GY Series Hydraulic Mount

Discover the CN Series Cone Mounts – Built for Stability and Strength

GY Series Hydraulic Mount

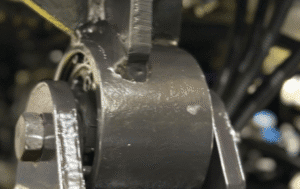

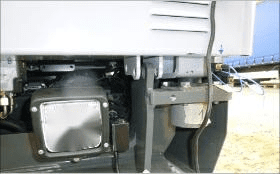

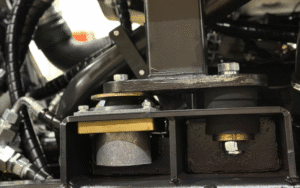

The GY Series Hydraulic Mount is a high-performance vibration isolator that combines a rubber spring with an internal hydraulic damping chamber. This dual-function design provides both elastic support and efficient motion control.

It works by allowing hydraulic fluid to flow through internal orifices during equipment movement, generating resistance (damping force). This dissipates energy while the rubber component absorbs vibration. The synergy between these elements allows the mount to isolate vibration and control excessive motion simultaneously—making it ideal for equipment with variable loads or frequent start-stop cycles.

The GY Series offers several unique advantages over conventional vibration isolators:

Dual isolation and damping functions in a single compact unit

Superior vibration isolation, especially in low to mid-frequency ranges

Excellent shock absorption during sudden machine start-ups or shutdowns

Extended equipment lifespan by reducing stress and fatigue on components

Noise reduction, improving both machine performance and work environment

Customizable performance, with options to tailor damping and stiffness levels

Durable construction, built with premium rubber and corrosion-resistant materials

Flexible mounting, suitable for vertical or horizontal installations

This makes it an ideal solution for OEMs, design engineers, and end-users seeking reliable and efficient vibration control.

This mount is widely used in industrial, marine, and HVAC applications that demand both vibration isolation and motion damping. Typical applications include:

Diesel generator sets

Water pumps (centrifugal, reciprocating, etc.)

Air compressors and refrigeration systems

Chillers, AHUs, and HVAC machinery

Industrial blowers and large axial fans

Marine engines and offshore equipment

Construction and mining machinery

Precision machinery with high sensitivity to vibrations

Its combination of stability, durability, and damping capacity makes it particularly effective in environments with fluctuating or dynamic loads.

The key difference lies in its integrated hydraulic damping system. Here's a comparison:

Rubber mounts only provide elastic support and are less effective at motion control.

Spring isolators offer excellent vibration isolation but often lack internal damping, leading to excessive movement unless additional dampers are installed.

GY Series hydraulic mounts combine both functions, ensuring balanced vibration control and movement limitation.

This makes them especially effective in applications where maintaining stability and safety under dynamic loads is critical.

Absolutely. Our team specializes in providing customized vibration isolation solutions, and the GY Series is designed with adaptability in mind. We offer:

Custom Shore A hardness levels to match your vibration frequency range

Adjustable hydraulic damping characteristics

Varied load capacities and mounting hole configurations

Optional surface treatments and anti-corrosion coatings

Tailor-made designs for space-constrained or high-temperature environments

Our engineers provide free design support, CAD models, and prototype development to help you find or create the perfect solution.

