelines, power plants, and municipal engineering projects, where ground settlement and vibration are common challenges. Its flexible structure efficiently absorbs vibration, isolates noise, and protects connected equipment and pipelines.

With easy installation, low maintenance requirements, and a long service life, the WCR-L Type Anti-Settlement Winding Rubber Expansion Joint is a reliable solution for ensuring pipeline safety, operational stability, and reduced maintenance costs in demanding environments.

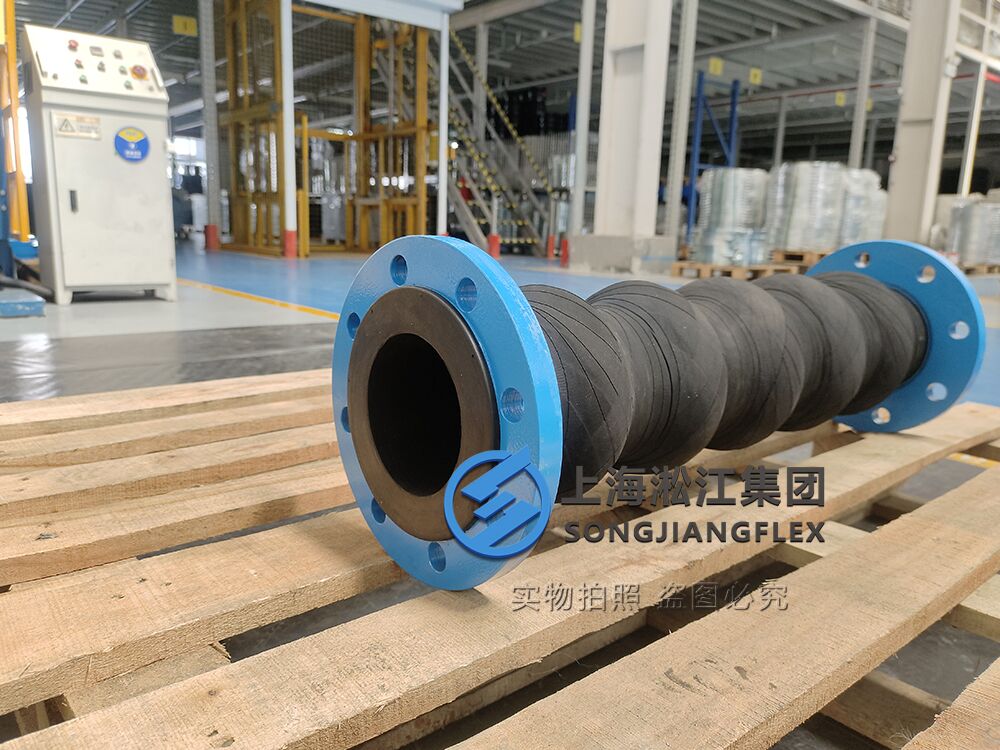

WCR-L Type Anti-Settlement Winding Rubber Expansion Joint – Product Photo

The WCR-L Type Anti-Settlement Winding Rubber Expansion Joint is a specialized pipeline component designed to provide flexible connection and displacement compensation in various industrial and municipal piping systems. Unlike traditional rigid connections, this expansion joint is built with a reinforced winding structure that combines high-quality rubber with embedded high-strength fibers or steel cords. This design allows it to absorb and mitigate the effects of axial, lateral, and angular movements caused by external factors such as ground settlement, thermal expansion, vibrations, and mechanical stresses.

The primary purpose of the WCR-L expansion joint is to protect pipelines and connected equipment from stress concentration and premature wear. When pipelines experience uneven settling due to soil consolidation, seismic activity, or foundation shifts, rigid joints can experience high local stress, leading to cracks, leaks, or even catastrophic failure. The WCR-L expansion joint accommodates these movements through its flexible body, preventing structural damage and prolonging system lifespan.

This type of expansion joint is commonly applied in water supply and drainage systems, HVAC pipelines, industrial process lines, power generation facilities, and municipal engineering projects. It is particularly effective in systems where uneven foundation settlement or heavy mechanical vibrations are anticipated. The anti-settlement feature ensures that the joint maintains its shape and alignment under long-term operational conditions, providing consistent performance even in challenging environments.

Additionally, the WCR-L expansion joint offers benefits such as vibration absorption, noise reduction, and simplified maintenance. By isolating the pipeline from external stresses, it reduces wear on pumps, valves, and other equipment, contributing to overall system reliability and efficiency. Its design adheres to international standards for pressure, flexibility, and durability, making it suitable for both domestic and export applications.

