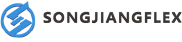

SW Type Rubber Buffer

Exceptional Care Provided by Highly Experienced Dental Professionals

SW Rubber Buffers for Plate Compactor

Rubber vibration isolators for compactor base plates serve as critical components that absorb, dampen, and isolate vibrations and shocks produced during compaction activities. These isolators are strategically positioned between the compactor’s vibrating mechanism (such as the exciter or engine) and the base plate to act as a buffer that mitigates the transmission of high-frequency vibrations and sudden shocks to the machine’s structural frame. By doing so, they reduce the risk of metal fatigue, structural cracks, and mechanical wear on essential parts, which could lead to premature failure. In addition to protecting the machine, these isolators significantly improve operator comfort by reducing the intensity of vibrations transmitted through the handle or chassis, thereby lowering operator fatigue and the risk of hand-arm vibration syndrome (HAVS). The result is improved operational efficiency, reduced downtime, and extended service life of the compactor.

Absolutely, rubber vibration isolators designed for compactor base plates are specifically engineered to tolerate the rigorous dynamic loading conditions typical in soil compaction tasks. These isolators must endure repetitive, high-magnitude impacts and continuous vibration cycles without losing their elastic properties or structural integrity. The materials used—commonly high-grade natural rubber, neoprene, or specially formulated synthetic elastomers—are selected for their excellent fatigue resistance, tear strength, and capacity to absorb shock energy. Moreover, many isolators incorporate metal inserts or bonding layers that reinforce mechanical strength and improve load distribution. This robust design prevents permanent deformation or failure, ensuring the isolators maintain consistent vibration attenuation performance over thousands of compaction cycles, even under harsh environmental conditions such as extreme temperatures, moisture, or exposure to oils and fuels.

Rubber vibration isolators greatly contribute to extending maintenance intervals and enhancing the overall durability of compaction equipment. By effectively absorbing and dissipating the shocks and vibrations generated during tamping operations, these isolators significantly reduce the mechanical stresses imposed on the base plate, engine mounts, hydraulic components, and other critical parts. This stress reduction prevents accelerated fatigue, cracking, and wear, which are common causes of unscheduled breakdowns. As a result, equipment can operate longer between maintenance cycles, minimizing downtime and reducing repair costs. Additionally, by stabilizing the vibration profile, isolators protect hydraulic seals and hoses from premature failure, further lowering the total cost of ownership. For operators and fleet managers, investing in high-quality rubber isolators is a strategic choice that ensures equipment reliability, operational efficiency, and safety in demanding construction and railway maintenance environments.