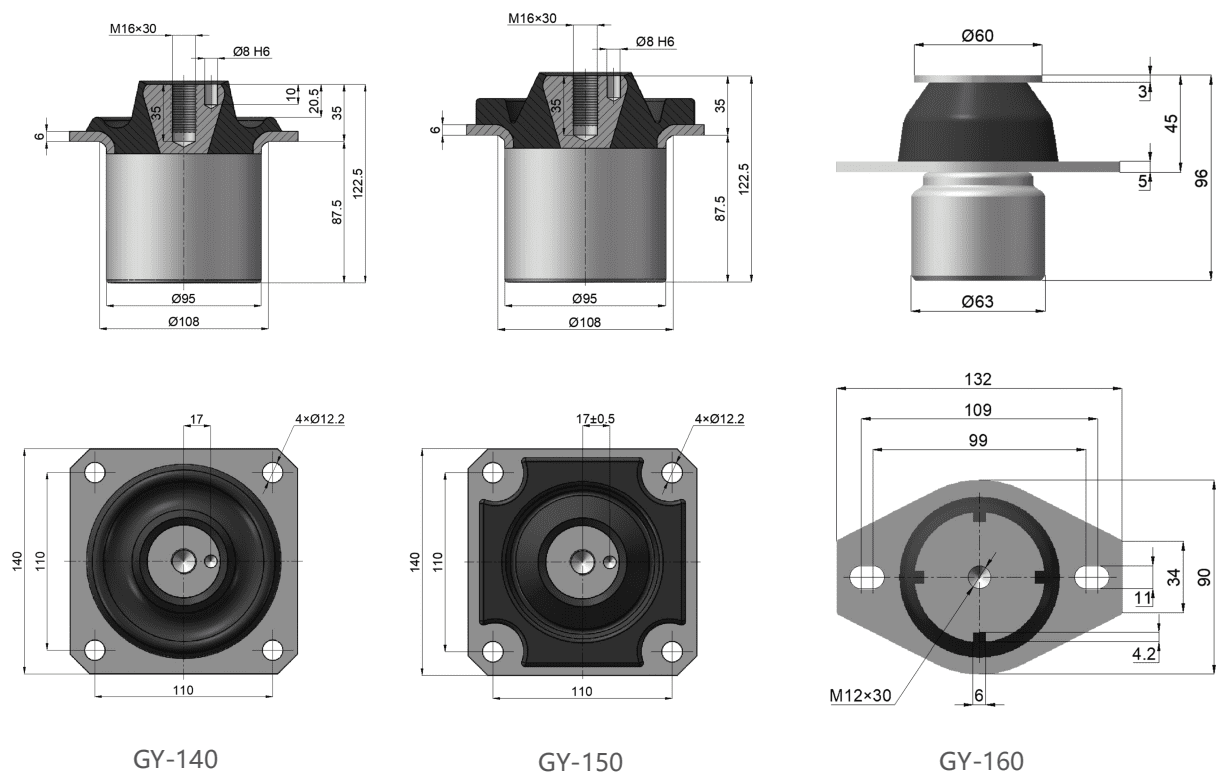

GY Series Hydraulic Mount Application Scenarios Diagram

The GY Series Hydraulic Mount is widely used across various industries due to its combined elastic and hydraulic damping functions. It is ideal for diesel generator sets, compressors, pumps, HVAC equipment such as AHUs and FCUs, as well as engineering machinery and precision instruments. Its ability to absorb shock, reduce vibration, and control displacement makes it a preferred solution for vibration isolation in both heavy-duty and sensitive applications.

