Hydraulic Cone Mounts

Hydraulic Cone Mount – High-Performance Vibration Isolator for Precision Machinery

Hydraulic Cone Mounts

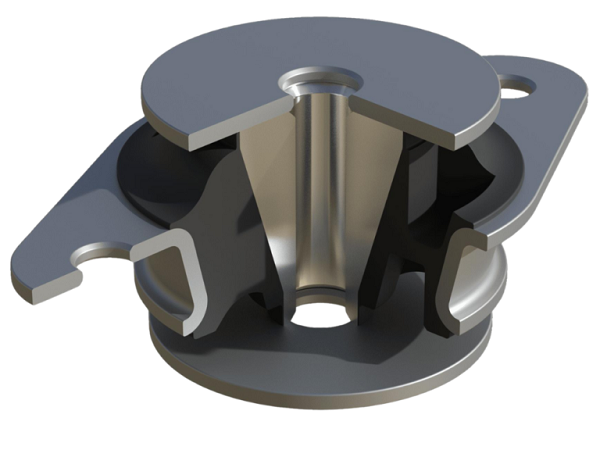

A hydraulic cone mount is an advanced vibration isolation device that integrates a rubber spring element with a hydraulic damping system, designed in a cone shape. The rubber component serves to bear the static load of the equipment while providing inherent elastic properties that absorb low to medium frequency vibrations.

Meanwhile, the hydraulic system contains multiple fluid-filled chambers connected by narrow orifices that force hydraulic fluid to flow during vibration-induced movements. This fluid flow generates damping forces that convert vibration energy into heat, efficiently dissipating it.

The dual mechanism balances the need for soft spring action for isolation and high damping for movement control. This design minimizes vibration transmission to the supporting structure, effectively reducing noise, mechanical wear, and fatigue, and thereby safeguarding the operational integrity and lifespan of critical industrial machinery.

Traditional rubber isolators primarily rely on the material's elasticity to cushion vibrations, but they offer limited damping capabilities. This limitation often results in secondary vibrations or rebounds, which can be detrimental to sensitive equipment. Hydraulic cone mounts overcome these challenges by combining elastic support with hydraulic damping.

The fluid damping mechanism effectively dissipates vibrational energy, especially mitigating high-frequency shocks and transient impacts that rubber alone cannot absorb adequately. Furthermore, hydraulic mounts provide adjustable damping characteristics by varying fluid viscosity and flow path dimensions, allowing tailored vibration isolation for specific applications.

They are typically compact, durable, and capable of handling heavy loads and harsh environments. Their superior control over resonance phenomena and transient motions makes them essential in high-precision or heavy-duty industrial settings, significantly enhancing equipment stability, reducing maintenance costs, and prolonging service life.

Hydraulic cone mounts are widely employed in various heavy industrial and commercial applications where precise vibration control is essential. Common use cases include large generator sets and power plants, compressors, pumps, fans, heating, ventilation, and air conditioning (HVAC) units, construction machinery, marine engines, and offshore oil platforms.

These mounts are particularly valuable in situations involving dynamic and fluctuating loads, frequent start-stop cycles, and exposure to mechanical shocks. By effectively isolating vibration and absorbing transient forces, hydraulic cone mounts prevent structural damage, minimize noise pollution, reduce fatigue failure risks, and improve overall operational reliability.

Their application extends to critical infrastructure and machinery requiring long-term continuous operation with minimal downtime, thus proving indispensable in modern industrial vibration management.

The hydraulic damping mechanism in a cone mount functions by directing hydraulic fluid to flow through strategically designed orifices between interconnected chambers inside the mount. This controlled fluid flow creates viscous resistance, transforming kinetic energy from vibrations into heat energy, which is then dissipated harmlessly.

This energy dissipation process reduces vibration amplitude, prevents excessive oscillation, and stabilizes dynamic movements. The hydraulic system excels during transient events such as equipment start-up, shutdown, or sudden shocks by damping vibration peaks and suppressing overshoot effects that would otherwise stress the machinery.

