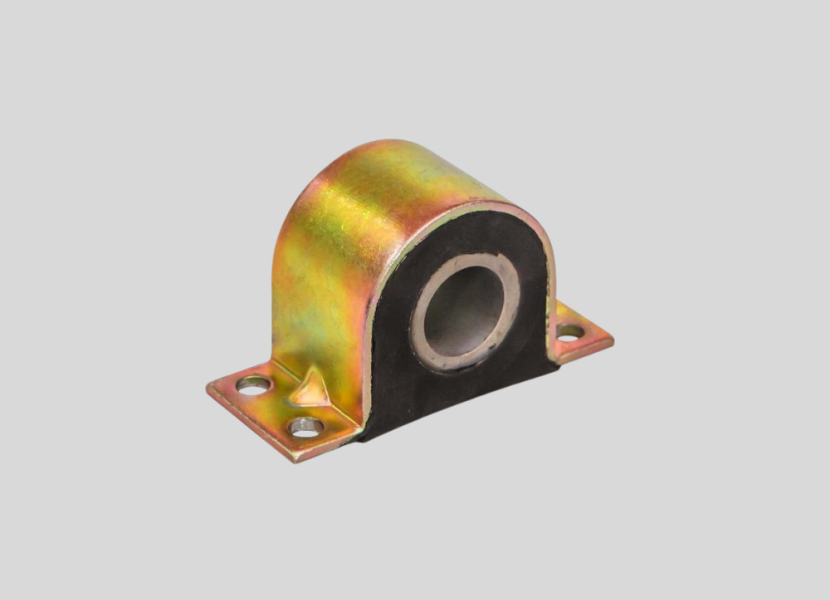

A7 Type Suspension Stabilizer Bar Bushing

A7 Suspension Stabilizer Bar Bushing – Durable Rubber Mount for VW Passat, Tiguan & Audi Q3 | Reliable Anti-Roll Performance

A7 Type Suspension Stabilizer Bar Bushing

The A7 bushing acts as a flexible mounting point that securely attaches the stabilizer (sway) bar to the vehicle chassis, enabling the bar to effectively counteract body roll.

By reducing lateral body sway during cornering and uneven road surfaces, it enhances vehicle handling stability, contributing to safer driving dynamics.

It maintains correct suspension geometry by keeping the stabilizer bar aligned, preventing misalignment-related issues such as uneven tire wear or suspension component stress.

The bushing also isolates and absorbs vibrations and impacts transmitted from road irregularities, significantly improving ride comfort and reducing noise inside the cabin.

Additionally, it protects metal components from direct contact, preventing corrosion, wear, and mechanical damage.

By cushioning the connection between the stabilizer bar and chassis, the bushing dampens vibrations and shock loads from road irregularities, resulting in a smoother, quieter ride experience.

It prevents metal-to-metal contact which could cause squeaking, rattling, or knocking noises, enhancing cabin comfort and reducing driver distraction.

The reduced body roll provided by the bushing increases tire contact patches during cornering, improving traction, steering response, and braking stability.

It helps maintain consistent suspension geometry, preventing accelerated wear of suspension components such as control arms, ball joints, and tie rods, thus enhancing overall vehicle reliability and safety.

By preserving vehicle handling characteristics, the bushing contributes to driver confidence and reduces the risk of loss of control in emergency maneuvers.

Noticeable symptoms include increased vehicle body roll during turns, excessive sway, or instability at higher speeds, which indicate reduced bushing effectiveness.

Unusual noises such as clunks, rattles, or squeaks originating from the suspension area during driving over bumps or uneven roads suggest worn or damaged bushings.

Visual inspection may reveal cracks, tears, hardening, or deformation of the rubber material due to aging or exposure to harsh conditions.

Excessive free play or movement of the stabilizer bar when manually checked can indicate bushing wear or failure.

Tire wear patterns, such as uneven or rapid wear, can sometimes result from suspension misalignment caused by deteriorated bushings.

It is recommended to have bushings inspected during routine maintenance intervals or if any of the above symptoms appear, generally every 30,000 to 50,000 kilometers depending on driving conditions.

Installation should follow manufacturer torque specifications precisely to avoid over-tightening or under-tightening, which can lead to premature wear or noise issues.

Proper alignment of the bushing and stabilizer bar is essential to ensure effective vibration isolation and suspension performance.

