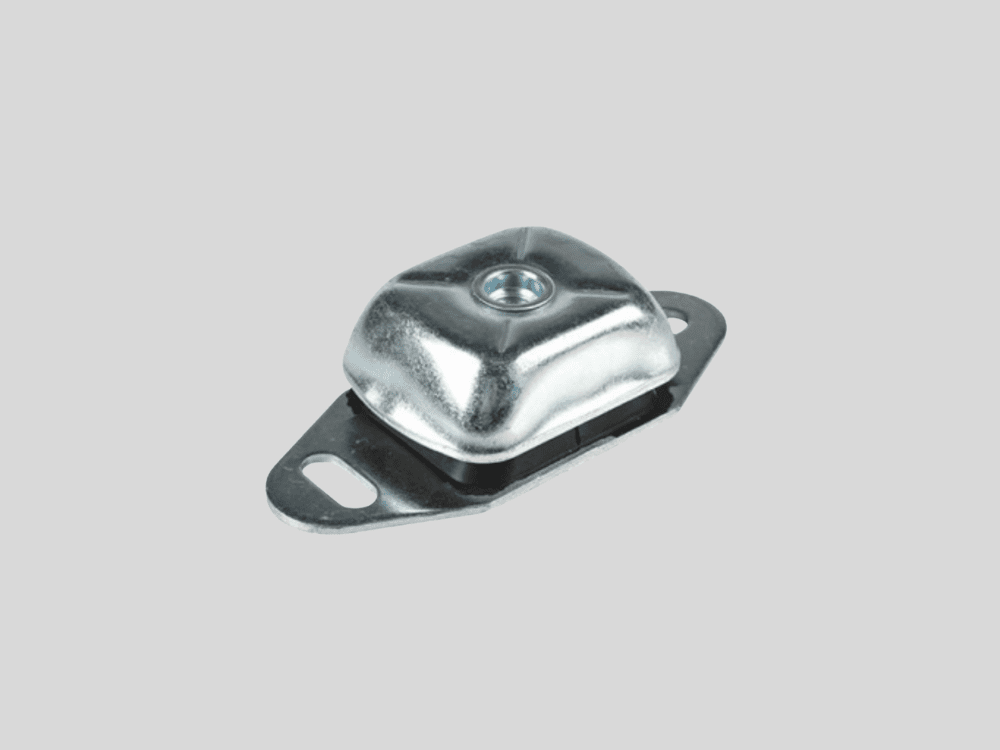

MARINE Bell Mounts

Smooth Sailing with Marine Bell Mounts – Vibration-Free Performance!

MARINE BELL MOUNTS

Marine Bell Mounts are high-performance vibration isolators specifically designed for marine equipment, primarily used to protect engines, generators, compressors, pumps, and other critical machinery on ships. In the marine environment, ship equipment is constantly exposed to vibrations and shocks from waves, hull movement, propulsion systems, and maneuvering. Without proper isolation, these vibrations can transmit through the hull to machinery, causing premature wear, mechanical failure, or even safety risks. Marine Bell Mounts effectively absorb these vibrations, dissipate the energy, and reduce the load transferred to equipment, ensuring the long-term stable operation of critical systems.

In addition, Marine Bell Mounts reduce operational noise, providing a more comfortable working environment for crew members. In commercial vessels, this improves operational efficiency and passenger experience, while in military or research ships, it ensures the stability and accuracy of sensitive instruments such as navigation systems and scientific equipment. Applications of Marine Bell Mounts are not limited to propulsion systems—they are widely used in pumping stations, compressed air systems, cooling systems, and more, ensuring the overall performance and reliability of the vessel.

Through scientific design and high-quality materials, Marine Bell Mounts deliver efficient vibration isolation across various ship types, including cargo ships, tankers, yachts, and naval vessels. They perform exceptionally in absorbing low- and high-frequency vibrations, handling dynamic loads, and resisting harsh marine environments, enabling ship machinery to operate smoothly under complex navigation conditions. Choosing Marine Bell Mounts is essential for protecting equipment longevity, improving vessel safety, and optimizing operational costs.

Marine Bell Mounts are manufactured using high-performance rubber and corrosion-resistant metals to ensure reliable vibration isolation in harsh marine environments. The rubber components are made from specially formulated natural or synthetic rubber, providing excellent elasticity, fatigue resistance, and aging resistance. This material effectively absorbs vibration energy while maintaining stable shape over long-term use. High-quality rubber also resists salt spray, humidity, UV radiation, and chemical exposure, which is critical for marine applications.

The metal components are typically made from stainless steel, galvanized steel, or corrosion-treated steel, providing mechanical strength and structural stability under continuous loads and marine exposure. The composite design of metal and rubber ensures that Marine Bell Mounts combine elasticity for vibration absorption with the load-bearing capacity to withstand shocks, maintaining smooth operation of engines, generators, or pumps under all conditions.

