CGM-Type Circular Vibration Buffer

Built for high-impact use, the CGM Ring Buffer ensures excellent energy absorption, enhancing equipment life and stability.

CGM-Type Circular Vibration Buffer

The key mechanical properties impacting the vibration isolation performance of the CGM-Type Circular Vibration Buffer include stiffness (spring rate), damping capacity, natural frequency, and fatigue resistance. The elastomer (natural rubber, NBR, or neoprene) provides both elastic deformation and internal energy dissipation (hysteresis), which allows the buffer to absorb and dampen vibrations effectively.

Stiffness defines how much the buffer compresses under load and affects isolation efficiency.

Damping capacity converts vibrational energy into heat, preventing resonance.

Natural frequency is engineered to be below excitation frequencies to avoid amplification.

Fatigue resistance ensures long service life under cyclic loads.

Together, these properties enable effective vibration isolation and shock absorption in demanding industrial and mobile applications.

Unlike conventional vibration isolators that only handle compressive loads, the CGM-Type Circular Vibration Buffer is engineered to resist and absorb dynamic loads in both axial compression and tension (traction) directions due to its ring-shaped elastomer-steel bonded structure.

When subjected to compression, the rubber compresses and deforms, dissipating energy and isolating vibrations.

Under traction or tensile loads (e.g., when parts of the equipment are pulled apart during operation or off-road maneuvers), the buffer’s continuous rubber ring and central steel tube maintain integrity, preventing separation and sustaining load transmission safely.

This bi-directional load handling makes the CGM buffer suitable for applications where vertical loads fluctuate dynamically, such as agricultural machines crossing uneven terrain or military vehicles experiencing sudden jolts. This ability prevents excessive mechanical stress, enhances safety margins, and prolongs equipment lifespan by maintaining vibration isolation throughout complex load cycles.

The design of the CGM-Type buffer takes into account several potential failure modes to ensure operational reliability:

Rubber shear failure: Excessive shear deformation can cause internal cracks or material rupture. To mitigate this, the rubber compound formulation balances elasticity and tensile strength, and the thickness/geometry of the rubber layer is optimized to limit shear strain during peak loads.

Fatigue cracking: Repeated cyclic loading can initiate micro-cracks that propagate over time. High-quality vulcanized natural rubber or synthetic alternatives with proven fatigue resistance are used to extend service life. Accelerated fatigue testing simulates millions of cycles to validate performance.

Delamination between rubber and steel: The bond between the elastomer and metal washer/tube is critical. Industrial vulcanization processes with adhesion promoters ensure a strong, durable bond that prevents separation under dynamic loads.

Corrosion of metal components: Steel parts are zinc-plated following CE and RoHS standards and are chrome VI free to prevent rust and environmental hazards. Proper surface treatment extends lifespan in corrosive environments.

Compression set: Over time, rubber can experience permanent deformation reducing effectiveness. The chosen materials and vulcanization techniques minimize compression set, preserving isolation efficiency.

By addressing these failure modes in material selection, design, and quality control, the CGM buffer offers fail-safe operation even in challenging industrial and mobile equipment scenarios.

Environmental durability depends heavily on the rubber compound:

Natural Rubber (NR): Excellent elasticity and mechanical resilience but sensitive to oil, fuels, ozone, UV radiation, and extreme temperatures. Ideal for general-purpose vibration isolation in protected environments.

Nitrile Butadiene Rubber (NBR): Offers superior resistance to oils, greases, fuels, and hydraulic fluids, making it suitable for use near engine compartments, hydraulic systems, or fuel lines. NBR has moderate weathering resistance.

Neoprene (CR): Provides enhanced resistance to weathering, ozone, UV exposure, flame, and moderate chemicals. Suitable for outdoor applications and harsh environments such as military vehicles and off-road equipment.

Operating temperature ranges typically span from -30°C to +80°C for NR, and extended ranges for NBR and CR variants. Extreme cold or heat reduces elasticity and lifespan; thus, selecting the appropriate compound based on the operating environment is essential. Additionally, zinc plating on steel parts protects against corrosion in humid or salt-exposed conditions.

Correct installation requires:

Using specified bolt sizes and torque to avoid over-compression or loosening.

Ensuring precise alignment to prevent uneven stress.

Preparing clean, smooth mounting surfaces.

Regular inspection for rubber degradation, corrosion, and bolt tightness.

Avoiding load beyond design limits.

Proper installation and maintenance maximize buffer life and vibration isolation efficiency.