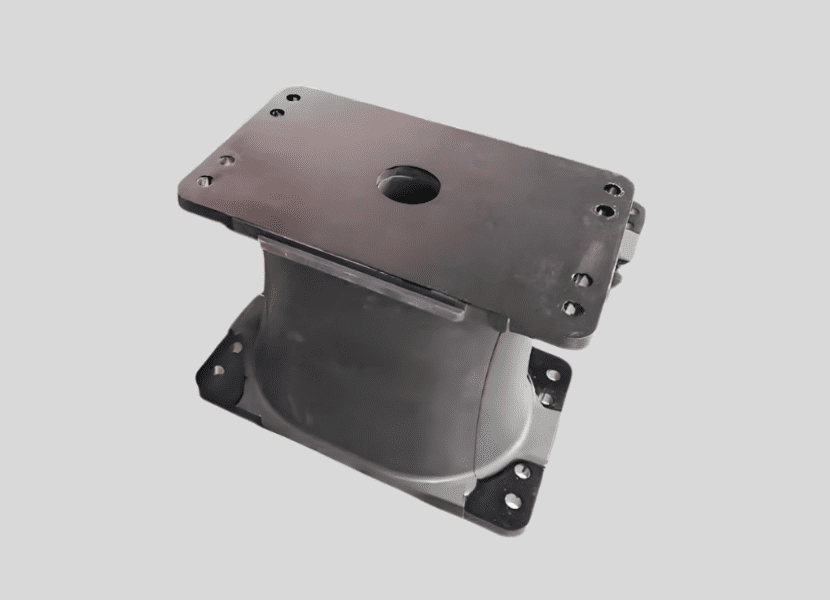

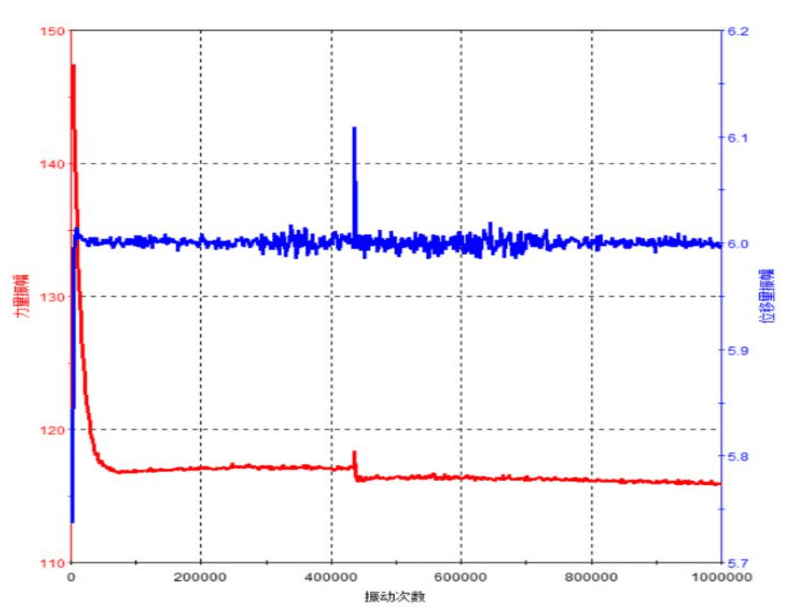

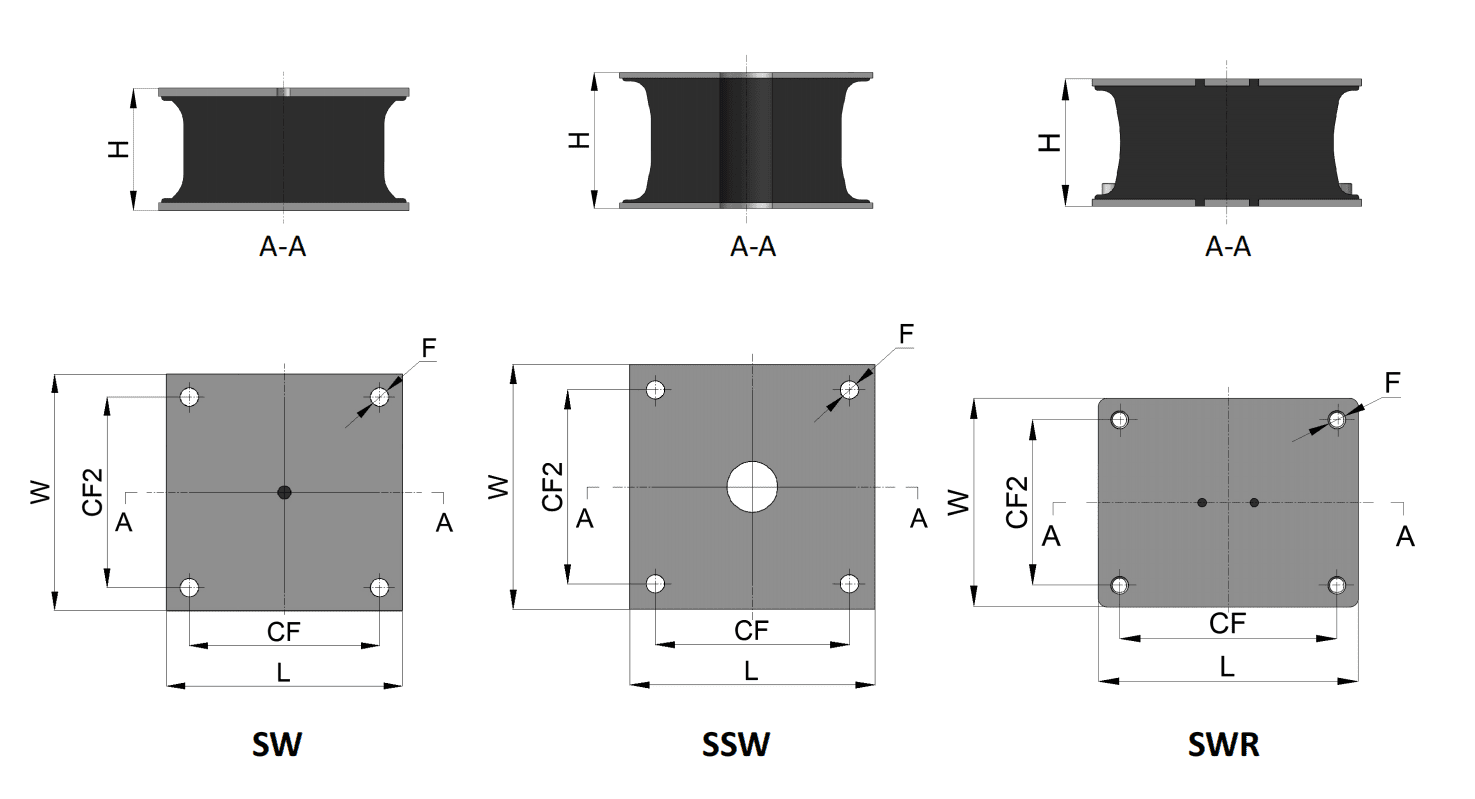

Testing Diagram of SW Rubber Buffers for Plate Compactor:

All of our rubber buffers undergo a series of rigorous quality inspections and performance tests before they leave the factory. By simulating various extreme working conditions and load scenarios, we continuously push our products to their limits to ensure that every buffer meets the highest standards of durability and reliability.