Additionally, the damping performance can be customized by altering fluid viscosity, chamber volume, and orifice dimensions to match precise vibration frequencies and amplitudes. This tailored damping leads to optimal vibration isolation efficiency, ensuring smoother, quieter, and safer equipment operation across a wide range of industrial environments.

Yes, hydraulic cone mounts are highly customizable to meet the specific vibration isolation requirements of diverse equipment and operational conditions. Customization involves adjusting parameters such as the rubber's hardness and elasticity, hydraulic fluid type and viscosity, the size and shape of fluid chambers, and the design of flow paths within the mount.

These adjustments are made based on detailed data provided by the customer, including equipment weight, expected vibration frequency range, installation constraints, and environmental factors such as temperature and humidity. The goal is to fine-tune both the elastic and damping properties to perfectly match the equipment's dynamic behavior.

This bespoke design process ensures the mount delivers maximum vibration isolation without underperforming or causing excessive stiffness. Our experienced engineering team collaborates closely with clients, providing comprehensive technical support and free design consultation to develop the optimal solution that enhances equipment performance, reduces downtime, and extends operational life.

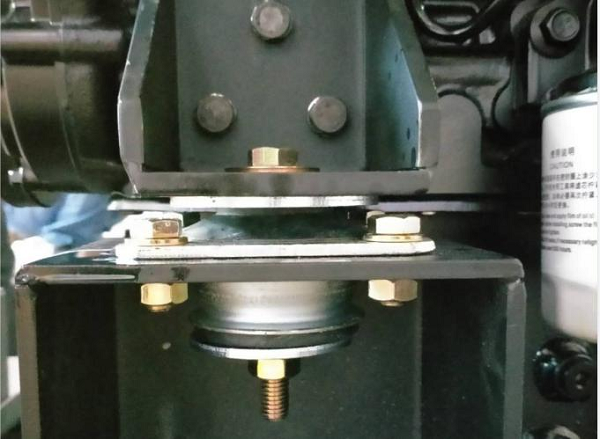

CN Cone Mounts And Application Scenarios Diagram

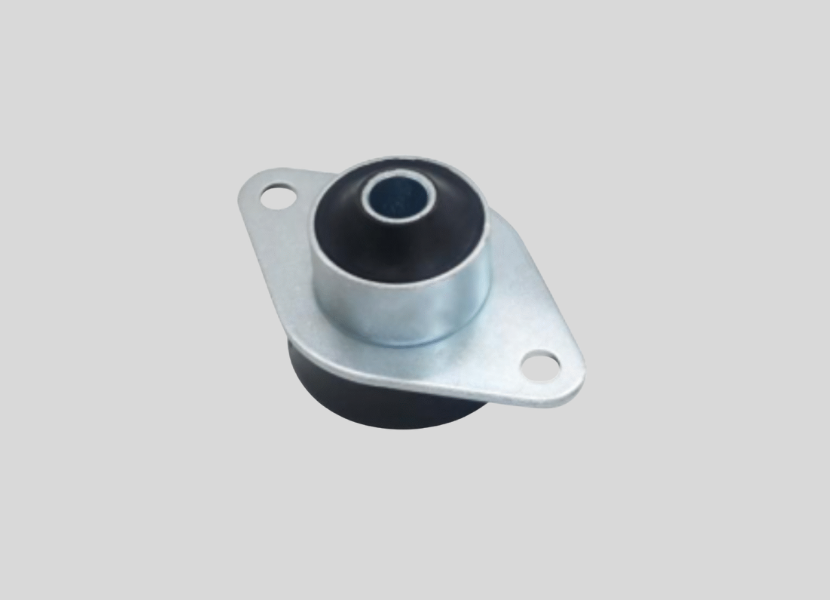

CN Cone Mounts are highly versatile vibration isolators designed to absorb shocks and reduce structure-borne noise in industrial and mechanical systems. Made from high-grade rubber and steel components, they provide excellent axial and radial load resistance. These mounts are particularly suitable for equipment with dynamic loads and frequent vibration cycles.

Typical application scenarios include:

Diesel generator sets

Pumps and compressors

HVAC units

Construction machinery

Marine engines and onboard equipment

The diagram visually presents how CN Cone Mounts are installed in different machinery, helping engineers and maintenance teams select and apply the correct model for maximum efficiency.