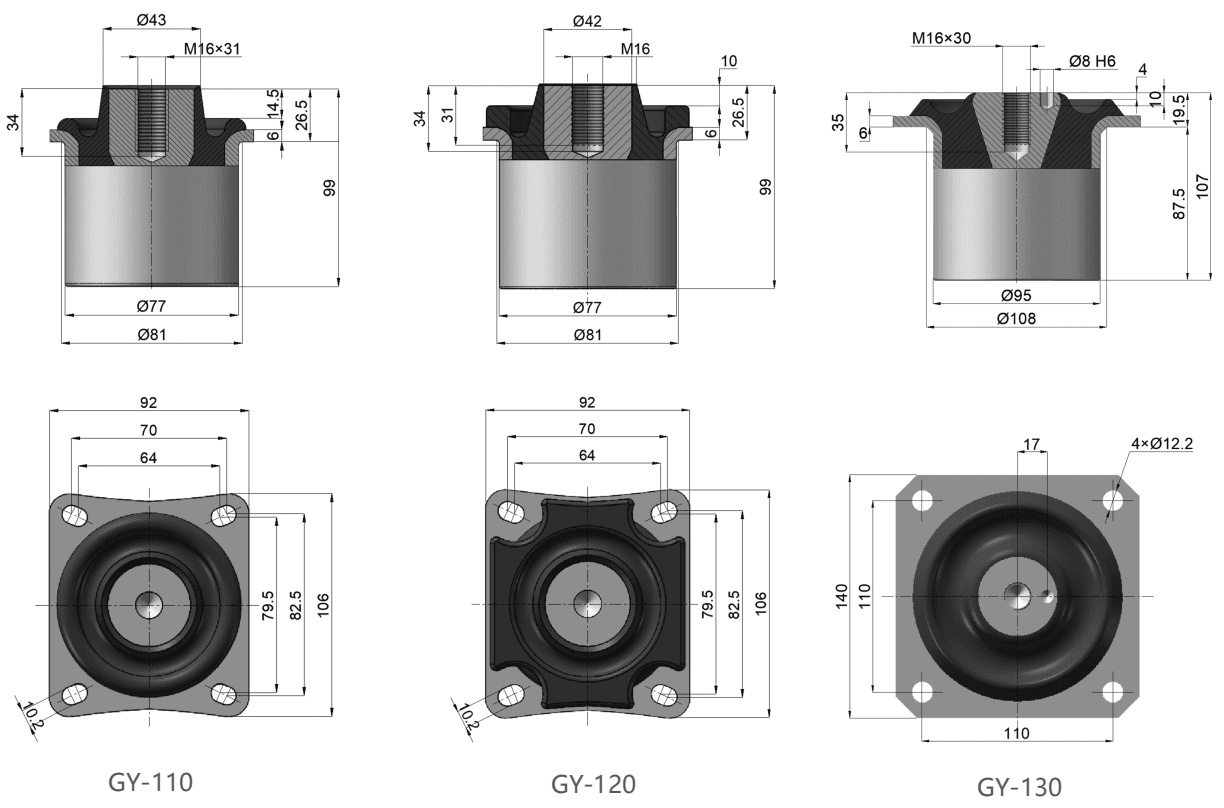

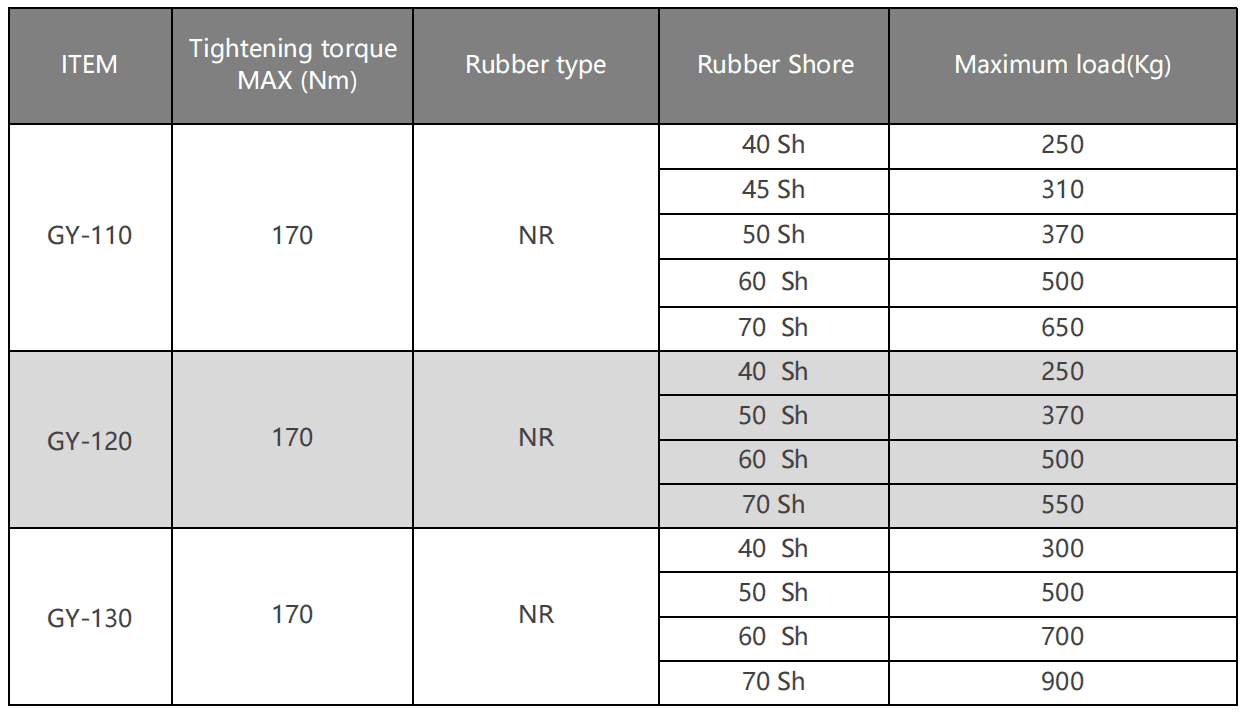

