JNDD Male-female type Cylindrical Mounts

Exceptional Care Provided by Highly Experienced Dental Professionals

JNDD Male-male type Cylindrical mounts

The JNDD male-female cylindrical mount adopts an advanced structural design featuring one male (external threaded) and one female (internal threaded) end. This hybrid configuration offers greater flexibility and alignment precision during installation, especially in scenarios where space is limited or mounting surfaces are uneven. Compared to traditional dual male or dual female mounts, this design provides a more adaptable solution.

The threaded connection allows for secure and tool-efficient mounting, avoiding the need for adhesives, welding, or multiple fasteners. It is particularly suitable for installations that require frequent maintenance or reassembly, such as electrical control cabinets, precision pump bases, and compressor platforms.

Furthermore, the male-female configuration improves shear resistance, maintaining reliable performance even under lateral loads—a key advantage over many conventional rubber mounts, which often struggle with horizontal displacement. This results in a more stable isolation system that effectively absorbs both vibration and shock, reduces wear on base structures, and prolongs equipment life.

The load capacity of the JNDD mount depends on several factors: rubber diameter, hardness (durometer), and working compression. For example, a typical model with M10 thread, 50 mm diameter, and 60A rubber hardness offers a static vertical load range of approximately 80–120 kg, with 3–5 mm compression. This enables effective vibration isolation within a frequency range of 10 Hz to 50 Hz.

This product is ideal for mid-to-low frequency vibration scenarios, and is widely used in:

HVAC systems (fans, chillers, air compressors)

Power and fluid equipment (pumps, small generators, screw compressors)

Automation and control devices (PLCs, frequency converters, control cabinets)

Light industrial machines (laser engravers, CNC marking, precision tables)

During selection, we recommend evaluating the total equipment weight, number of mounting points, dynamic frequency, and potential resonance. For advanced configurations, our engineering team can assist with vibration isolation design to avoid resonant frequencies and optimize performance.

In high-impact, high-amplitude, or heavy-load applications (e.g., stamping presses, large diesel engines), we recommend using spring isolators or air springs for better performance.

Yes. To meet the demands of harsh environments, we offer several corrosion-resistant variants of the JNDD mount:

Standard anti-corrosion version: Made with chloroprene rubber (CR) and zinc-plated steel components. This configuration provides reliable resistance to moisture, rust, and industrial oils, making it suitable for typical outdoor installations or factory environments.

Enhanced corrosion-resistant version: Designed for use in marine environments, near chemical pipelines, or coastal regions. These versions use SUS304 or SUS316 stainless steel threaded parts combined with EPDM (ozone/acid/alkali-resistant) or FKM (fluoro rubber for high-temperature and chemical resistance), ensuring long-term performance even under salt spray, oil mist, or acidic vapors.

Protective coatings available: For extra protection, optional coatings such as PTFE (Teflon), powder coating, or anodizing can be applied to the metal parts. Rubber sections can also be reinforced with anti-delamination structures to withstand frequent vibration and harsh operation cycles.

All materials used in the JNDD series can comply with RoHS, REACH, and PAHs environmental regulations, making them suitable for export to markets with strict ecological standards, including Europe and North America.

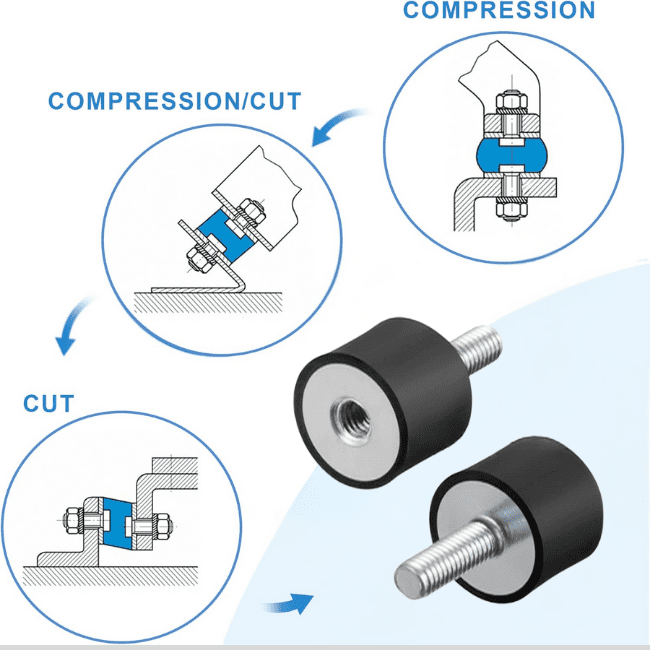

Installation diagram of JNDD male-male type vibration mount:

Installation diagram of JNDD male-male type vibration mount:

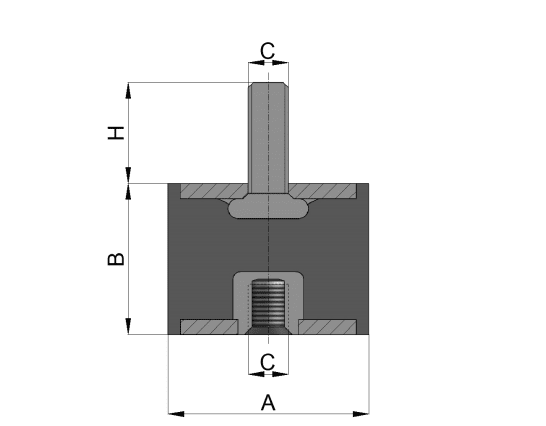

Installation Diagram of JNDD Cylindrical Vibration Mount

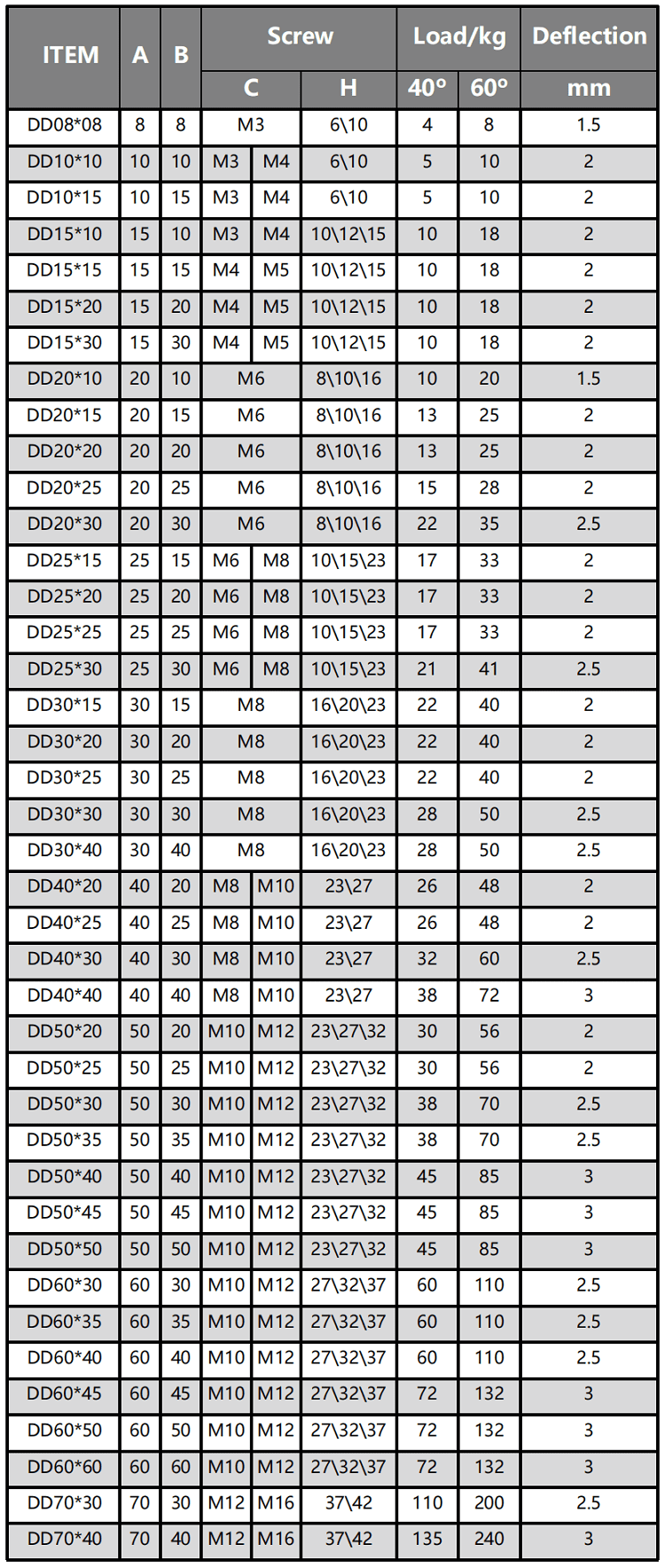

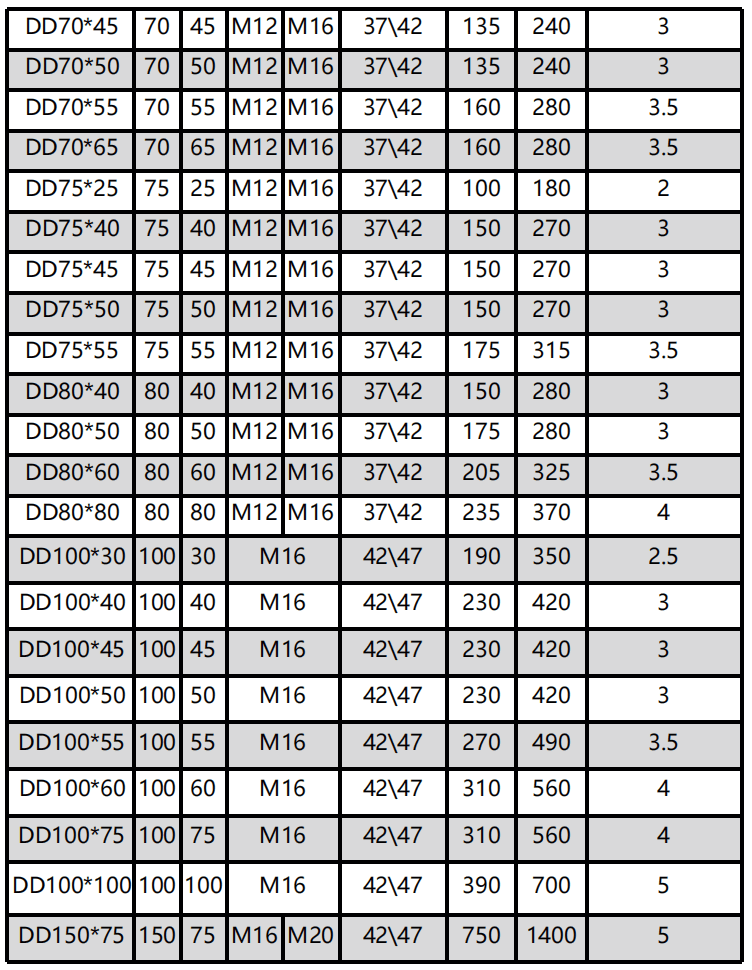

Parameter Table of JNDD Vibration mount

If you like this Cylindrical Vibration Mount but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]