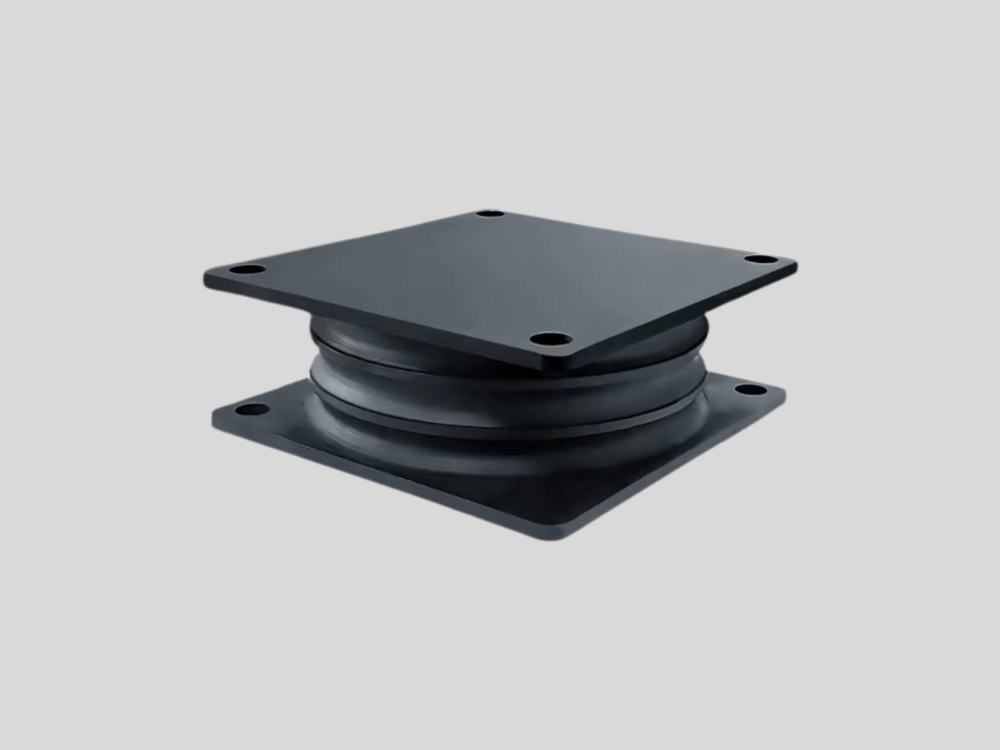

SWA Series Multi-Layer Antivibration Dampers

Exceptional Care Provided by Highly Experienced Dental Professionals

SWA Multi-Layer Antivibration Dampers

The SWA multi-layer damper stands out significantly from traditional rubber mounts in both design and performance. While standard rubber mounts are typically made from a single molded rubber component, they can suffer from fatigue, deformation, or failure when exposed to heavy loads or prolonged vibrations. In contrast, the SWA damper features a composite structure of high-dynamic rubber layers alternated with reinforced steel plates. This "rigid-flexible" design dramatically improves load-bearing capacity, shock resistance, and overall durability, especially under high-impact and high-frequency working conditions. The inclusion of steel plates enhances structural integrity, while the rubber layers provide superior damping and elasticity. As a result, the SWA damper is not only more reliable in tough environments but also offers extended service life and reduced maintenance needs. It is an ideal solution for advanced industrial equipment requiring stable and efficient vibration isolation.