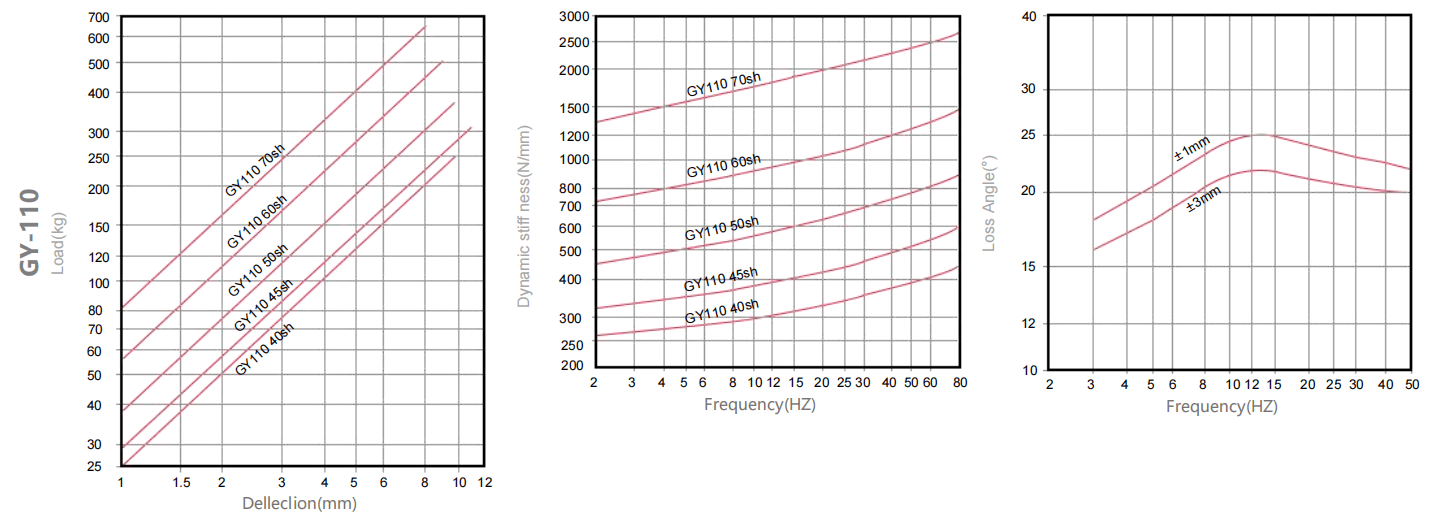

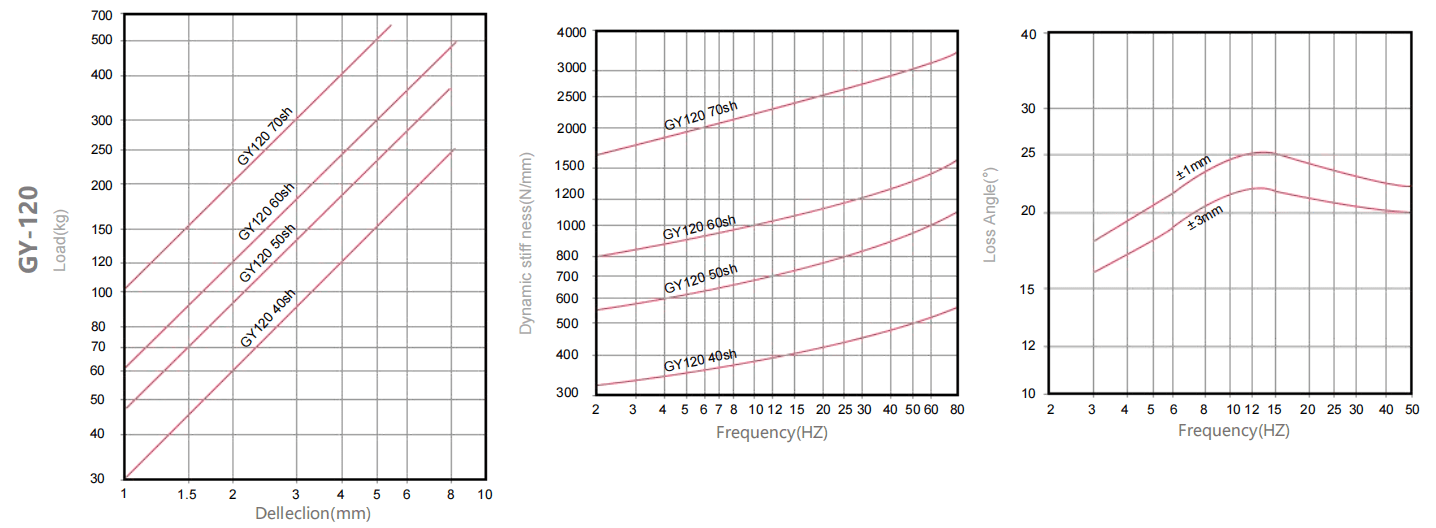