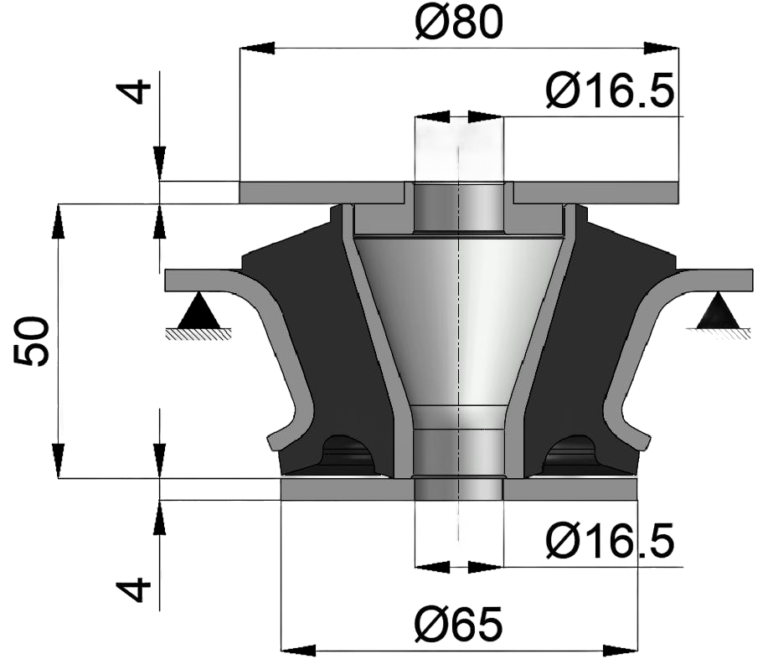

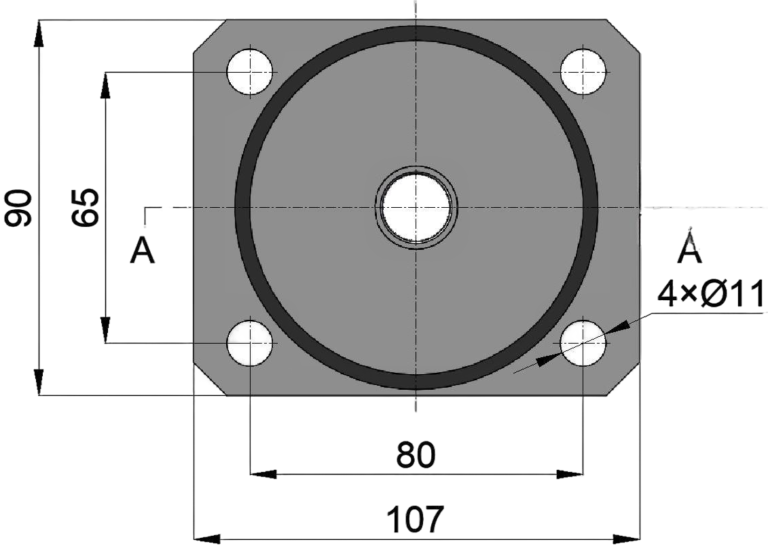

CN7856 Cone Mounts Analysis Diagram