Overall, the WCR-L Type Anti-Settlement Winding Rubber Expansion Joint represents a cost-effective and reliable solution for pipeline systems that require long-term stability, flexibility, and protection against settlement-induced deformation.

The WCR-L Type Anti-Settlement Winding Rubber Expansion Joint is highly versatile and widely adopted across a range of industries due to its ability to accommodate movements, vibrations, and differential settlement. Its applications span municipal infrastructure, industrial pipelines, and commercial systems where both flexibility and durability are critical.

In municipal water supply and drainage systems, WCR-L expansion joints compensate for ground settlement, pipeline shifts, and thermal expansion. Many urban water networks run through areas with variable soil conditions, requiring joints that can absorb differential movements to prevent leakage and pipeline rupture. These joints are particularly beneficial for large-diameter pipelines that traverse soft soil or reclaimed land, as they reduce the risk of structural stress and operational downtime.

In HVAC (Heating, Ventilation, and Air Conditioning) systems, WCR-L joints absorb vibrations generated by pumps, fans, and compressors. Commercial buildings, hospitals, and industrial facilities often have complex HVAC networks where vibration transmission can cause noise issues, mechanical fatigue, or damage to connected components. By isolating vibrations, WCR-L joints ensure quieter operation, reduce maintenance needs, and prolong the lifespan of system components.

For industrial process pipelines, including chemical plants, refineries, and power stations, these joints accommodate thermal expansion, pressure fluctuations, and mechanical vibrations. Their ability to maintain alignment and flexibility under extreme conditions makes them suitable for high-temperature, high-pressure, and corrosive environments. The reinforced winding structure ensures the joint can withstand repeated cycles of expansion and contraction without compromising performance.

In power generation facilities, such as thermal, hydro, or combined-cycle plants, WCR-L expansion joints are used to connect water, steam, or cooling pipelines. These systems often experience significant thermal cycling and mechanical vibration, making flexible joints essential to prevent stress accumulation and equipment fatigue.

In municipal engineering projects, including sewage, drainage, and stormwater pipelines, WCR-L joints reduce the impact of settlement, vibration, and external loading. They are effective in situations where pipes pass beneath roads, bridges, or buildings, absorbing movement and preventing pipeline misalignment or leakage.

Overall, the WCR-L Type Anti-Settlement Winding Rubber Expansion Joint is valued for its adaptability across different pipeline materials, sizes, and operating conditions. Its ability to absorb stress, vibration, and movement makes it an indispensable component in modern infrastructure and industrial systems where reliability, longevity, and safety are critical.

The anti-settlement feature of the WCR-L Type Winding Rubber Expansion Joint is engineered to address one of the most common challenges in pipeline systems: uneven foundation settlement. Over time, soil consolidation, seismic activity, or construction-induced disturbances can cause pipelines to shift or tilt, generating stress concentrations at rigid joints that may lead to cracks, leaks, or failure. The WCR-L expansion joint prevents such issues through its reinforced winding structure and flexible rubber body.

The joint is constructed with high-strength fibers or steel cords embedded within the rubber, which restrict excessive axial compression or elongation while allowing controlled flexibility. This reinforcement ensures that when one section of the pipeline settles differently from another, the joint absorbs and compensates for the displacement, maintaining proper alignment and reducing stress on the connected piping. Its design also permits angular and lateral movements, allowing the pipeline to adapt to complex geometries or uneven supports without compromising structural integrity.

In addition to mechanical reinforcement, the rubber material itself contributes to anti-settlement performance. High-quality EPDM, NBR, or other specialized elastomers provide elasticity, fatigue resistance, and long-term durability, even under fluctuating temperatures and pressures. The combination of flexible rubber and reinforced winding allows the joint to maintain its shape and performance over thousands of operational cycles, providing a long service life with minimal maintenance.

The anti-settlement function also improves overall system reliability. By preventing misalignment and reducing localized stress, WCR-L joints protect valves, pumps, and other sensitive equipment from excessive vibration and mechanical load. This is particularly important in industrial pipelines where downtime can be costly, or in municipal systems where leakage can disrupt critical services.

Furthermore, the anti-settlement design facilitates safer installation. The joint’s flexibility allows for minor adjustments during alignment, reducing the need for exact tolerances and compensating for slight ground or structural irregularities. This adaptability ensures that the pipeline can accommodate gradual settlement over time without requiring extensive modification or repair.

