JNBC Type Cylindrical Mounts

Exceptional Care Provided by Highly Experienced Dental Professionals

JNBC Type Cylindrical Mounts

Rubber hardness, measured in Shore A, is one of the most critical parameters affecting the isolator’s dynamic behavior. It impacts the mount’s stiffness, natural frequency, and damping characteristics. Rubber compounds with lower hardness (e.g., 40–60 Shore A) provide greater flexibility, allowing more deflection and yielding a lower natural frequency. This makes them ideal for isolating low-frequency vibrations generated by equipment such as air-cooled condensers or low-speed motors.

Conversely, higher Shore A hardness (e.g., 70–90) results in greater load-bearing capacity and dimensional stability, suitable for heavy-duty equipment or systems with frequent load shifts, such as industrial compressors and generators. However, this comes at the cost of reduced vibration isolation performance, particularly at lower frequencies.

Additionally, ambient temperature fluctuations can alter the rubber’s effective hardness, which in turn changes its isolation properties. That’s why selecting the correct hardness requires consideration of several factors: equipment weight, operating frequency range, expected dynamic loads, and environmental conditions. Our engineering team offers material consultation and hardness analysis to help ensure the optimal balance between vibration control and mechanical support for your specific application.

Yes. JNBC cylindrical mounts are engineered to handle not only continuous harmonic vibrations but also dynamic and transient loads such as impacts, shocks, or sudden load changes. Many industrial machines experience frequent start/stop cycles or operate with unbalanced rotating components that generate unpredictable vibration profiles. JNBC mounts are designed for such scenarios.

Thanks to their elastomeric core and reinforced bonded construction, these mounts offer wideband vibration isolation and shock absorption capabilities. They can dissipate transient energy, reduce peak acceleration, and prevent resonance amplification. The mounts' multi-directional flexibility also helps mitigate stress concentrations and reduces mechanical fatigue on mounting structures over time.

In systems with fluctuating excitation frequencies—such as compressors with variable speed drives or equipment operating across different load phases—it's critical to select mounts based on dynamic analysis. This may include frequency response functions (FRF), modal testing, or finite element analysis (FEA). With the right selection and placement, JNBC mounts can significantly extend equipment life, improve noise control, and enhance operator safety.

Axial stiffness defines how the mount behaves under vertical loads, while radial stiffness determines its response to lateral or horizontal vibrations. Since many types of machinery generate multi-axis vibrations, the mount must perform effectively in both directions for comprehensive vibration control.

JNBC mounts are engineered with carefully calculated rubber volume, bonding area, and internal geometry to optimize the balance between axial and radial stiffness. For example, if radial stiffness is too low, equipment may sway, shift, or develop lateral instability during operation. On the other hand, insufficient axial stiffness can cause sagging or uneven load distribution, potentially affecting machine alignment and increasing stress on mounting interfaces.

Moreover, the axial-to-radial stiffness ratio influences the isolator's natural frequency and its resonance behavior. Proper tuning of this ratio allows the mount to perform consistently across a wider frequency spectrum, providing effective damping across different motion directions.

In high-performance or sensitive systems—such as precision HVAC units, control cabinets, or rotating machinery—selecting mounts with well-defined directional stiffness profiles is essential. Our technical team can help recommend optimal mounting configurations and support points based on your equipment's loading direction and dynamic behavior.

