VBL/BDL BELL MOUNTS

Reliable Vibration Control, Unmatched Durability.

VBL/BDL BELL MOUNTS

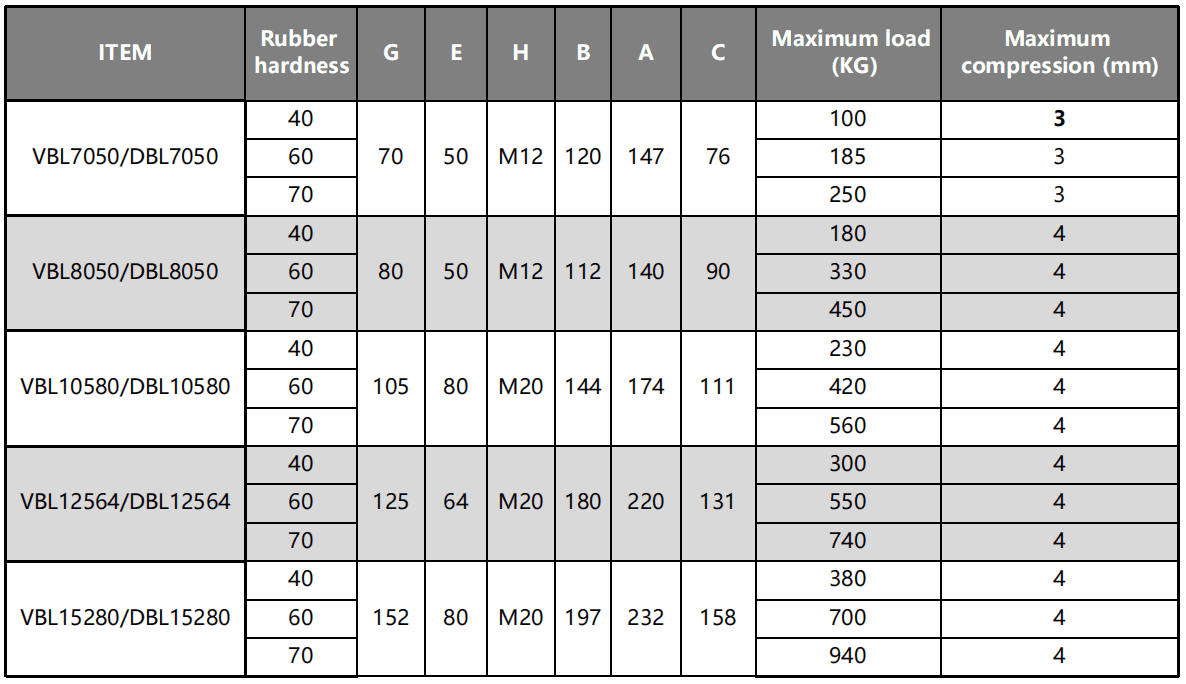

VBL/BDL Bell Mounts offer a wide range of load capacities to meet the needs of both light industrial equipment and heavy machinery. Standard models can typically support static and dynamic loads ranging from several tens of kilograms to multiple tons, depending on the mount’s size, rubber compound, and the thickness of metal components. For heavy-duty equipment, such as large generators, industrial compressors, or pump systems, the bell-shaped design ensures stability even under continuous operation and frequent vibration impacts, without significant compression set or fatigue cracking. Additionally, for specialized applications, manufacturers can provide custom sizes and material combinations to meet higher load requirements or challenging environmental conditions. Selecting the appropriate load capacity not only guarantees safe equipment operation but also extends service life, reduces maintenance frequency, and enhances overall industrial system reliability.

Choosing the right VBL/BDL Bell Mount requires careful consideration of multiple factors. First, the equipment’s weight and dimensions should be assessed to determine the mount’s load capacity, ensuring it can support the machinery and effectively absorb vibrations. Second, the type of vibration—including frequency, amplitude, and direction—needs to be analyzed, as it influences the choice of rubber hardness and elastomer design. Installation orientation is also crucial, as Bell Mounts can be installed horizontally or vertically, affecting vibration isolation performance. Environmental conditions, such as temperature fluctuations, humidity, chemical exposure, and presence of dust or particles, must also be considered, since they can affect rubber performance. If equipment parameters are complex or uncertain, it is recommended to provide detailed information to the supplier, including weight, dimensions, operating frequency, and installation conditions. Engineers can then recommend the most suitable model and provide technical drawings and calculations to ensure optimal vibration isolation, equipment stability, and prolonged service life.