Marine Bell Mounts are also optimized for load type and vibration characteristics, with adjustable rubber hardness and metal thickness to accommodate varying equipment weight, vibration frequency, and installation space. By integrating material science with engineering design, these mounts isolate both low-frequency large vibrations and high-frequency micro-vibrations, extending equipment lifespan and reducing maintenance costs. High-quality construction ensures long-term performance, protecting equipment against harsh marine conditions while maintaining operational stability and reliability.

Marine Bell Mounts extend equipment life by absorbing and cushioning mechanical vibrations and shocks, significantly reducing stress and wear on critical components such as bearings, gears, shafts, and mounting brackets. During long-term vessel operation, engines, generators, and pumps are constantly exposed to vibrations and impacts. Without effective isolation, these vibrations accumulate, leading to structural fatigue, loosening components, and premature failure. Marine Bell Mounts dissipate this vibration energy and reduce impact loads transferred to equipment, ensuring stable operation even under high-load conditions.

Additionally, these mounts minimize micro-cracks and stress concentrations caused by vibration, preventing material fatigue and damage over time, which significantly extends the operational lifespan of machinery. For ship operators, installing Marine Bell Mounts reduces equipment failure rates, maintenance frequency, and associated costs while enhancing overall vessel efficiency. Furthermore, vibration control protects sensitive onboard instruments and electronic systems, ensuring reliable operation of navigation, communication, and monitoring devices, providing a safe, comfortable, and efficient sailing environment.

Marine Bell Mounts are engineered for marine applications, capable of withstanding saltwater corrosion, humidity, temperature fluctuations, and long-term dynamic loads. The rubber components are specially formulated to resist salt spray, UV radiation, moisture, and aging, maintaining elasticity and vibration isolation performance even after prolonged exposure to the marine environment. The metal components, treated for corrosion resistance or made from stainless steel, ensure structural integrity and mechanical strength under high humidity, saltwater, and intense vibration conditions.

The composite structure of Marine Bell Mounts allows them to handle dynamic loads and impacts generated during vessel operation, including wave impacts, operational vibrations, and lateral forces from steering. Their design provides effective isolation across both low-frequency large-amplitude vibrations and high-frequency micro-vibrations, protecting critical equipment for long-term reliable operation. Marine Bell Mounts are suitable for commercial, military, and research vessels, ensuring engines, generators, pumps, and sensitive instruments maintain performance and stability while reducing maintenance risks and extending equipment lifespan.

Marine Bell Mounts feature a modular design that simplifies installation across various marine equipment, requiring minimal tools for secure mounting and adjustment. During installation, the mount positions can be optimized based on equipment weight and vibration characteristics to achieve maximum vibration isolation. Maintenance is minimal, as high-quality rubber and corrosion-resistant metals ensure longevity even in humid and saltwater environments.

Over time, periodic inspections of bolt tightness and rubber integrity are sufficient, with no need for frequent replacements. Compared to traditional mechanical springs or metal supports, Marine Bell Mounts offer lower maintenance costs and ease of operation. Their stable vibration isolation performance protects equipment from damage, reduces maintenance frequency, and minimizes downtime, improving overall vessel operational efficiency.