Some bushing types may require the application of a compatible lubricant or anti-squeak compound on the contact surfaces to reduce friction and noise; always consult product-specific guidelines.

Replacement of bushings is generally recommended in pairs (both sides of the vehicle) to maintain symmetrical suspension behavior and balanced handling.

Use original or high-quality aftermarket mounting brackets, clamps, and hardware to preserve fitment accuracy and durability.

Post-installation wheel alignment check is advisable to confirm suspension geometry is within factory tolerances, optimizing tire life and vehicle control.

Regular inspections during scheduled vehicle servicing can help detect early wear signs and prevent suspension failures.

The A7 bushing is typically made of high-grade natural rubber (NR) or neoprene rubber (chloroprene, CR), each selected for specific performance characteristics.

Natural rubber offers excellent elasticity, tensile strength, and resilience, making it ideal for absorbing vibrations and dynamic loads under typical automotive conditions.

Neoprene rubber excels in resistance to oils, greases, ozone, UV radiation, and extreme temperatures, making it suitable for harsher environments or applications exposed to chemicals and weathering.

Both materials are engineered to resist fatigue, cracking, and deformation caused by continuous mechanical stresses, ensuring prolonged service life.

The rubber compounds are precisely molded to maintain dimensional stability, allowing tight fit and consistent performance even under high-frequency vibrations.

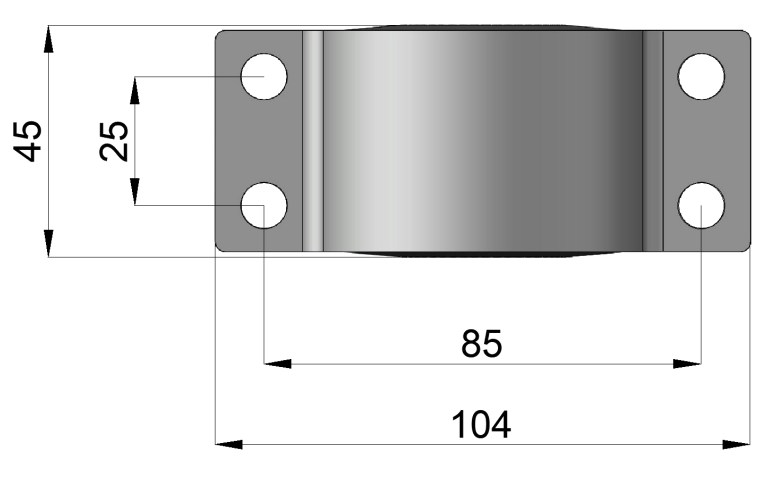

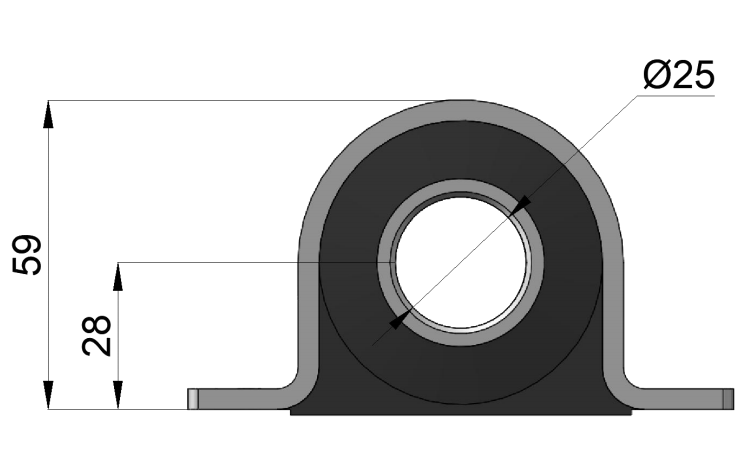

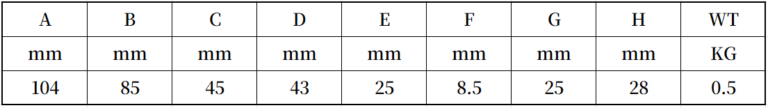

A7 Type Suspension Stabilizer Bar Bushing Drawing

If you like this A7 Type Suspension Stabilizer Bar Bushing but have any concerns or are not fully satisfied with certain aspects, feel free to contact us with your feedback. We can customize it by creating a new mold based on your specific requirements. Our professional engineers will provide a free design service!

For any inquiries, please contact us at: [email protected]