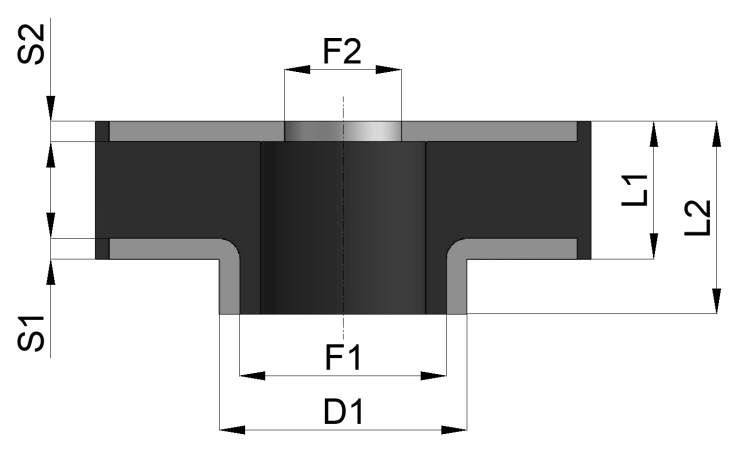

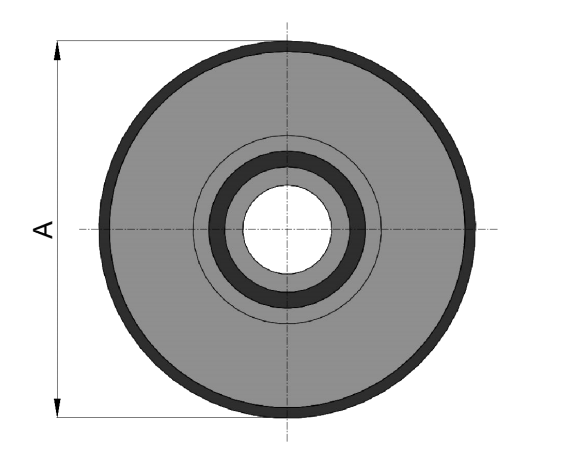

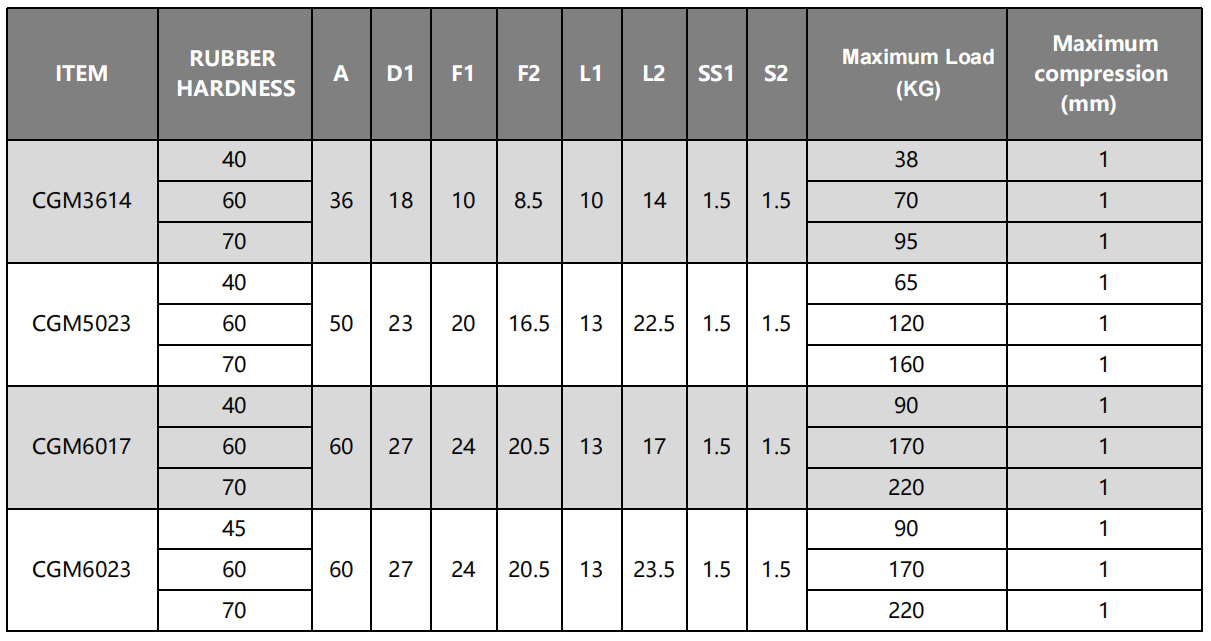

CGM Buffer Series Analysis Diagram And Specifications

We are a professional manufacturer with over 30 years of experience, specializing in the development and production of various types of anti-vibration mountings. Our products are widely used in central air conditioning systems, fan equipment, generator sets, and various industrial machinery. With reliable quality and excellent vibration isolation performance, we have earned the trust and praise of customers both at home and abroad.

Equipped with advanced automated equipment, our factory also offers customized non-standard solutions to quickly meet your diverse needs.

If you would like to know more about product drawings, technical specifications, or pricing, please feel free to contact us anytime at: [email protected]