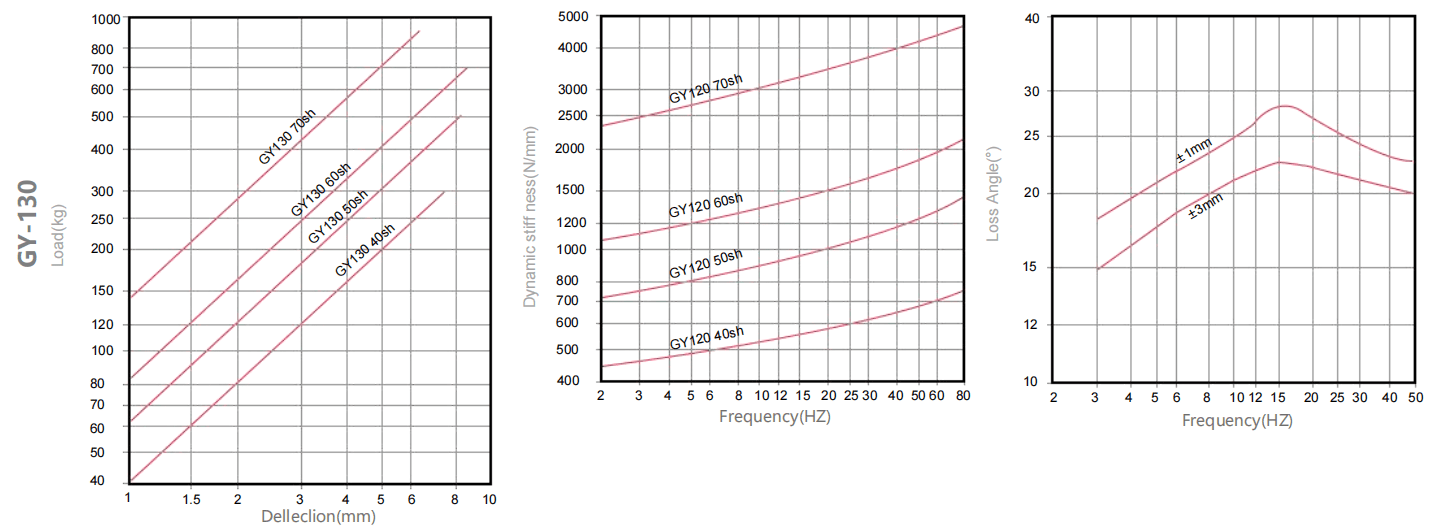

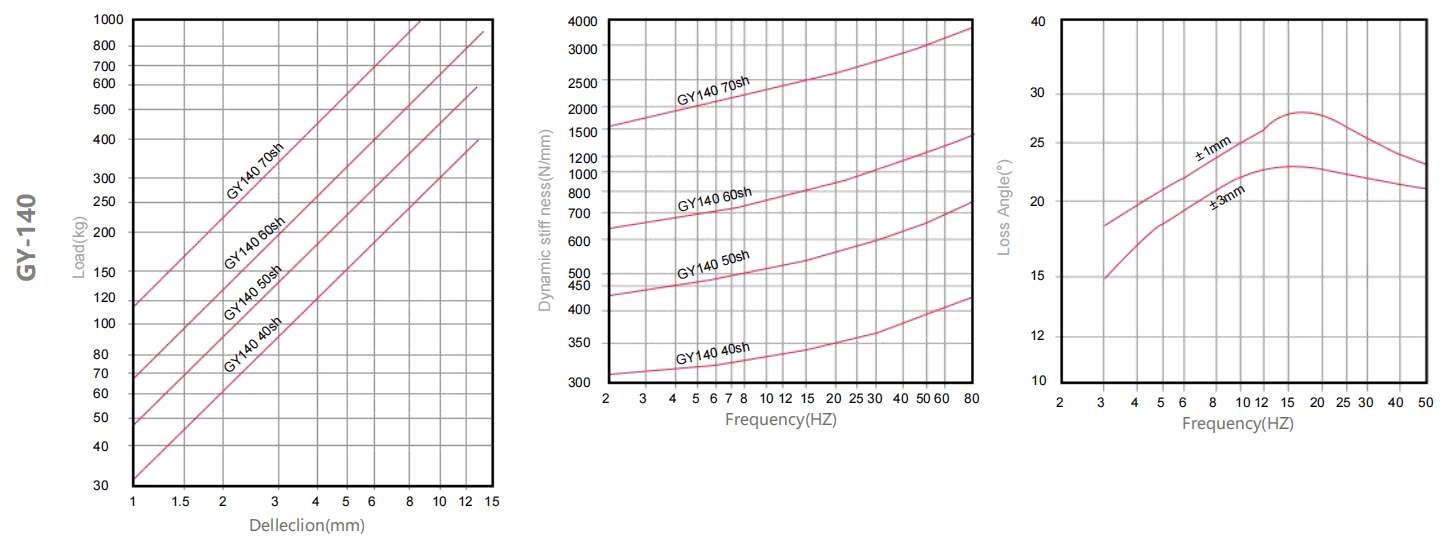

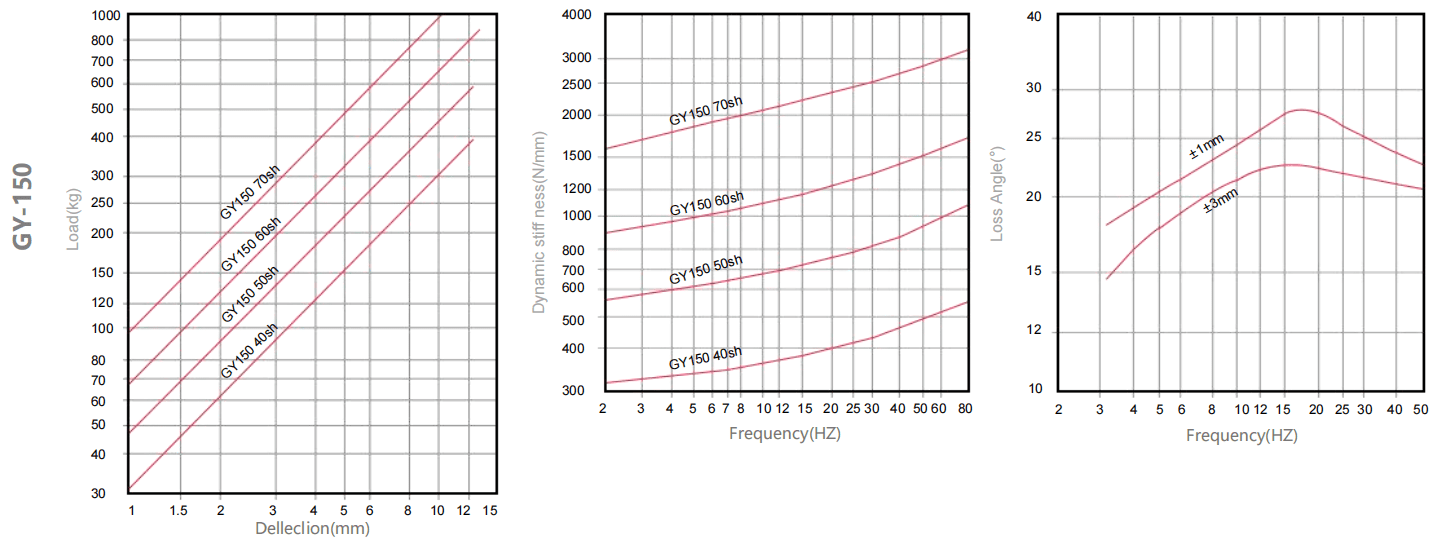