In summary, the WCR-L expansion joint’s anti-settlement capability is achieved through a combination of reinforced winding, high-quality elastic materials, and flexible design, ensuring long-term pipeline stability, reduced maintenance, and protection of connected equipment. Its application is critical in any system where differential settlement, vibration, or thermal movement may otherwise compromise structural integrity or operational reliability.

The WCR-L Type Anti-Settlement Winding Rubber Expansion Joint is engineered to operate under a variety of pressure and temperature conditions, making it suitable for medium-pressure pipeline systems across industrial, municipal, and commercial applications. Typically, these joints are designed to withstand operating pressures up to 1.6 MPa (16 bar), although custom versions can be manufactured to meet higher pressure requirements based on specific project needs.

The temperature resistance of the WCR-L expansion joint largely depends on the rubber material used. EPDM rubber joints are suitable for temperatures ranging from -40°C to 120°C, while NBR (nitrile butadiene rubber) joints typically operate between -30°C and 90°C. For specialized applications, such as steam pipelines or chemical processing, the joints can be fabricated from heat-resistant or chemical-resistant elastomers to meet extreme conditions.

Pressure and temperature resilience are critical to the joint’s functionality. Pipelines often experience thermal expansion, pressure surges, and fluctuations in fluid flow. The WCR-L expansion joint absorbs these stresses, preventing damage to the pipeline system. Its reinforced winding structure enhances axial, lateral, and angular load-bearing capacity, ensuring stability even under fluctuating conditions.

In addition to standard operating ranges, the joint maintains performance during transient events, such as sudden pressure spikes or rapid temperature changes. The combination of elastic rubber and embedded reinforcement allows the joint to return to its original shape without permanent deformation, ensuring long-term reliability.

Custom designs are available for pipelines operating under extreme conditions, including high-temperature steam, corrosive fluids, or high-pressure industrial applications. Engineers can specify rubber grades, wall thicknesses, and reinforcement types to match the precise operating environment, ensuring safety, compliance with standards, and extended service life.

Overall, the WCR-L Type Anti-Settlement Winding Rubber Expansion Joint provides a robust solution for pipelines that must accommodate thermal expansion, mechanical vibration, and uneven settlement, while maintaining integrity under a wide range of pressure and temperature conditions. Its versatility, durability, and reliability make it a preferred choice for both standard and specialized pipeline systems.

Proper installation of the WCR-L Type Anti-Settlement Winding Rubber Expansion Joint is essential to maximize its performance, longevity, and protective capabilities. The joint is designed with flanged ends for straightforward integration into pipeline systems. Installation involves aligning the joint with the pipeline axis, securing the flanges with appropriate bolts and gaskets, and ensuring that no pre-compression or pre-tension is imposed on the rubber body during assembly.

Before installation, the pipeline should be supported adequately to prevent sagging or misalignment, and the joint must be positioned so that it can move freely within its designed expansion and contraction limits. Allowing for sufficient space on either side ensures that the joint can absorb axial, lateral, and angular movements without overstressing the rubber or reinforcement.

During the installation process, care should be taken to avoid twisting the joint or applying uneven force, as this can compromise the reinforcement and reduce service life. The surrounding environment should be inspected for sharp edges or protrusions that could damage the rubber surface.

Once installed, the WCR-L expansion joint functions to absorb vibrations from pumps, compressors, or fluid flow, as well as to compensate for differential settlement and thermal expansion. Its flexibility reduces stress on connected equipment and protects the overall pipeline system from leakage, fatigue, or misalignment.

Routine inspection after installation is recommended to ensure that the joint is properly aligned and that the flanges remain tight. Over time, minor adjustments may be necessary if the pipeline settles further, although the anti-settlement design minimizes the impact of such changes. The joint’s reinforced winding and high-quality rubber provide long-term reliability even in challenging operating environments.

Overall, careful installation combined with proper alignment, support, and inspection ensures that the WCR-L Type Anti-Settlement Winding Rubber Expansion Joint delivers optimal vibration absorption, movement compensation, and pipeline protection, making it a dependable choice for a wide range of applications.