Yes, VBL/BDL Bell Mounts are typically made from high-performance elastomers or specialized rubber compounds capable of maintaining stable performance across a wide temperature range. They can operate in cold environments as low as -40°C and in high-temperature industrial settings exceeding 120°C, depending on the selected material. In extreme temperatures, the elasticity and vibration-damping properties of the mount may vary slightly, but using appropriate material combinations, such as silicone rubber, fluororubber, or polyurethane elastomers, can significantly reduce performance degradation. Additionally, the metal components of the Bell Mounts are treated for corrosion resistance to ensure long-term durability in high humidity or chemical environments. For applications with significant temperature fluctuations, engineers can provide customized designs and material selections to guarantee consistent vibration absorption throughout the mount’s service life, protecting equipment from shock and noise.

Yes, VBL/BDL Bell Mounts can be customized according to specific customer requirements. Customization typically includes size, load capacity, rubber compound, and metal component design to ensure optimal performance in specific industrial equipment. For instance, for high-frequency vibrations or heavy-load machinery, manufacturers can use rubber or elastomer materials with different hardness levels and optimize the bell shape and wall thickness to enhance vibration absorption and longevity. For special environmental conditions, such as high temperatures, high humidity, chemical exposure, or cleanroom applications, specialized rubber compounds can be selected to ensure long-term stable performance. Customization may also include unique mounting interfaces or fastening methods to better fit equipment installation. Through customization, customers can obtain a vibration isolation solution tailored to their equipment, improving operational efficiency, reducing maintenance costs, and extending equipment service life—making it an ideal solution for complex industrial needs.

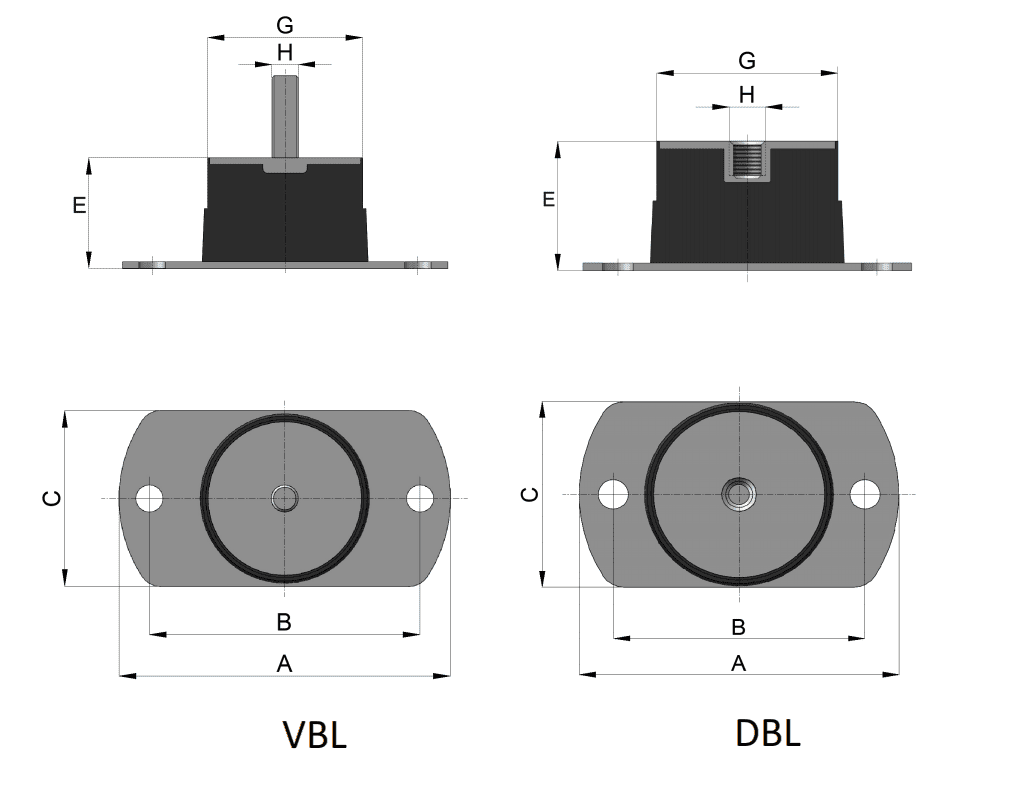

Installation Diagram of VBL/BDL BELL MOUNTS

Parameter Table of VBL/BDL BELL MOUNTS

If you like this VBL/BDL BELL MOUNTS but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]