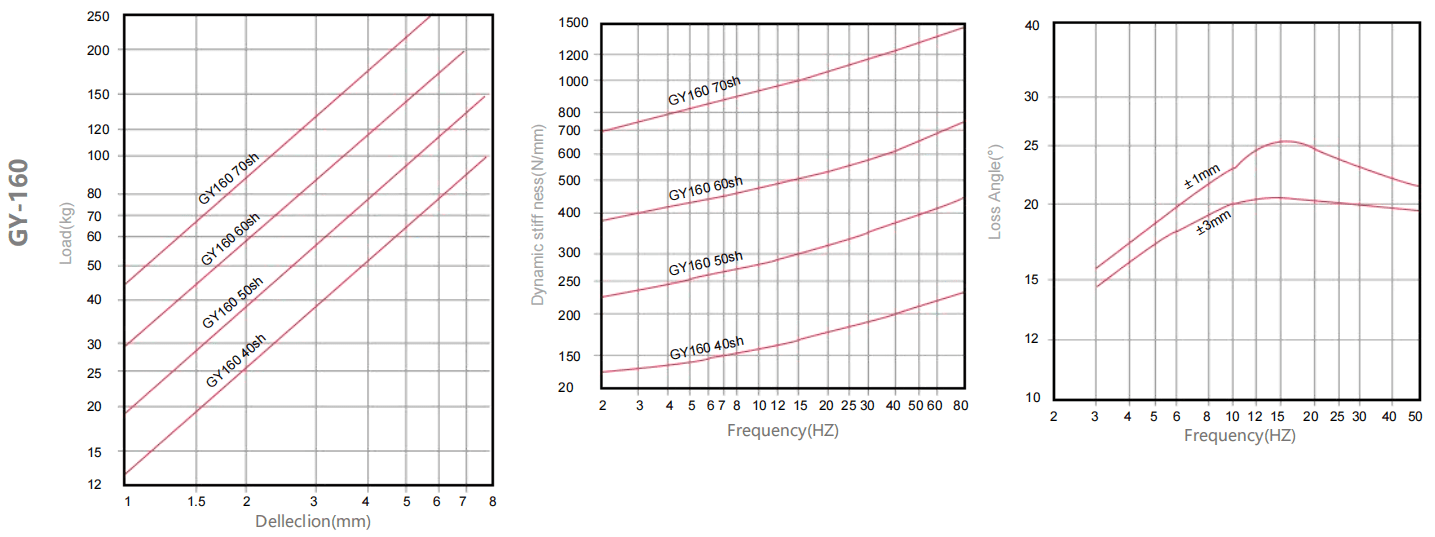

GY Series Hydraulic Mount Technical