Our testing protocols cover aspects such as compression resistance, abrasion resistance, tear strength, and environmental adaptability to fundamentally guarantee stable and consistent product performance. We are committed to delivering products that not only comply with industry standards but also exceed customer expectations, ensuring exceptional vibration damping performance in real-world applications.

This enhances equipment safety and extends service life. We firmly believe that only through strict testing procedures and continuous technological improvements can we guarantee the outstanding quality of every product, providing our customers with a reliable, durable, and efficient experience.

It is this unwavering dedication to quality that has earned us the trust and support of a wide customer base.

Application Diagram of SW Rubber Buffers for Plate Compactor

Installation Diagram of SW Rubber Buffers for Plate Compactor

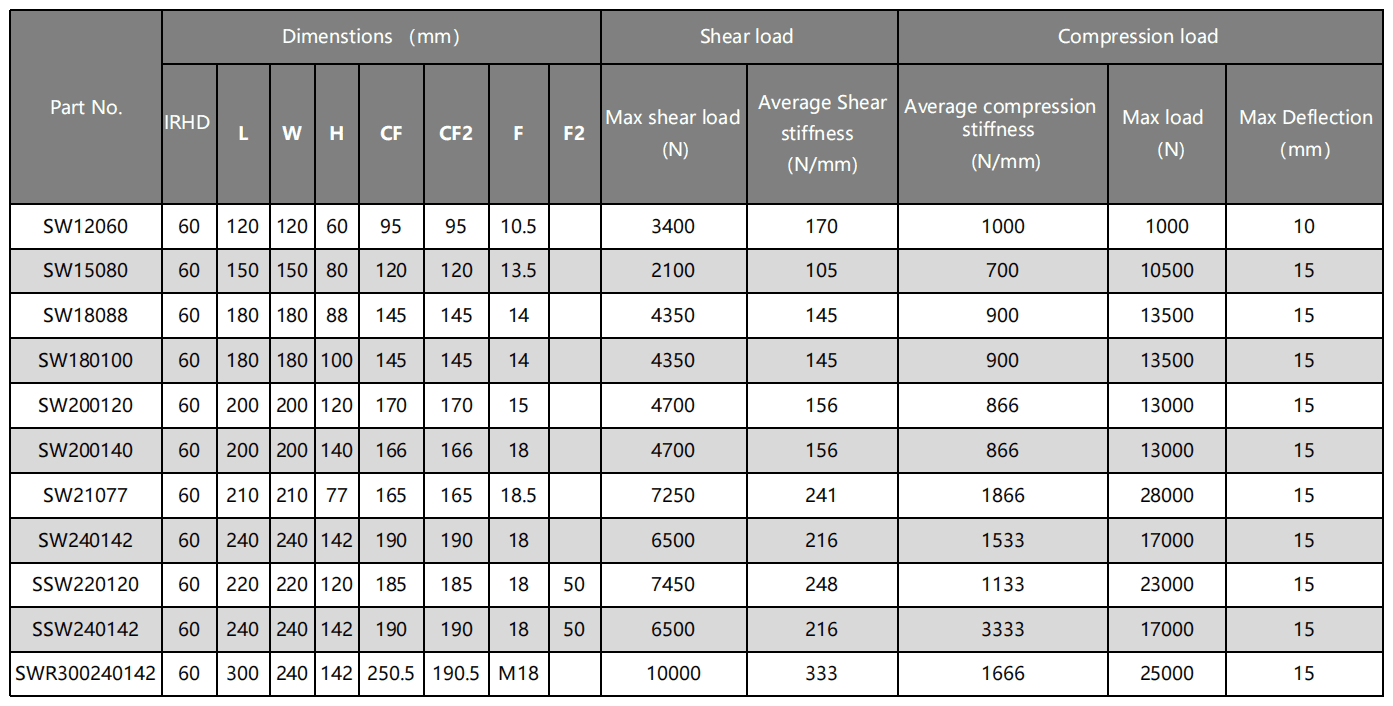

Parameter Table of SW Rubber Buffers for Plate Compactor

If you like this Rubber Buffers but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]