TEE Series Multi-Layer Antivibration Dampers

Exceptional Care Provided by Highly Experienced Dental Professionals

TEE Series Multi-Layer Antivibration Dampers

The TEE Series antivibration dampers are primarily designed for heavy machinery in industrial sectors where stringent vibration control and impact cushioning are required. Their design thoroughly considers the diverse vibration frequencies and impact intensities generated during equipment operation, making them particularly suitable for dynamic loads and complex working conditions. Typical applications include hydraulic breakers, which generate strong impacts and high-frequency vibrations during construction and mining activities; the TEE dampers effectively protect the machine structure and ensure operator safety. Vibratory feeders are another common application, where stable vibration support is essential for precise feeding and prolonged equipment life. Additionally, metal forging equipment produces intense impacts and vibrations during the forming process, and the TEE series dampers help reduce vibration transmission and improve production efficiency. Construction platforms and concrete vibrators also rely on high-performance dampers due to harsh environments and heavy loads. In summary, with their multi-layer structure and excellent damping performance, the TEE series serve as crucial components to maintain stable operation and extend the lifespan of industrial machinery under harsh conditions.

The TEE Series dampers not only provide excellent vibration isolation but also significantly reduce the impact noise generated during equipment operation. Their core material is a high-damping rubber capable of converting mechanical vibration energy into heat, effectively absorbing vibration waves and preventing their transmission through the equipment structure. The multi-layer steel plate sandwich design enhances the damper’s rigidity and load-bearing capacity, while also dispersing impact forces along the vibration path, preventing resonance and noise spikes caused by concentrated impacts. Especially in equipment with frequent impacts, such as hydraulic breakers or vibratory screens, the TEE series smoothens the impact waveform and reduces vibration peaks, greatly lowering structural noise. This not only improves workplace comfort and safety but also decreases fatigue damage and maintenance frequency, thereby substantially enhancing overall equipment efficiency and economic benefits.

The TEE Series antivibration dampers are specifically designed to withstand a variety of complex and harsh working conditions, including outdoor use and highly corrosive environments. First, in terms of material selection, the TEE dampers utilize a specially formulated rubber compound with excellent weather resistance, capable of withstanding ultraviolet (UV) radiation, ozone exposure, and wide temperature fluctuations. This ensures that even when exposed to direct sunlight in open-pit mines, coastal areas, or high-temperature mechanical rooms, the rubber maintains its elasticity and vibration damping properties without cracking, hardening, or degrading over time.

Furthermore, to guarantee the overall durability of the structure, the internal multi-layer steel plates undergo rigorous anti-corrosion treatments such as hot-dip galvanizing, electrophoretic coating, or anti-rust painting. These treatments effectively protect the steel plates from rusting and oxidation in humid, dusty, or chemically aggressive environments.

Especially in environments like mining sites, marine engineering, and construction zones, equipment not only endures heavy mechanical loads but also faces prolonged exposure to rain, salt spray, and abrasive sediments. Thanks to its combined material advantages and precise manufacturing process, the TEE damper maintains structural stability and vibration isolation performance, even after years of outdoor use, continuing to provide reliable functionality and safety. Moreover, its design carefully considers the risks of moisture and dust ingress, ensuring a tight bond between the rubber layers and steel plates to prevent accelerated internal corrosion.

In summary, the TEE Series antivibration dampers are not only suitable for outdoor operations but also excel under highly corrosive conditions, making them an ideal choice for industrial equipment requiring dependable vibration protection in demanding environments.

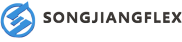

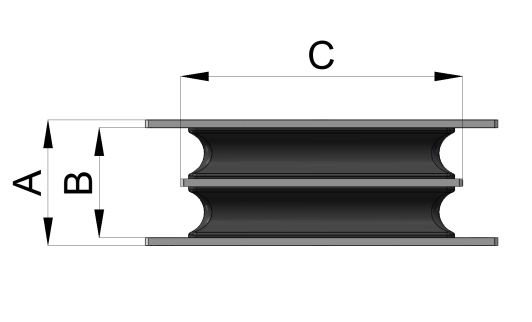

Installation Diagram of TEE Series Multi-Layer Antivibration Dampers

Parameter Table of TEE Series Multi-Layer Antivibration Dampers

If you like this Antivibration Dampers but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]