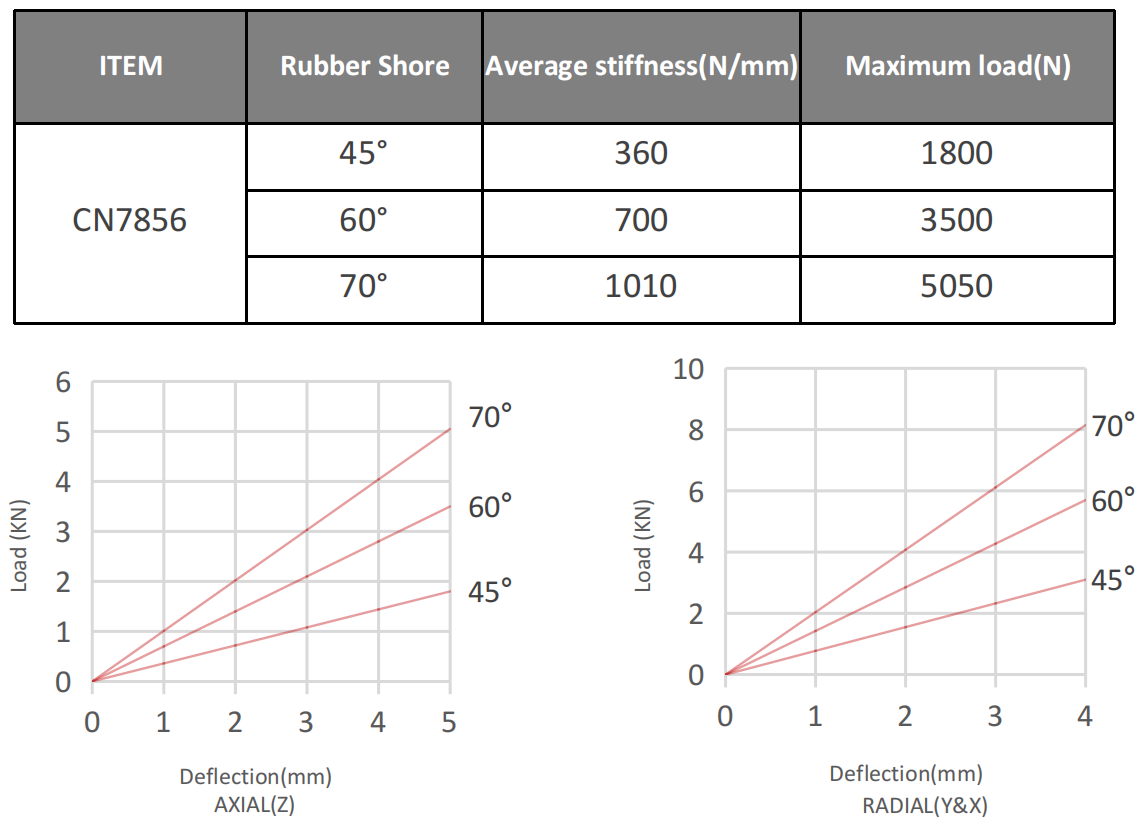

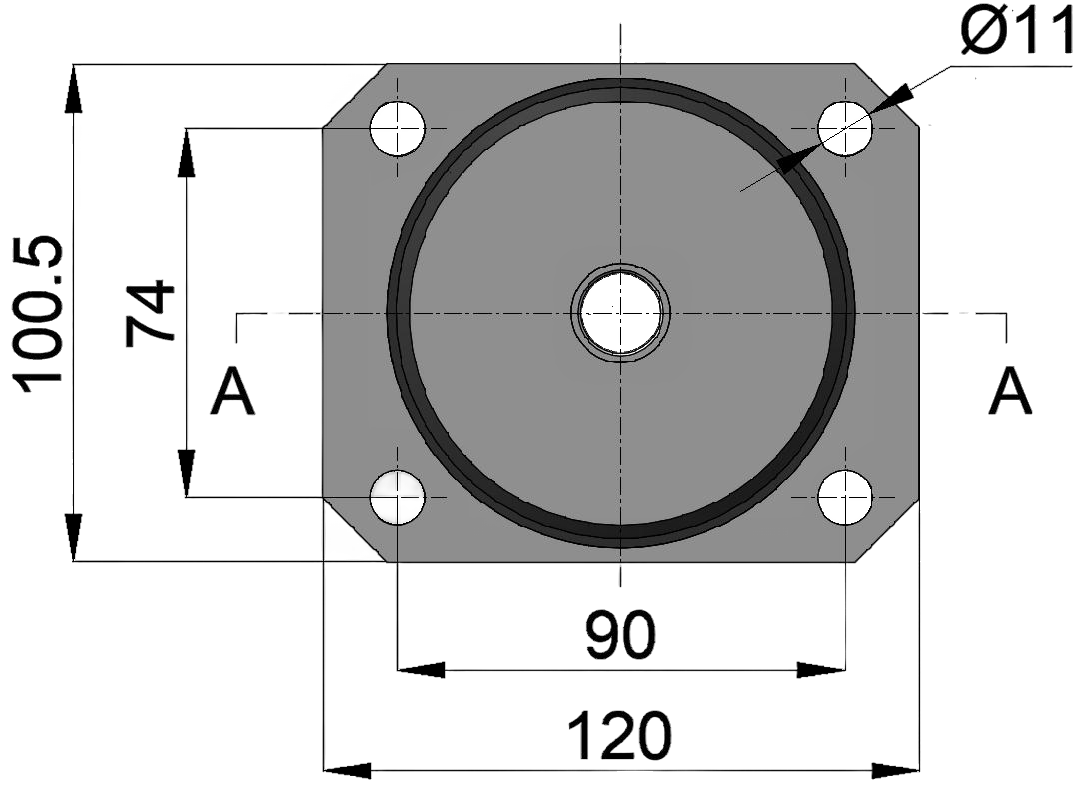