Specification Diagram

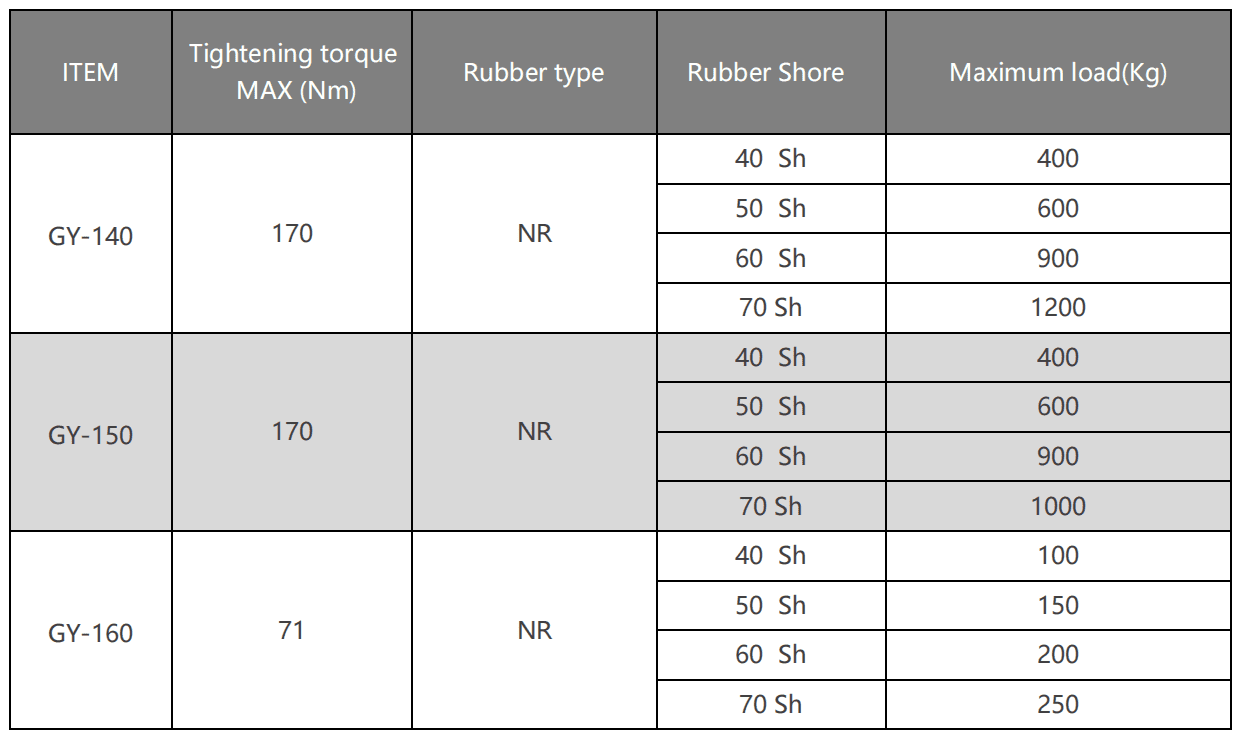

Elastic Response Curve

If you like this GY Series Hydraulic Mount but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]