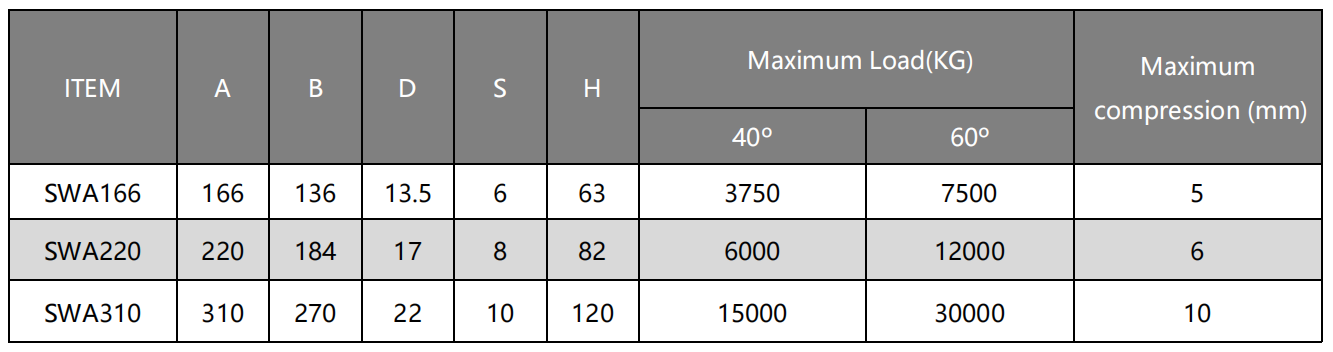

The SWA multi-layer damper is engineered for exceptional load-bearing capabilities, making it suitable for medium to heavy-duty equipment. Each model is carefully designed based on precise calculations that account for both static loads (such as equipment weight) and dynamic forces (such as vibration and impact). Load capacities range from several hundred kilograms to multiple tons, depending on the model. With high vertical stiffness and controlled shear flexibility, the SWA damper maintains its vibration isolation effectiveness even under substantial weight and constant operation. It is widely used in equipment like crushers, vibratory screens, industrial fans, and generators. For accurate selection, we recommend referring to the technical datasheets or contacting our team to help identify the model that best suits your load and installation requirements.

Yes, the SWA damper is specifically built to perform reliably in outdoor and harsh operating environments. This resilience is achieved through careful material selection and robust surface treatment. The rubber compound used is highly weather-resistant, offering excellent resistance to UV exposure, ozone, aging, and extreme temperatures — from as low as -20°C to over 70°C — without compromising elasticity or damping performance. Additionally, the steel components are treated with corrosion-resistant coatings such as phosphating, electrophoretic painting, or zinc plating, ensuring long-term protection against rust and oxidation. Whether in open-pit mining operations, coastal installations, dusty quarries, or humid construction zones, the SWA damper delivers dependable vibration isolation without degradation, helping to protect equipment and maintain operational efficiency even in the most challenging conditions.

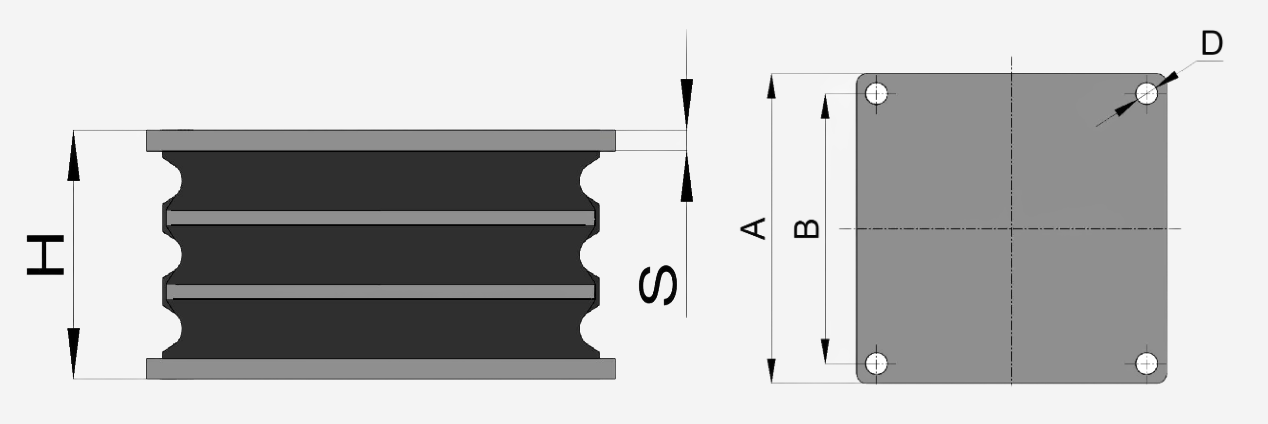

Installation Diagram of SWA Multi-Layer Antivibration Dampers

Parameter Table of SWA Multi-Layer Antivibration Dampers

If you like this Antivibration Dampers but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]