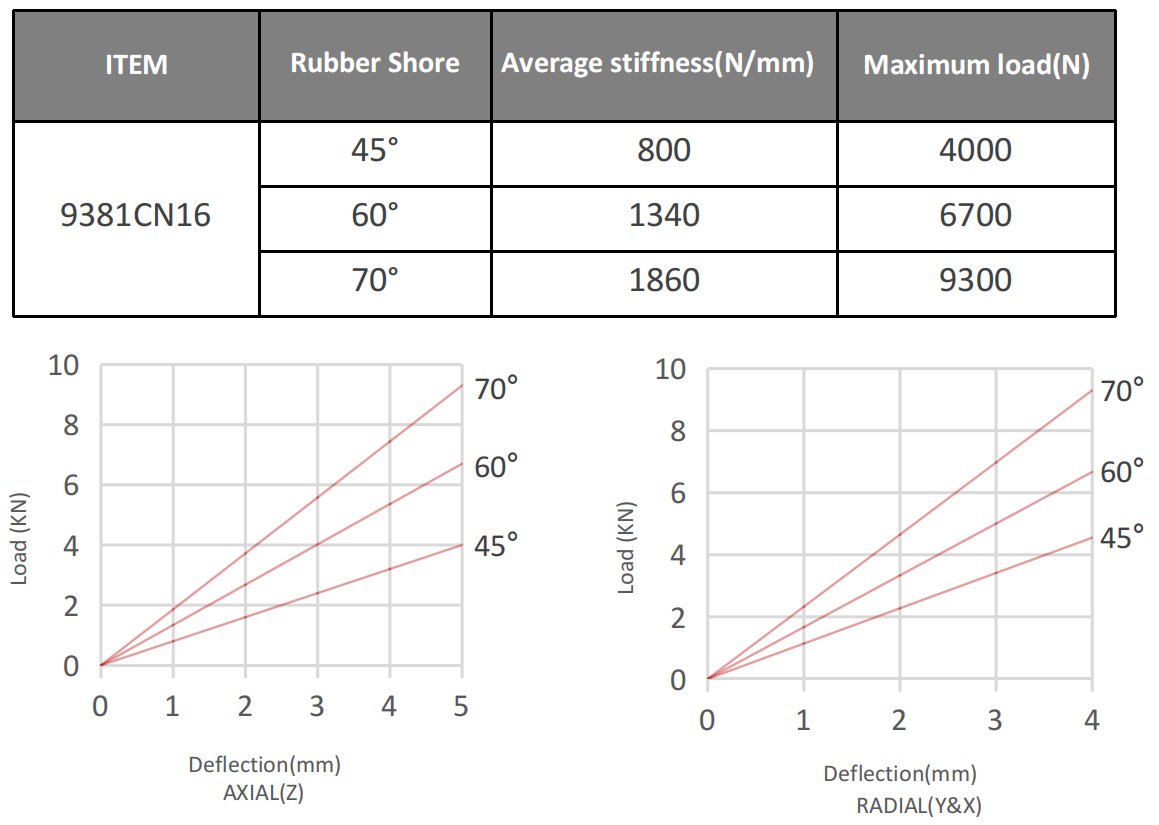

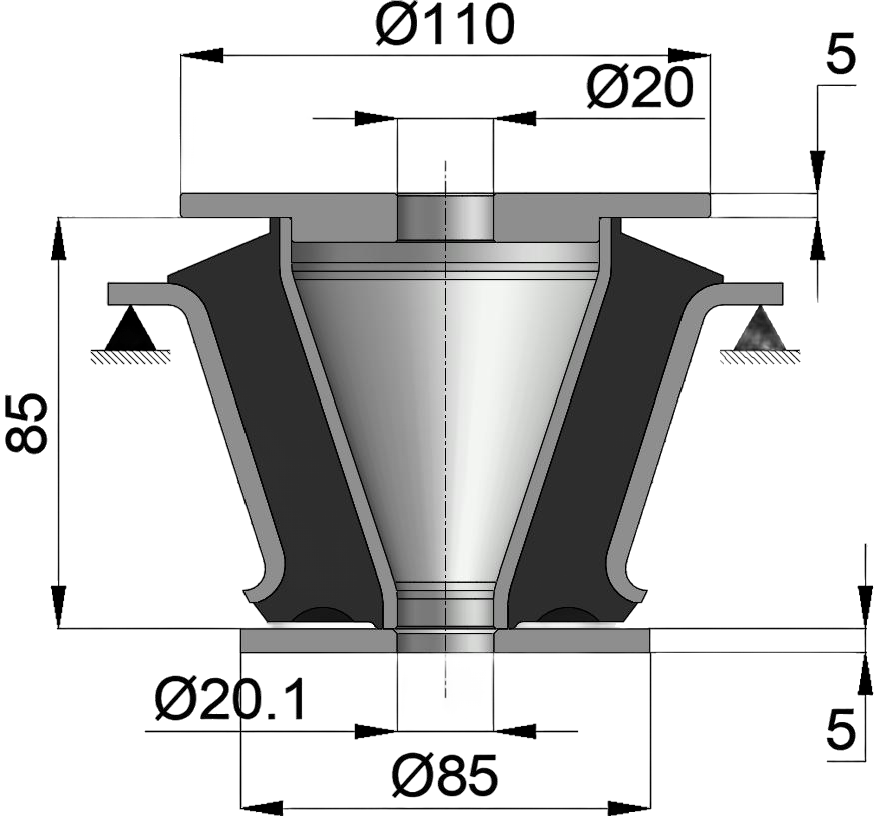

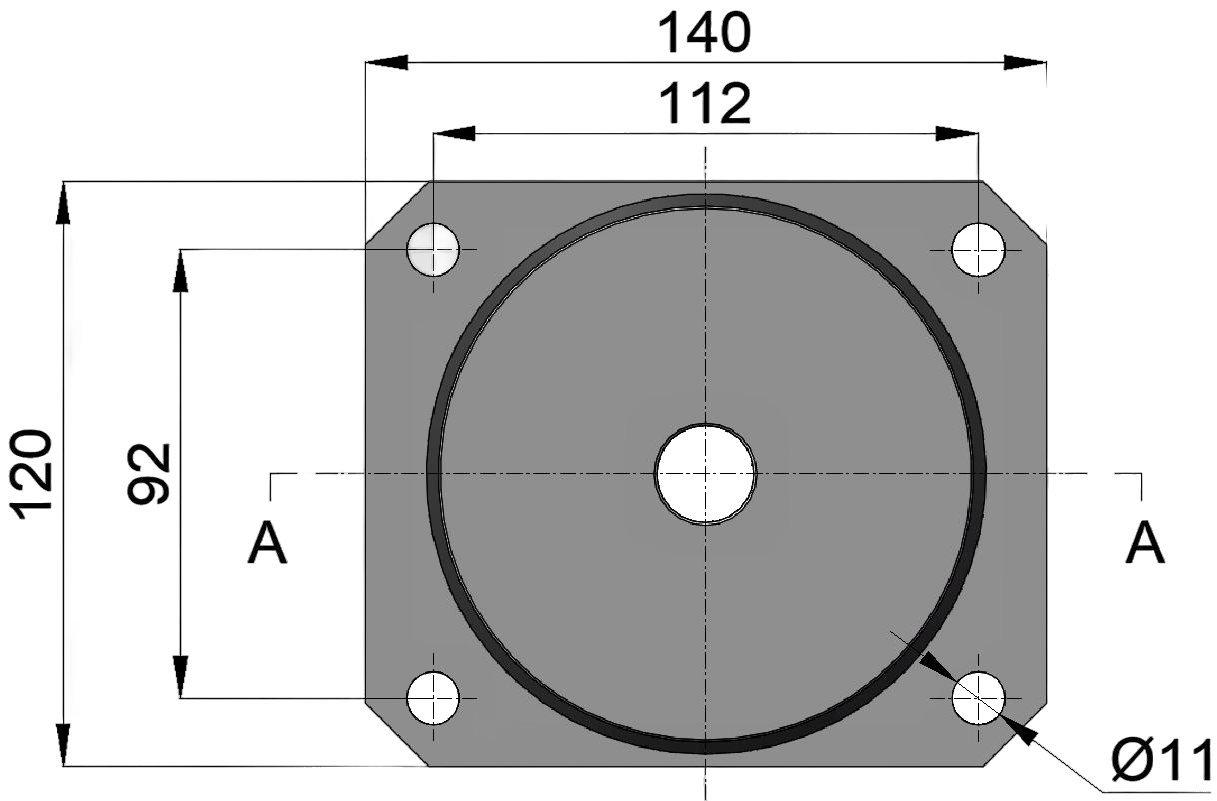