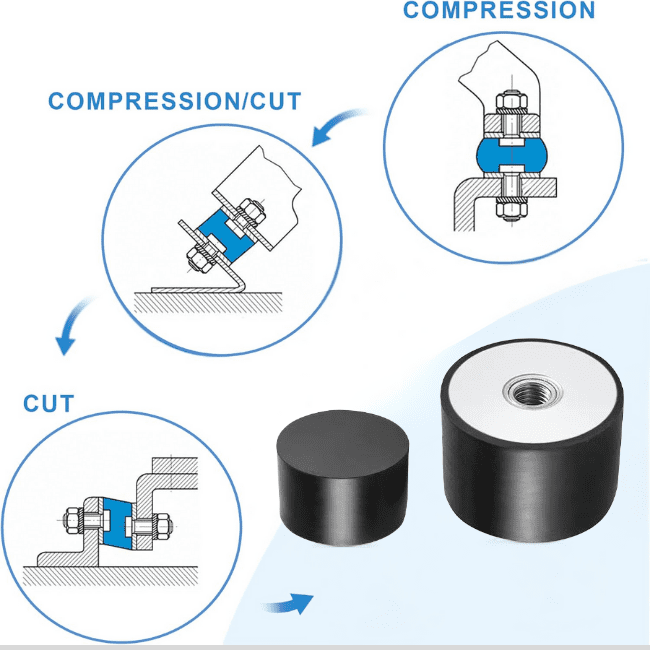

Installation Diagram Of JNBC Type Vibration Mount:

Installation Diagram of JNCC Cylindrical Vibration Mount

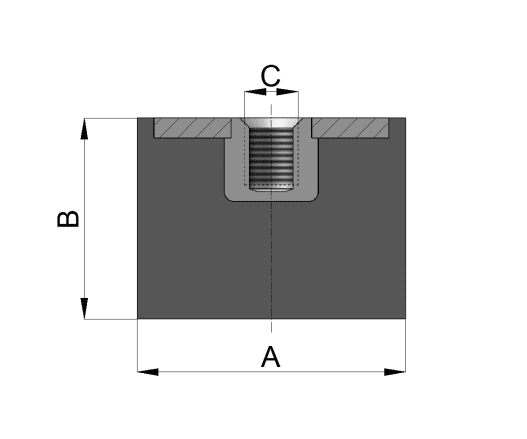

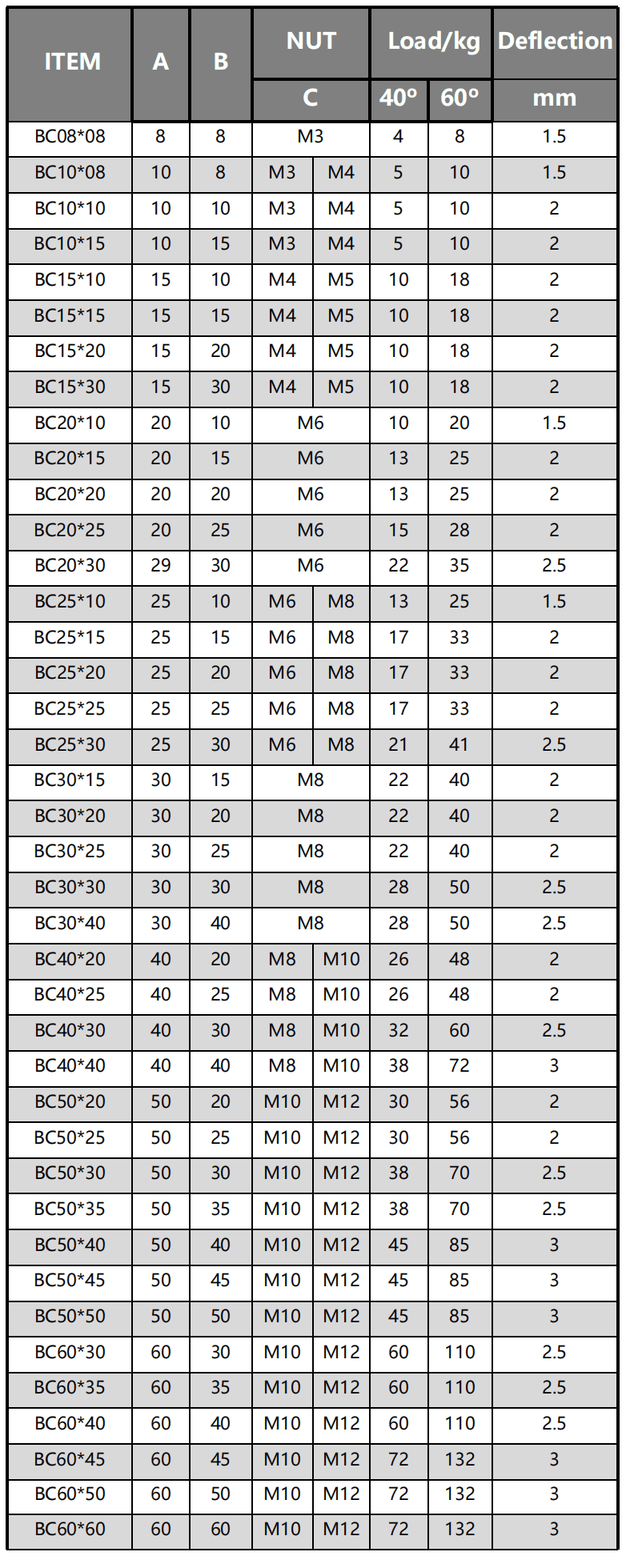

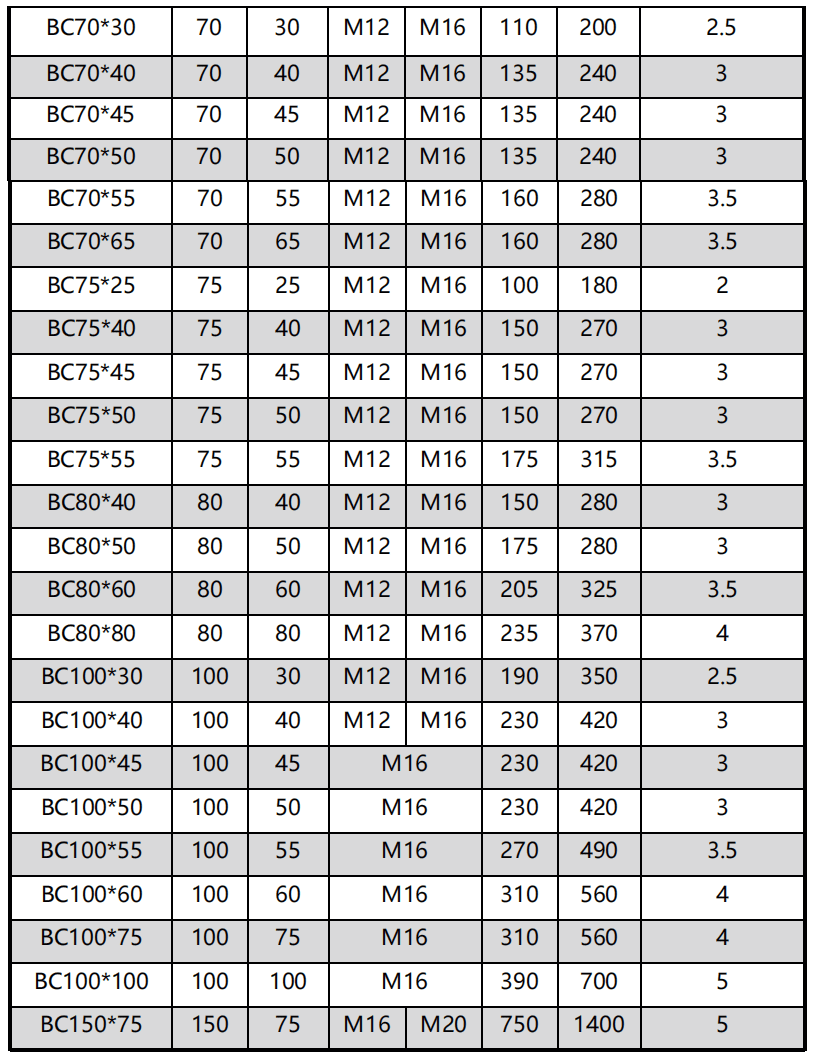

Parameter Table of JNBC Vibration mount

If you like this Cylindrical Vibration Mount but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]