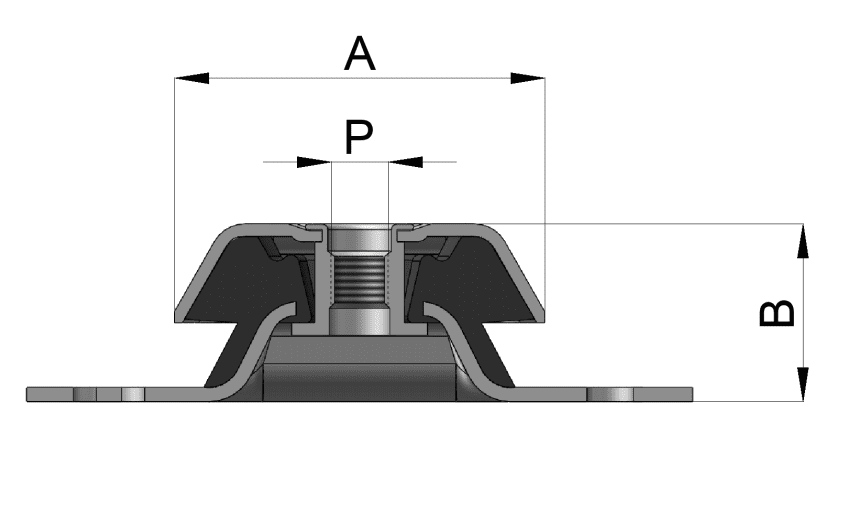

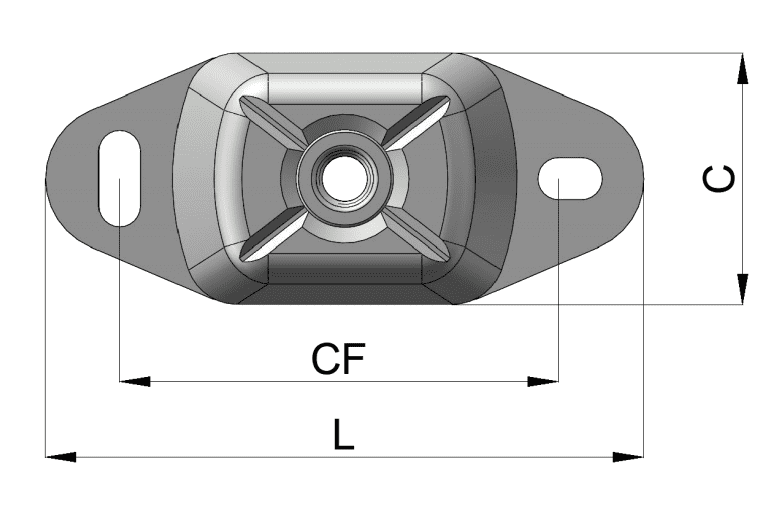

Installation Diagram of MARINE BELL MOUNTS

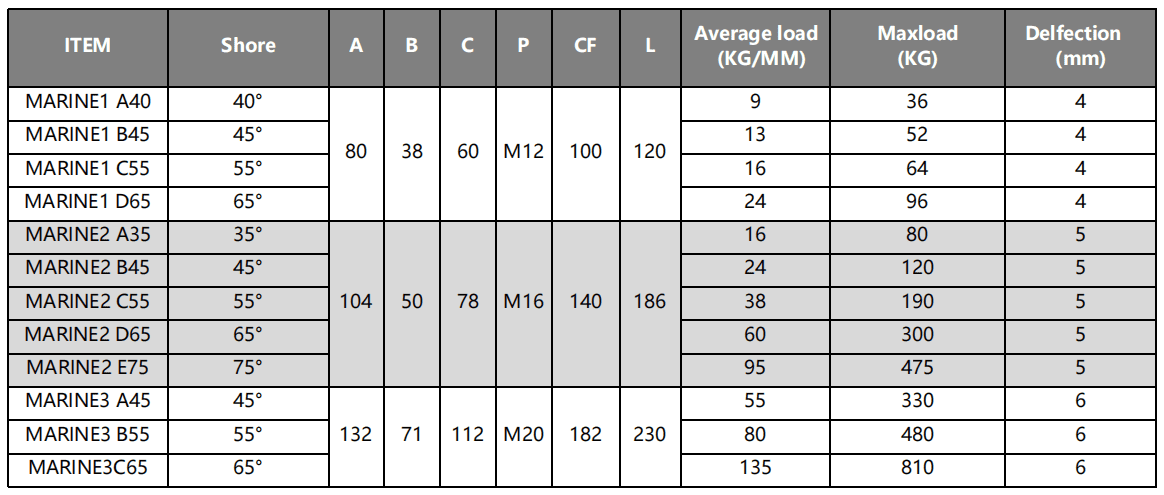

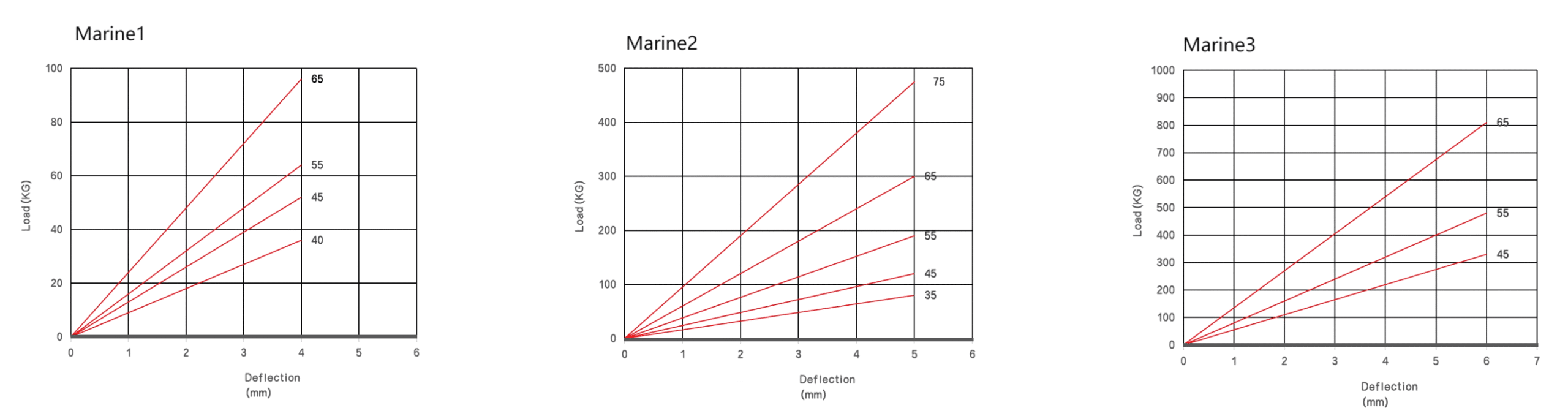

Parameter Table of MARINE BELL MOUNTS

If you like this MARINE BELL MOUNTS Bell Mounts but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]