9381CN16 Cone Mounts Analysis Diagram

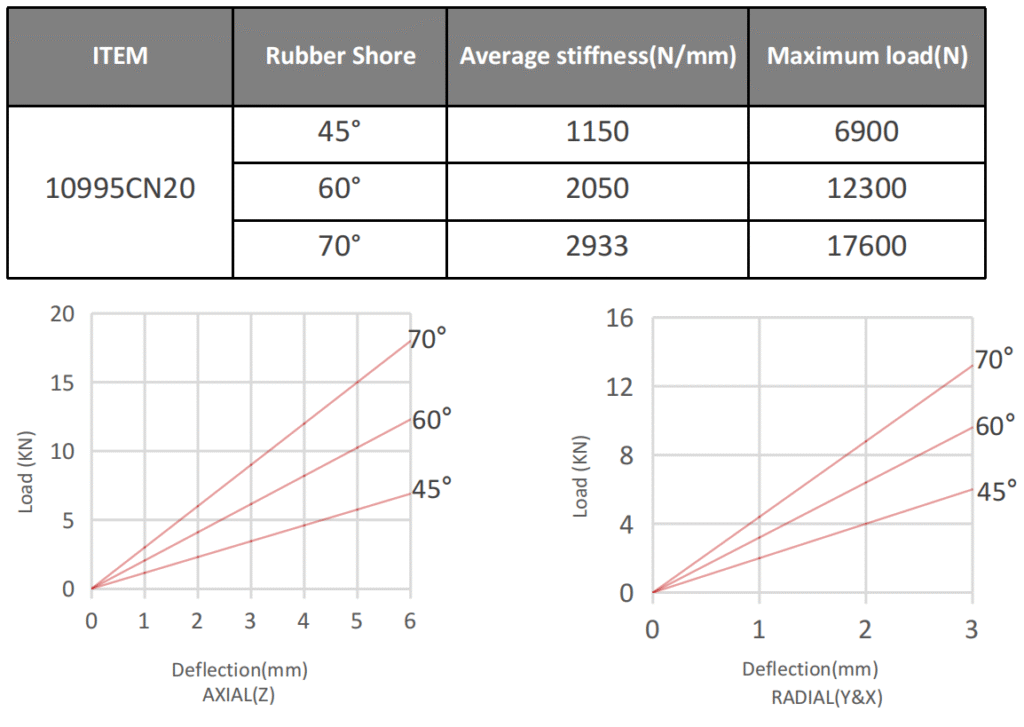

10995CN20 Cone Mounts Analysis Diagram

If you like this CN Series Cone Mounts but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]