Customization Options for Flanges and Single Bellow

| Option | Flange Material | Flange Standards | Sphere (Bellow) Material |

|---|---|---|---|

| 1 | Cast Iron | ANSI (American National) | NR (Natural Rubber) |

| 2 | Carbon Steel | DIN (German Standards) | NBR (Nitrile Butadiene Rubber) |

| 3 | Stainless Steel | JIS (Japanese Standards) | EPDM |

| 4 | Brass | BS (British Standard) | CR (Chloroprene) |

| 5 | Aluminum Alloy | Chemical Industry Standards | FKM (Fluoroelastomer) |

| 6 | PVC | Marine Standards | Silicone |

| 7 | Other Materials | Custom Non-Standard | PTFE Lining |

Daily Production Showcase from Factory

Advantages of WCR-L Type Anti-Settlement Winding Rubber Expansion Joint

The WCR-L Type Anti-Settlement Winding Rubber Expansion Joint offers a comprehensive range of benefits that make it an essential component in modern pipeline systems. Its advantages extend beyond simple flexibility, addressing multiple challenges such as differential settlement, vibration, thermal expansion, noise reduction, and maintenance optimization.

1. Effective Compensation for Pipeline Movement:

One of the most critical benefits of the WCR-L expansion joint is its ability to compensate for axial, lateral, and angular movements in pipelines. Pipelines in industrial and municipal systems are often subject to differential settlement due to soil consolidation, foundation shifts, or external construction activity. Rigid connections in such pipelines are prone to stress concentrations, which can cause cracks, leaks, or catastrophic failure. The WCR-L joint’s reinforced winding and elastic rubber structure allow it to absorb and distribute these movements effectively, maintaining pipeline alignment and integrity.

2. Anti-Settlement Performance:

The “anti-settlement” feature is a core advantage that differentiates the WCR-L joint from conventional rubber expansion joints. Its high-strength winding structure prevents excessive compression or elongation caused by uneven foundation settlement, ensuring that the pipeline remains stable over time. This is particularly important in municipal water supply, sewage systems, and industrial plants where uneven ground conditions are common. By mitigating settlement effects, the joint reduces the risk of mechanical failure, leakage, or costly downtime.

3. Vibration and Noise Reduction:

Industrial pipelines are frequently subjected to vibrations from pumps, compressors, motors, and fluid flow. These vibrations not only generate noise but also accelerate wear on valves, pumps, and other connected equipment. The WCR-L expansion joint’s flexible rubber body effectively absorbs and isolates vibrations, minimizing noise transmission and protecting equipment from fatigue and premature failure. In commercial buildings, hospitals, and high-precision industrial applications, this results in quieter operation and improved working conditions.

4. Durability and Fatigue Resistance:

Constructed from high-quality rubber materials such as EPDM or NBR and reinforced with winding fibers or steel cords, the WCR-L joint exhibits excellent durability and fatigue resistance. It can withstand thousands of expansion-contraction cycles, fluctuating pressures, and thermal variations without permanent deformation or performance degradation. This long service life ensures that maintenance costs are minimized and the reliability of the overall pipeline system is enhanced.

5. Protection of Connected Equipment:

By absorbing movement, vibration, and stress, the WCR-L expansion joint protects sensitive equipment such as pumps, valves, compressors, and heat exchangers from mechanical shock and stress-induced damage. This contributes to overall system longevity and reduces the frequency of repairs or replacements, which is particularly valuable in high-pressure, high-temperature, or continuous-operation industrial environments.

6. Installation Flexibility and Safety:

The WCR-L joint is designed for easy installation with flanged ends. Its flexible structure allows for minor alignment adjustments during assembly, reducing installation errors and the risk of stress concentrations. Once installed, the joint’s anti-settlement design ensures that pipelines can adapt to gradual ground settlement or thermal movement without intervention, maintaining operational safety and efficiency.

7. Versatile Applications:

This expansion joint is suitable for a wide range of industries and applications, including water supply and drainage, HVAC systems, industrial process pipelines, power plants, municipal engineering, and chemical plants. Its ability to accommodate thermal expansion, vibration, and ground movement makes it an indispensable solution for complex pipeline networks where reliability, safety, and durability are essential.

8. Cost Efficiency:

By reducing the risk of leaks, equipment failure, and maintenance downtime, the WCR-L expansion joint offers significant long-term cost savings. Its durability, low maintenance requirements, and ability to prevent stress-related damage to pipelines and equipment provide a strong return on investment for both municipal and industrial projects.

In summary, the WCR-L Type Anti-Settlement Winding Rubber Expansion Joint provides a unique combination of flexibility, anti-settlement stability, vibration absorption, noise reduction, equipment protection, and long-term durability. It is engineered to meet the demands of modern pipeline systems, ensuring operational reliability, safety, and cost-effective maintenance over its service life. This comprehensive set of benefits makes the WCR-L expansion joint a preferred choice for engineers, project planners, and facility managers seeking a dependable solution for pipeline movement and vibration challenges.